A rigid cleaning machine

A kind of cleaning machine, rigid technology, applied in general water supply saving, cleaning of open water surface, water conservancy projects, etc., can solve the problems of poor cleaning effect, low insertion force, and inability of grab-type cleaning machine to clean, etc. , to achieve the effect of good cleaning effect, large insertion force, high rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

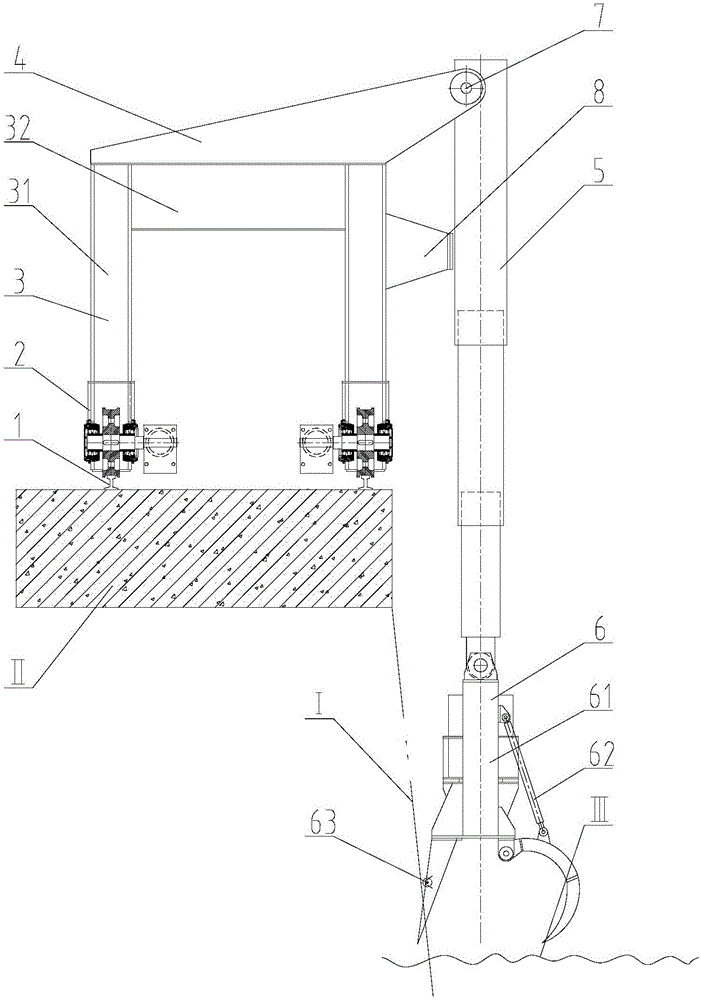

[0021] Such as figure 1 As shown, the trash rack I is located at the bottom side of the foundation II, and there is a certain angle between the trash rack I and the water surface III. 5 is located on the outside of the two uprights 31 in the door frame 3 .

[0022] Since the telescopic sleeve 5 and the grab mechanism 6 are all located on one side of the door frame 3, a rail clamp is provided on the running mechanism 2 walking on the rail 1 to ensure that the door frame 3 on the running mechanism 2 does not fall under the action of external force. overturned.

Embodiment 2

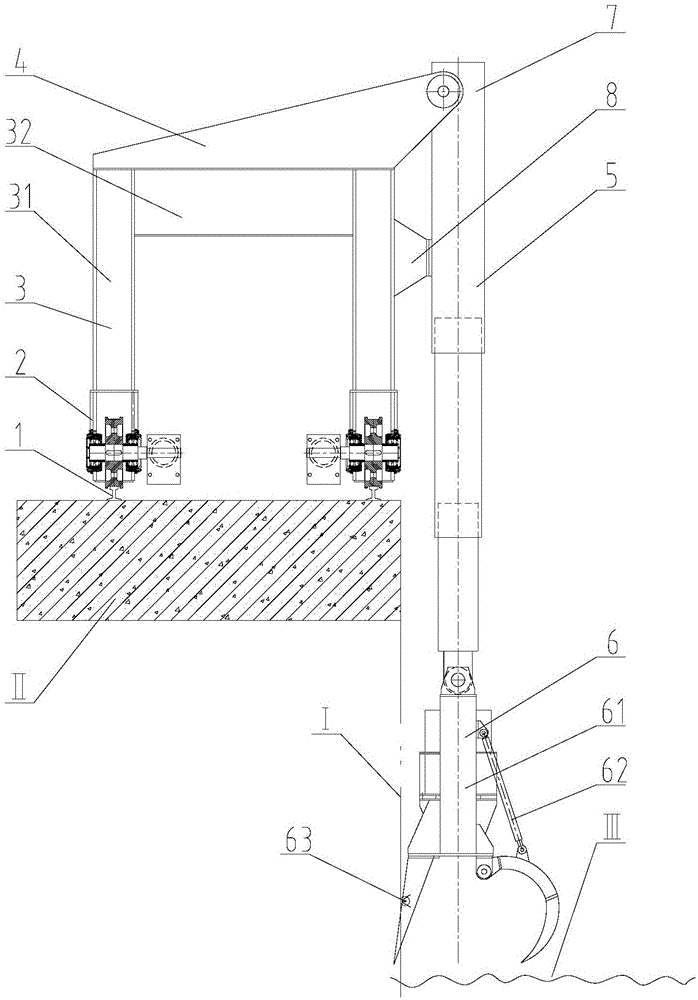

[0024] Such as figure 2 As shown, the trash rack I is located at the bottom side of the foundation II, and is installed vertically between the trash rack I and the water surface III, the fulcrum fixing plate 4 is fixedly connected to the upper surface of the beam 32 in the door frame 3, and the telescopic sleeve 5 is located at the door The outer sides of two columns 31 in the frame 3.

[0025] Since the telescopic sleeve 5 and the grab mechanism 6 are all located on one side of the door frame 3, a rail clamp is provided on the running mechanism 2 walking on the rail 1 to ensure that the door frame 3 on the running mechanism 2 does not fall under the action of external force. overturned.

Embodiment 3

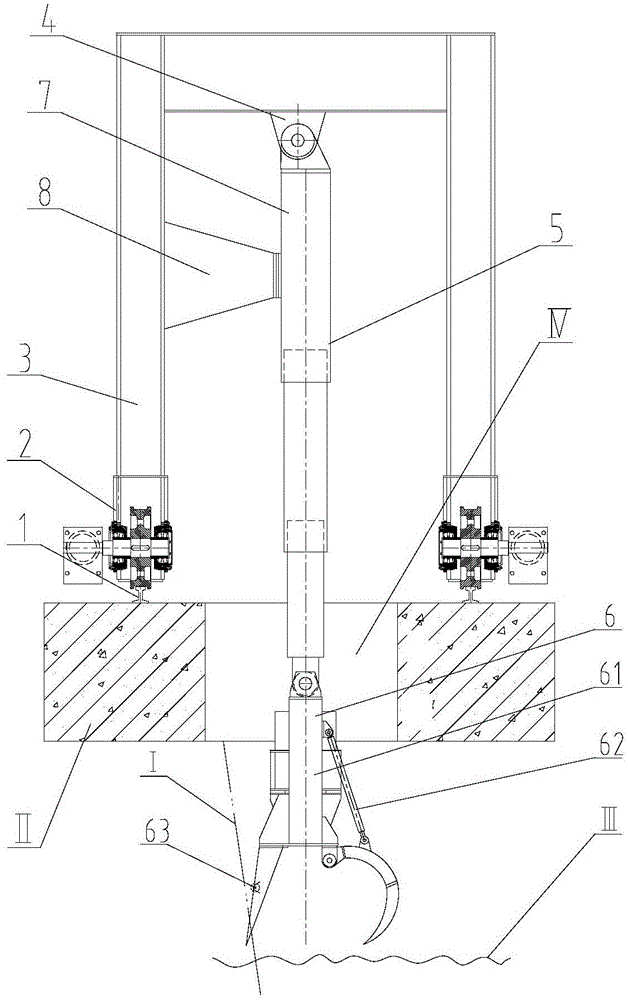

[0027] Such as image 3 As shown, there is a through hole IV through the foundation II, the trash rack I is located at the bottom of the through hole IV in the foundation II, the trash rack I and the water surface III are installed at a certain angle, and the fulcrum fixing plate 4 is fixedly connected On the lower surface of the beam 32 in the door frame 3, the telescopic sleeve 5 is located between the two columns 31 in the door frame 3 and passes through the through hole IV.

[0028] Since the telescopic sleeve 5 and the grab mechanism 6 are all located in the middle of the door frame 3, the door frame 3 on the running gear 2 is not prone to overturning, so a rail clamp can be set on the running gear 2 walking on the rail 1, or not. Set up rail clamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com