Crystal boat for semiconductor furnace tube

A semiconductor and furnace tube technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as improving thermal stress deformation of wafers and chromatic aberration defects, avoid chromatic aberration defects, improve yield, Reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

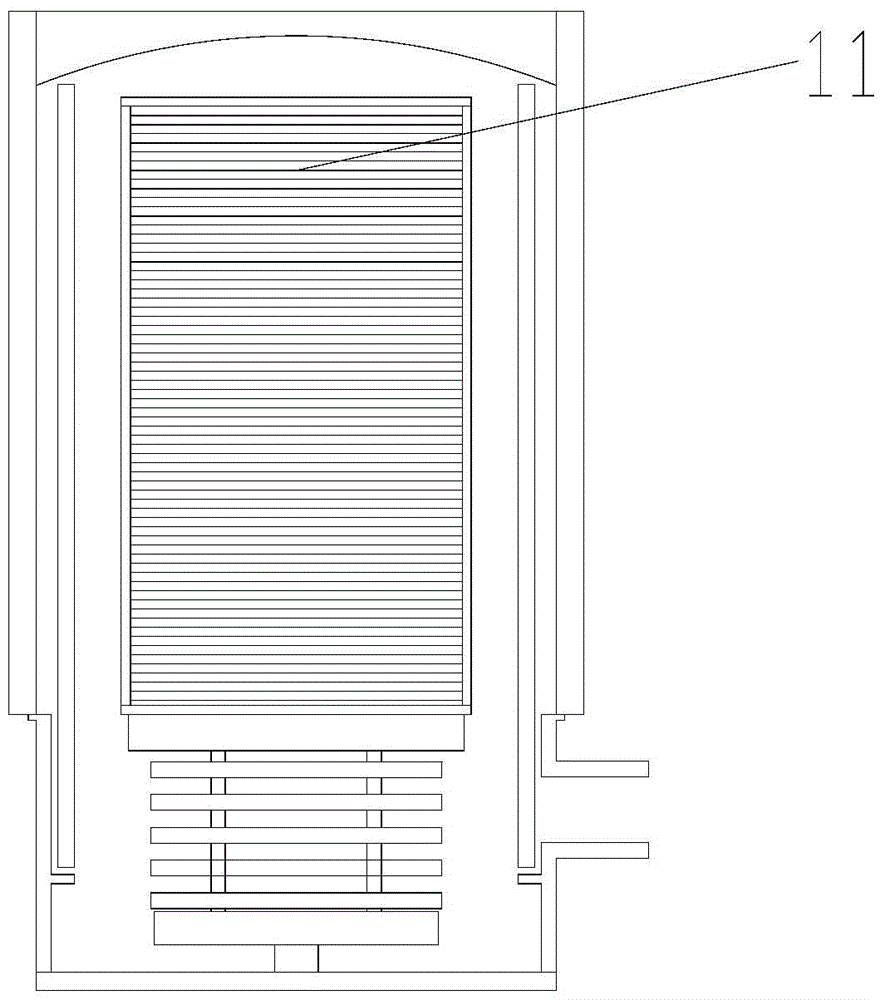

[0026] The invention provides a crystal boat for a semiconductor furnace tube, which can be applied to processes with technology nodes of 90nm, 65 / 55nm, 45 / 40nm, 32 / 28nm, greater than or equal to 130nm, and less than or equal to 22nm; it can be applied to the following technical platforms : Logic, Memory, RF, HV, Analog / Power, MEMS, CIS, Flash and eFlash.

[0027] The core idea of the present invention is to reduce the deformation of the wafer under high temperature conditions by increasing the area of the supporting feet in the wafer boat that are in contact with the wafer, and the specific implementation method is as follows:

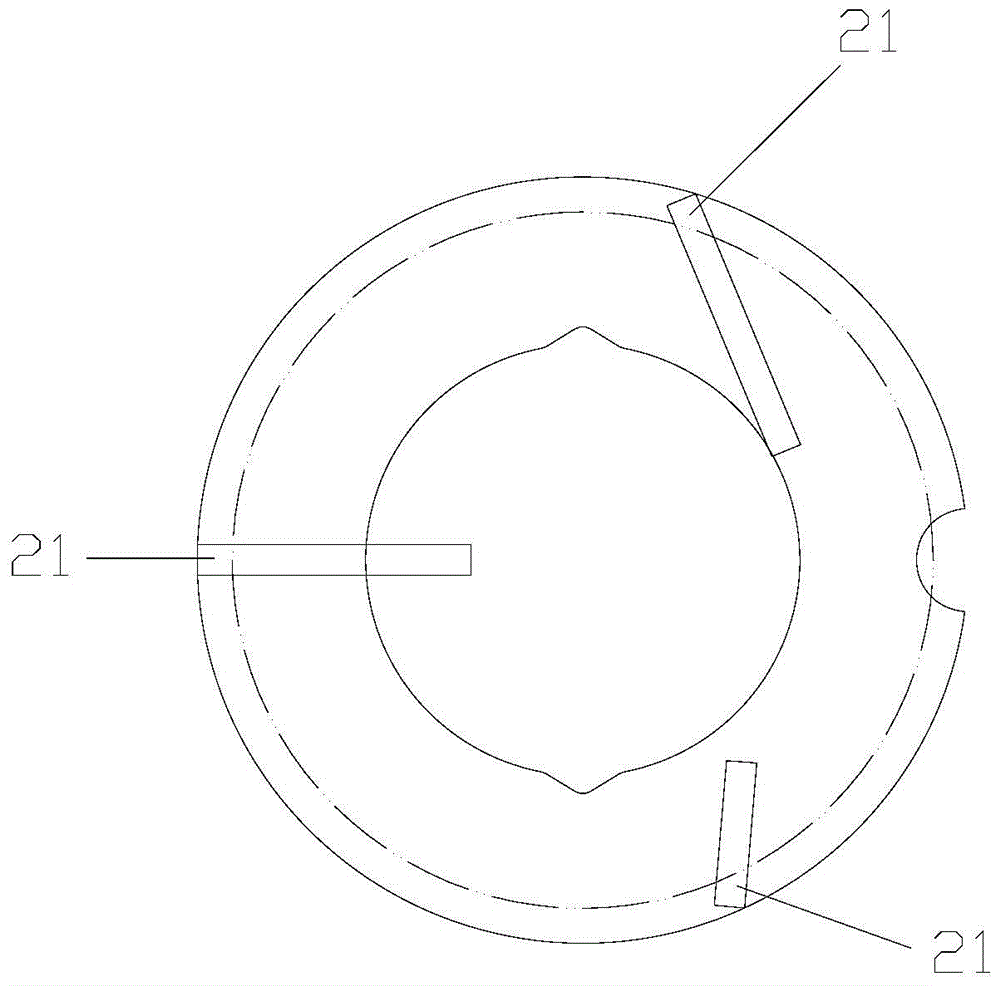

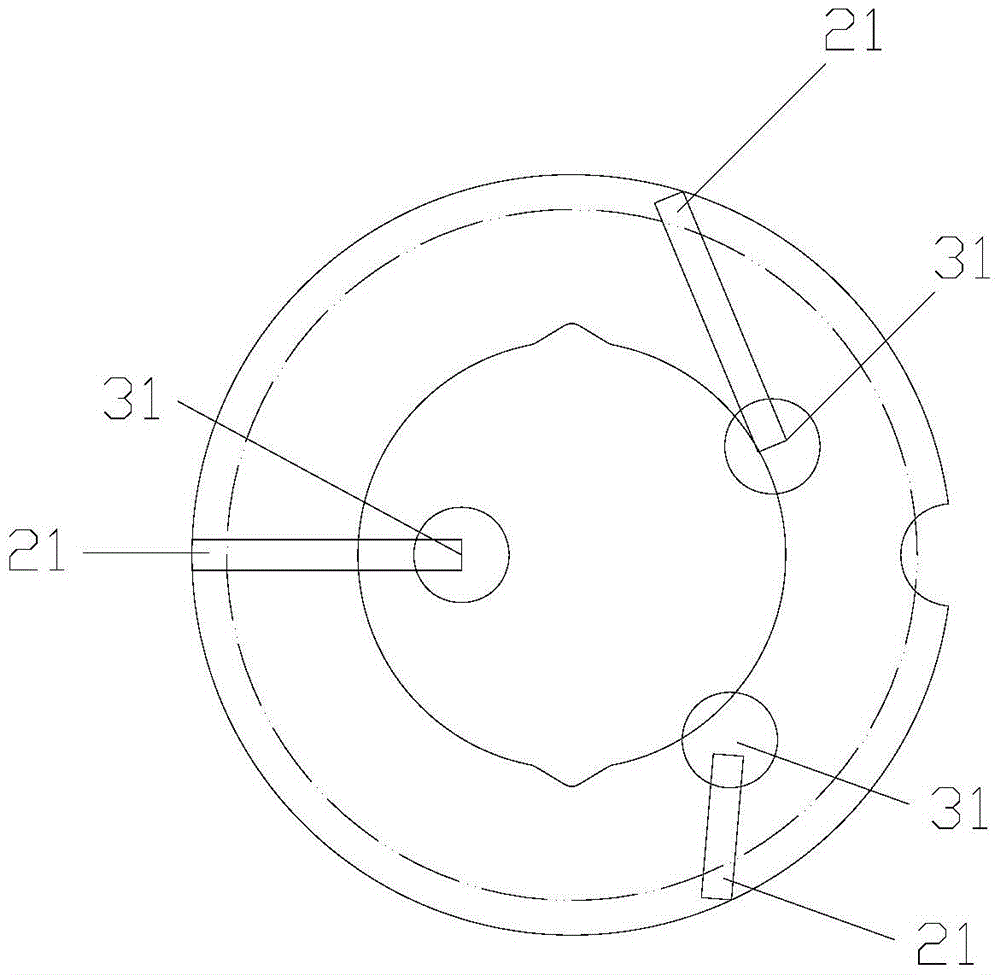

[0028] A number of horizontal support feet are set in the above-mentioned crystal boat, and at least three support feet are on the same horizontal plane at the horizontal position of each wafer in the wafer boat, and one end of each support foot is fixed on the inner wall of the wafer boat above; a support plate is provided on the end of each supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com