Liftably-slantwise conveying mechanism

A technology of conveying mechanism and turbine, which is applied in the field of parts conveying, can solve problems such as inclined positioning, and achieve the effect of accurate inclined positioning and accurate inclined angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

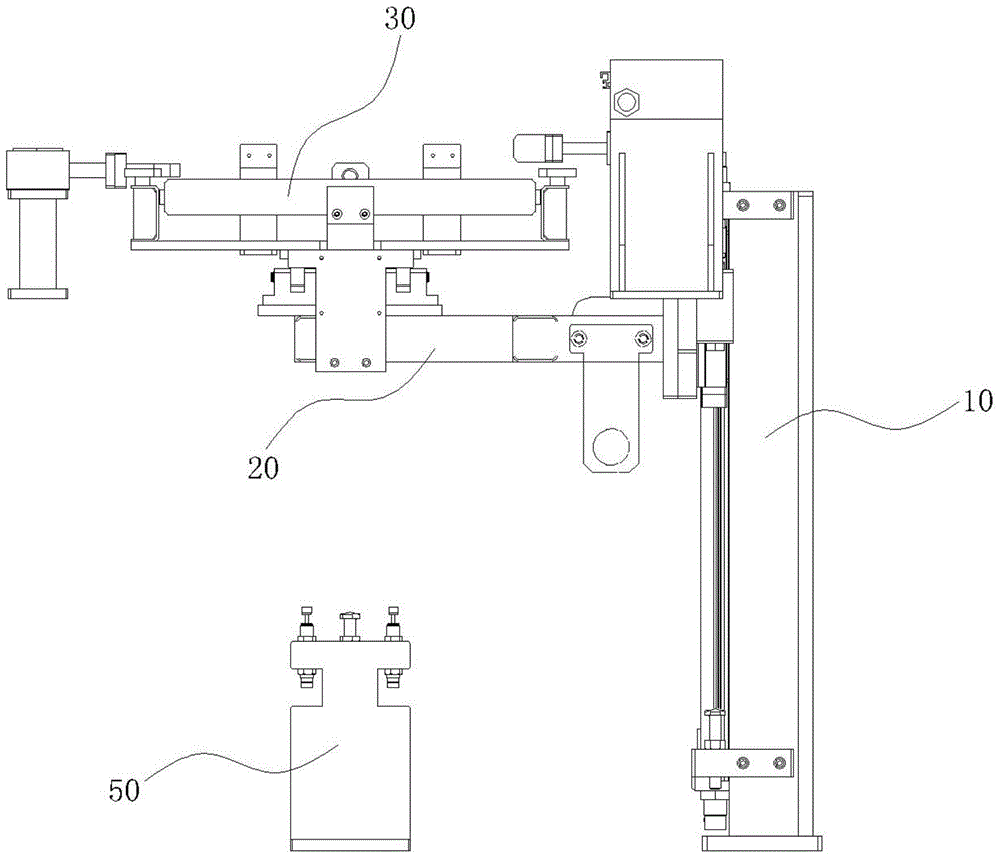

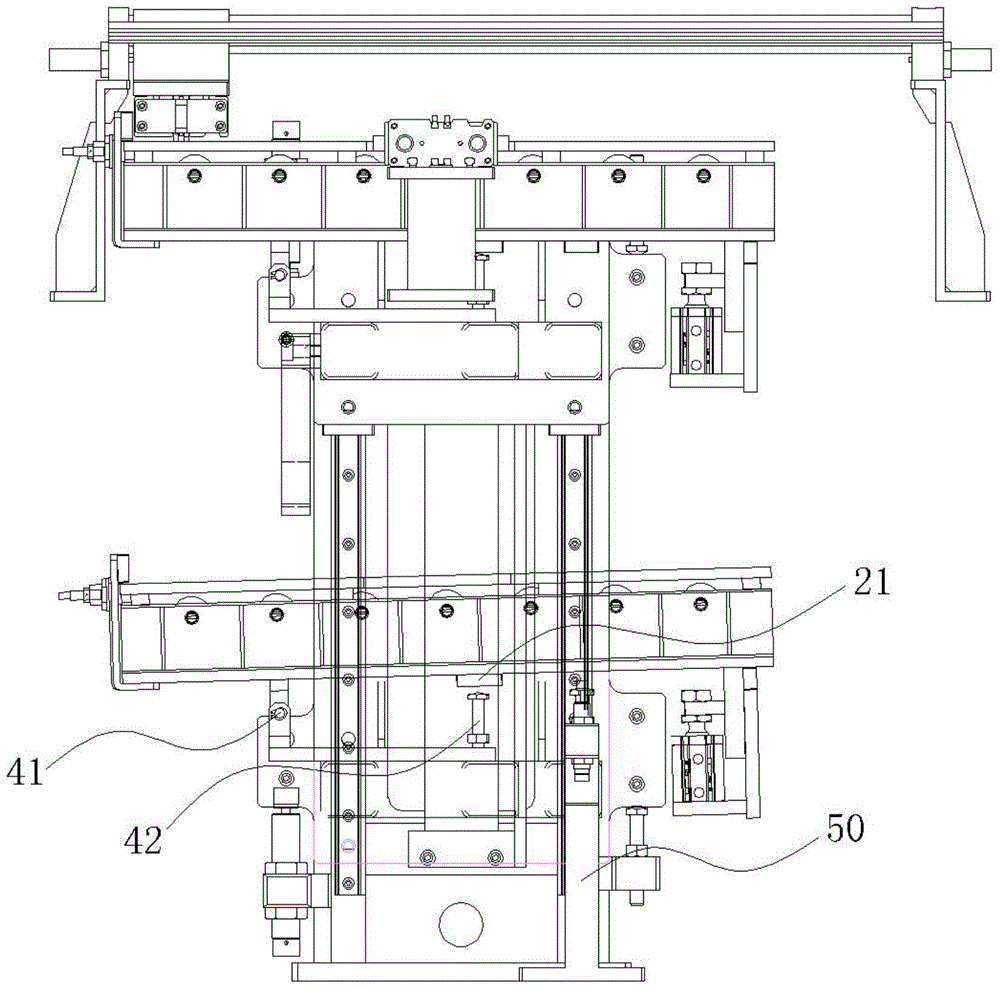

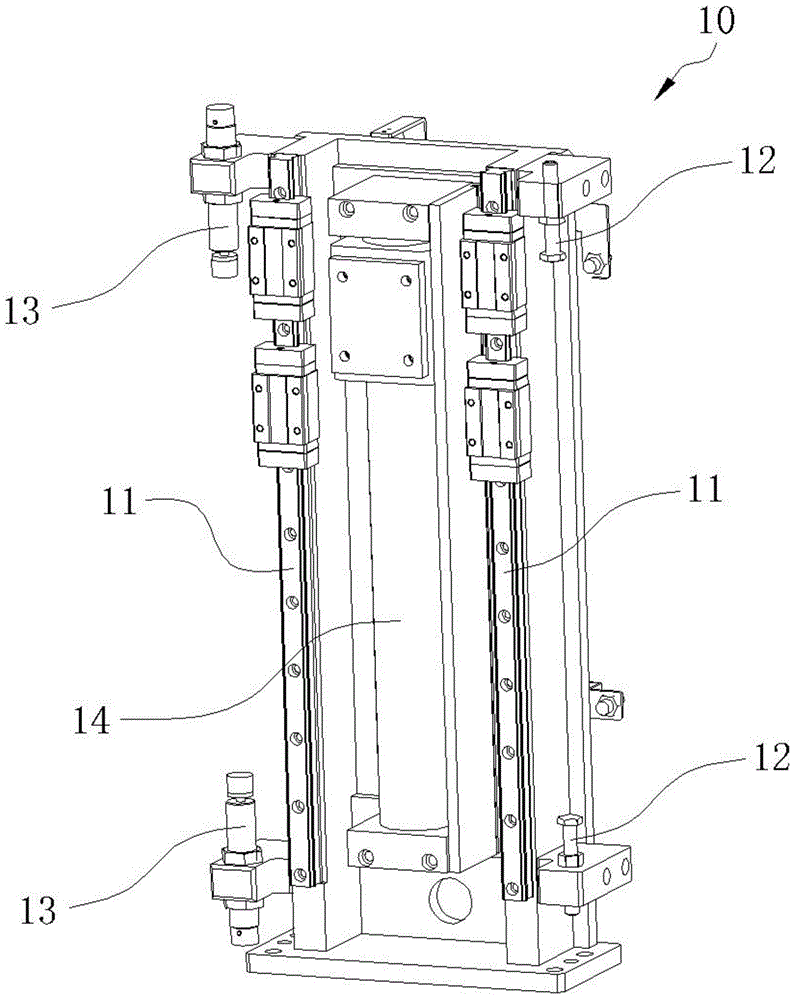

[0028] Such as Figure 1 to Figure 5 As shown, a transport mechanism capable of lifting and tilting includes a support 10 equipped with a cylinder 14, and a lifting platform 20 is installed on the support 10. The support 10 includes a linear guide rail 11, and the linear guide rail 11 is vertically installed on the On both sides of the vertical direction of the support 10, positioning screws 12 and buffers 13 are installed at the upper and lower ends of the linear guide rail 11, and the lifting platform 20 performs lifting action along the linear guide rail 11, and is positioned between the positioning screws 12 and the buffer. 13 actions within a limited range.

[0029] A roller frame 30 is installed on the lifting frame 20, and the roller frame 30 is connected with the lifting frame 20 through a hinge 41 and a set screw 42, and the hinge 41 and the set screw 42 are respectively located near the two ends below the roller frame 30. , the positioning screw 42 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com