A Time-varying Failure Rate Analysis Method for Dynamic Coupling of On-orbit Space Flexible Gear Mechanism

A time-varying failure rate, flexible gear technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low reliability calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0137] Example description:

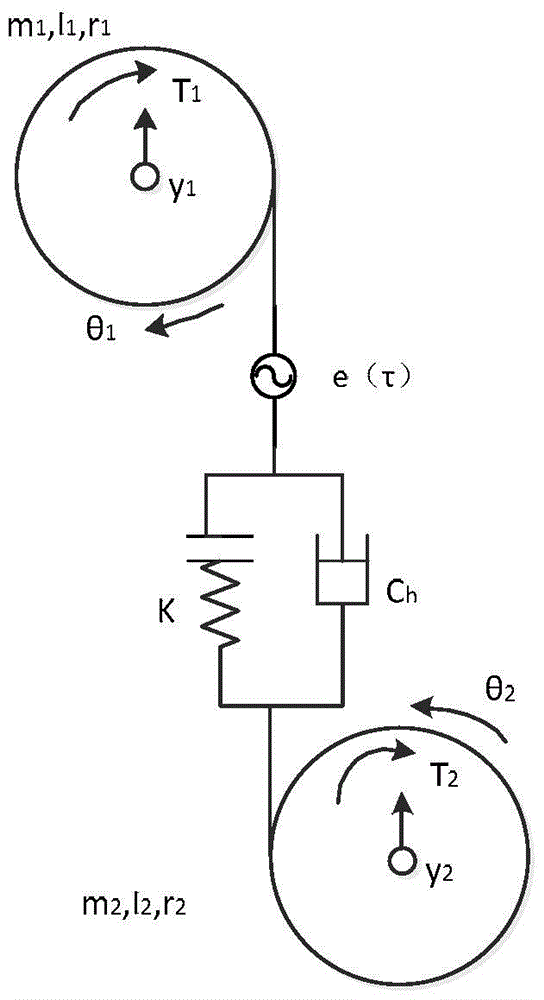

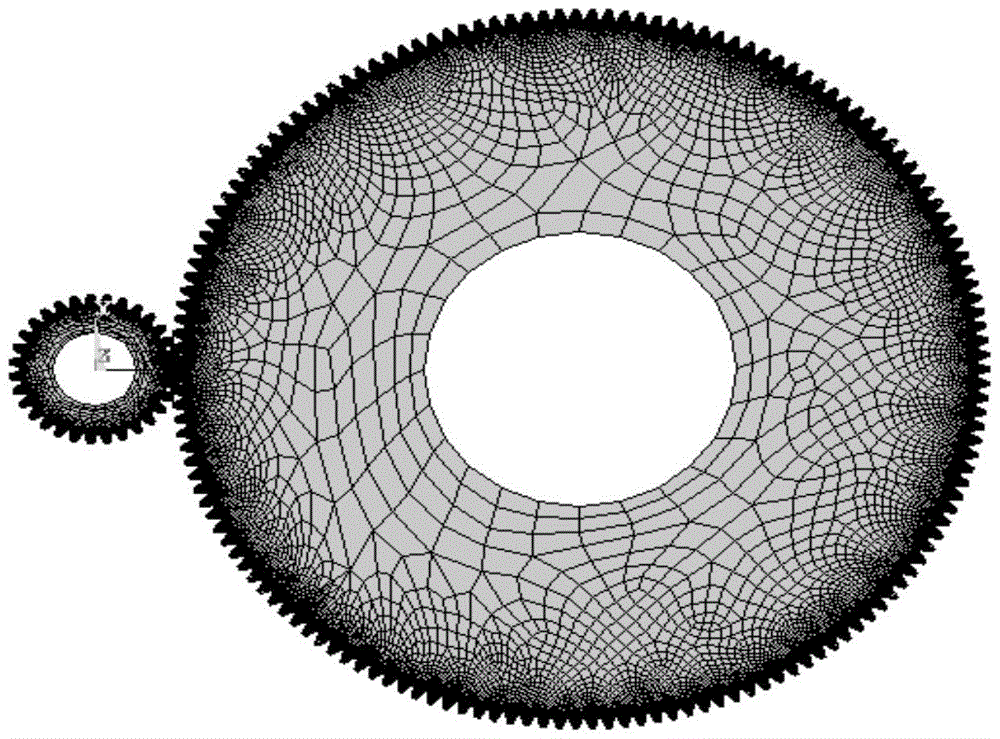

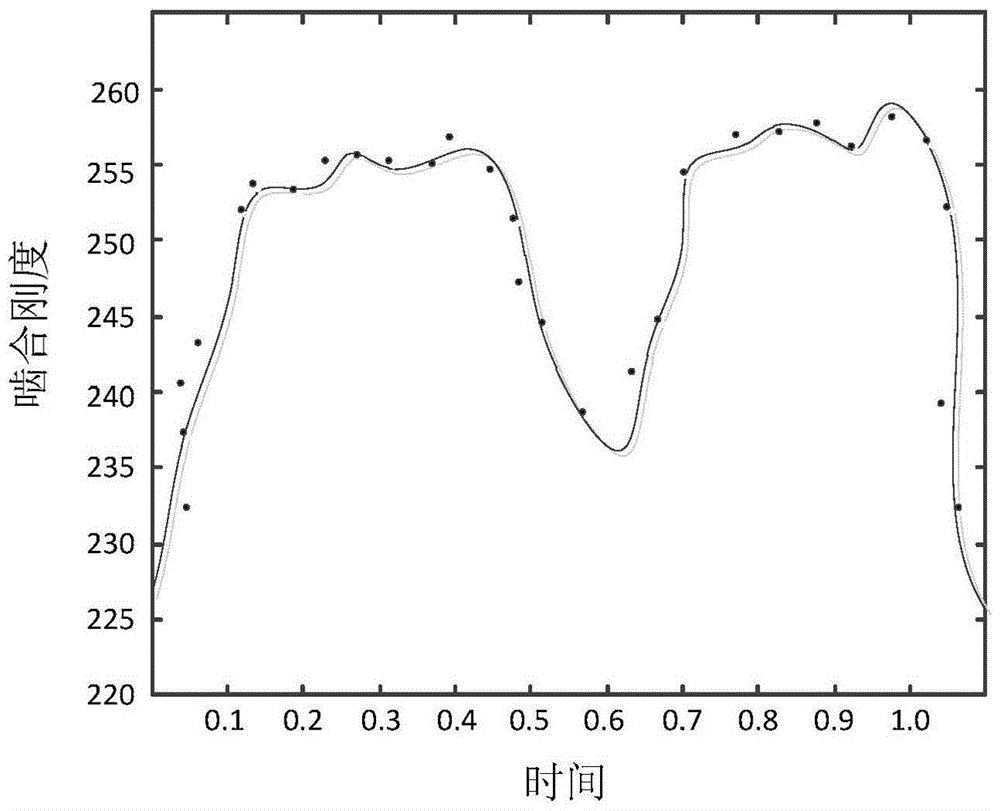

[0138] According to the relevant parameters of the gear and the shaft in the space flexible gear mechanism on orbit, the nonlinear dynamic equation of the coupling between the gear and the flexible shaft is established by using the method proposed by the present invention, and the time-varying reliability analysis is performed on the gear meshing to obtain the failure rate and reliability The time-varying characteristics change with time, and finally the accuracy and feasibility of the present invention are verified by Monte Carlo method.

[0139] For the gear meshing process of the elastic deformation of the elastic body of the space flexible gear mechanism on orbit, the key technologies and difficulties of the time-varying reliability analysis of the space flexible gear mechanism can be summarized as follows:

[0140] 1) Establishment of nonlinear dynamic equations for gear and flexible shaft coupling

[0141] Radial force will inevitably be ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com