Demolding mechanism of plastic injection mold with convex ring cylindrical product at outer side

An injection mold and demolding mechanism technology is applied in the field of demolding mechanisms for cylindrical products with convex rings on the outside of the injection mold, and can solve the problems of inability to escape the core, the mold cannot be opened normally in sequence, and the work efficiency is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

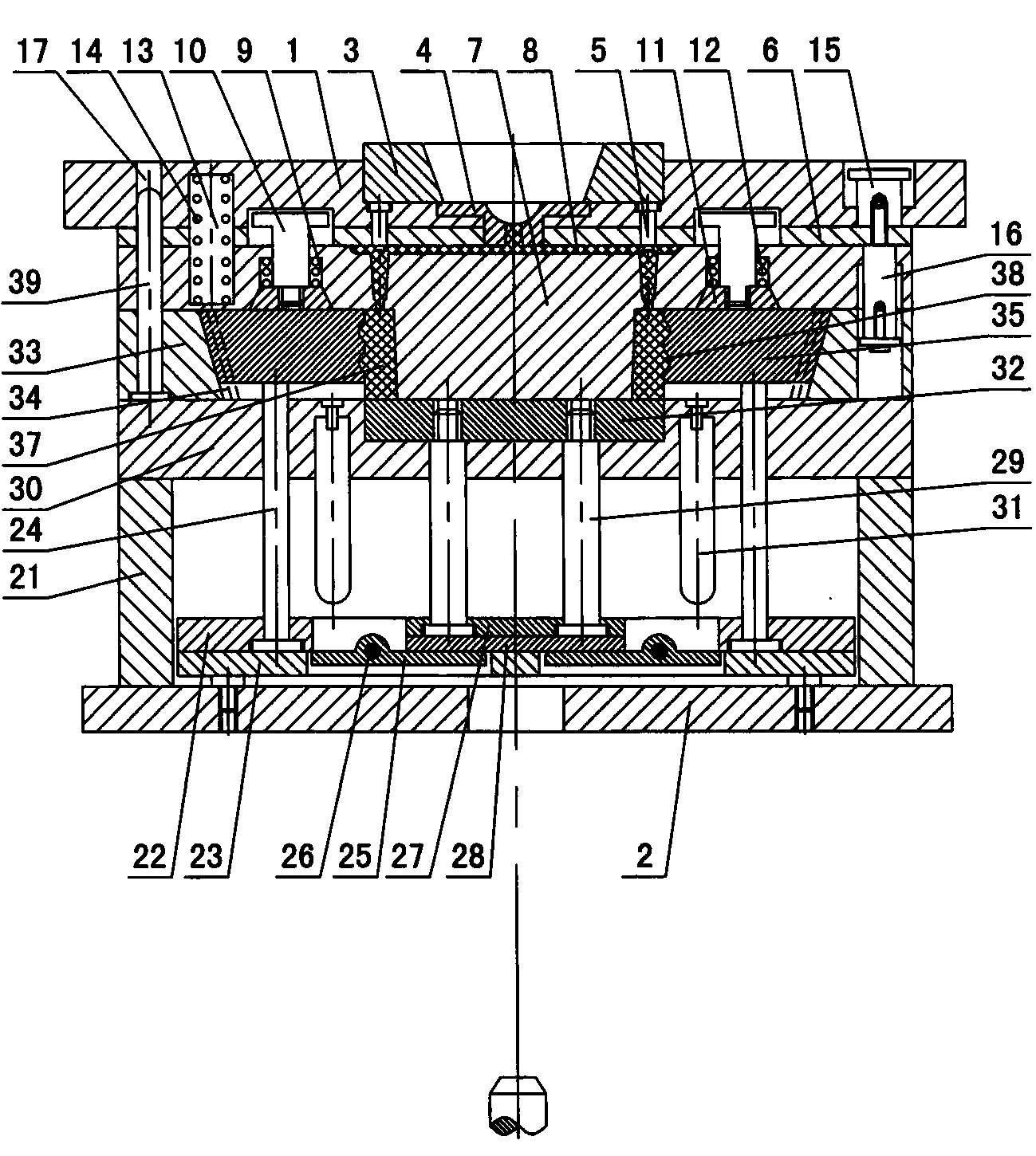

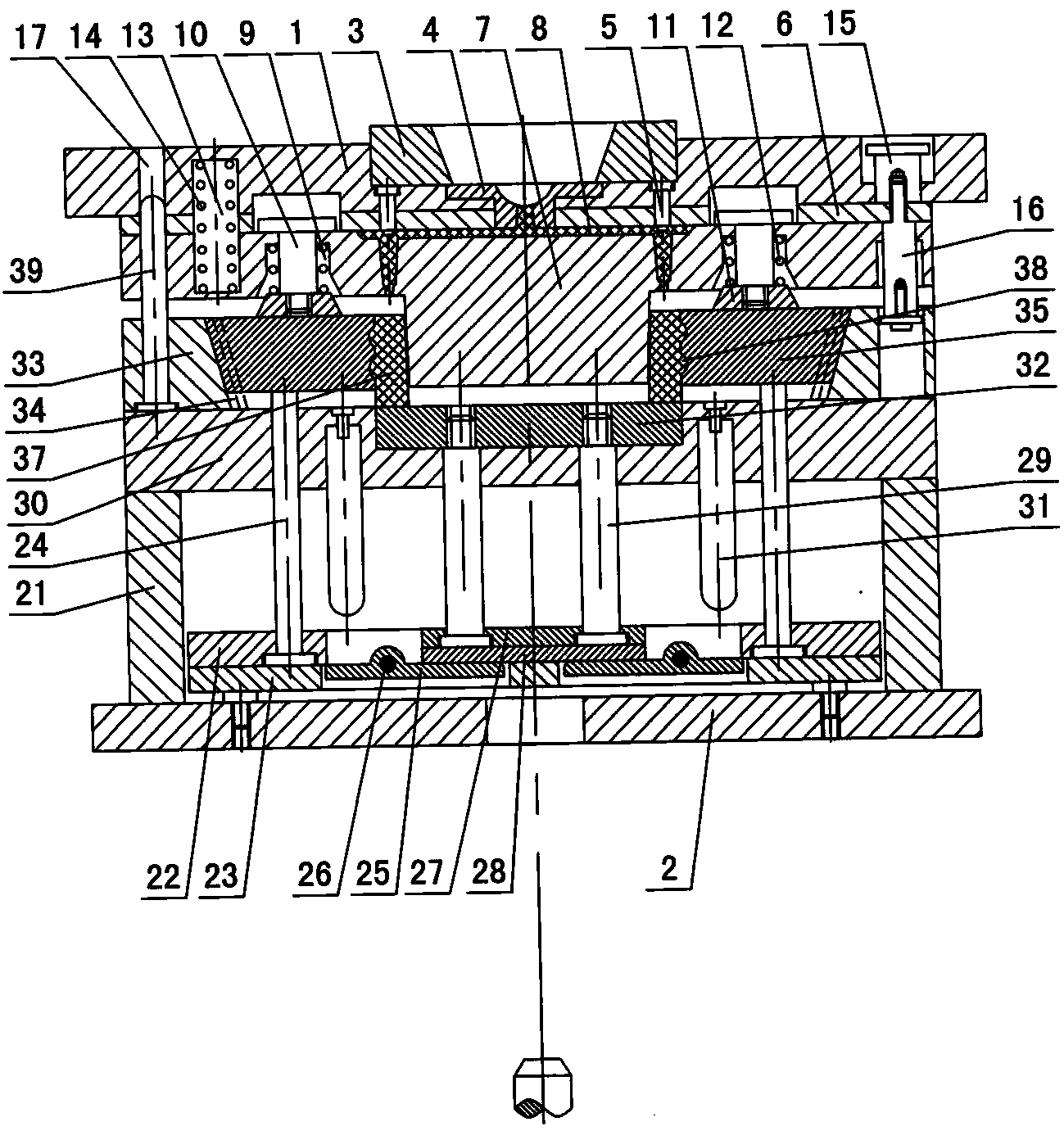

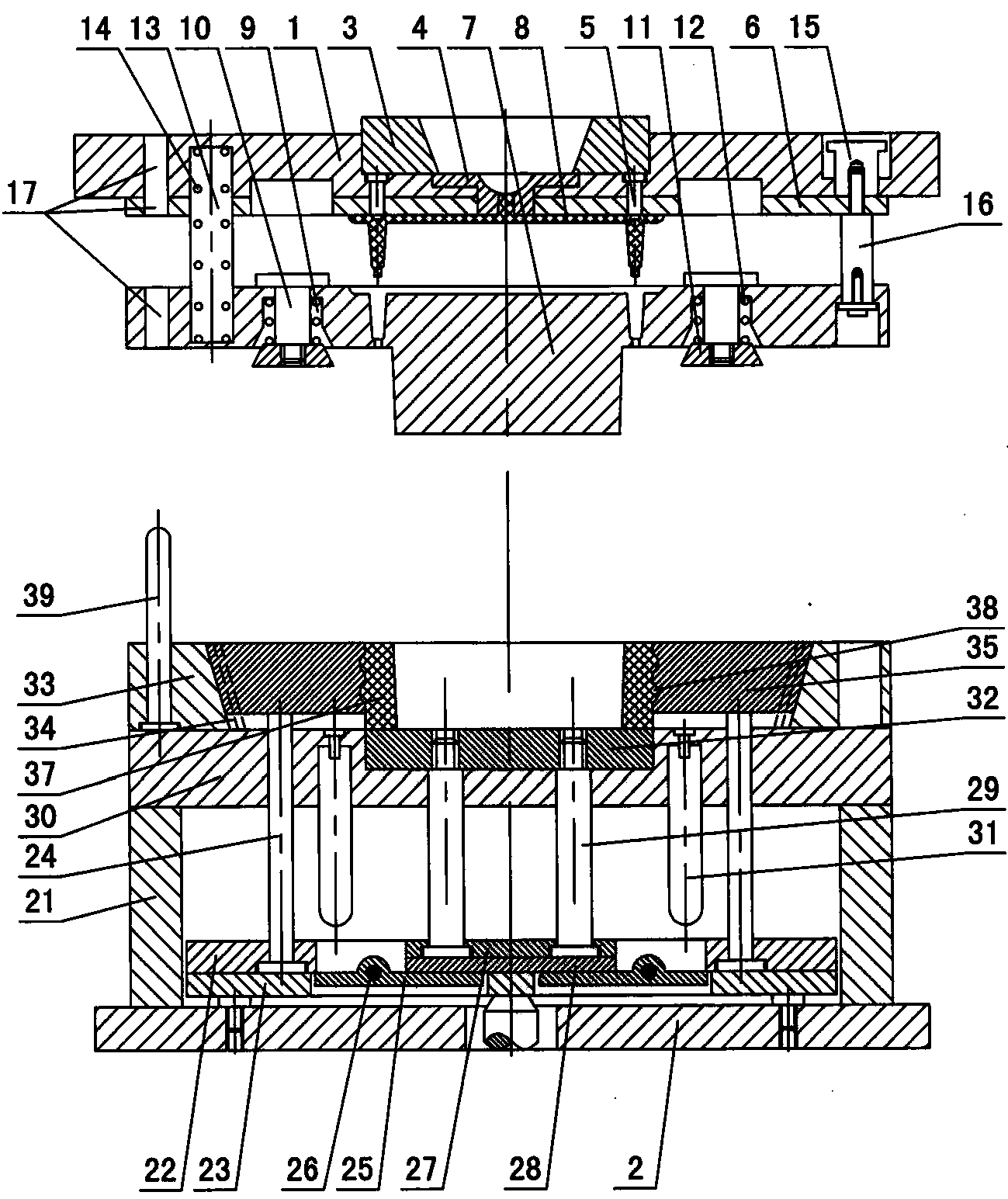

[0012] The invention relates to a demoulding mechanism for a cylindrical product with a convex ring on the outside of an injection mold, such as figure 1 — Figure 5As shown, it is characterized in that it includes an upper doubler plate 1 and a lower doubler plate 2, a positioning ring 3, a gate bushing 4 and a waste pull rod 5 are arranged in the upper doubler plate, a waste push plate 6 is arranged under the upper doubler plate, and the waste pusher A core 7 is arranged under the plate, and there is a waste material 8 between the upper end of the core and the waste material push plate. The distance screw 10, the upper part of the distance screw passes through the bullet block groove and contacts with the top of the core 7, the spring block 11 is connected under the distance screw, and the ejection spring 12 is arranged in the spring block groove on the outer wall of the distance screw to eject The spring is in contact with the upper surface of the spring block 11, and a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com