One-time forming grid eight-layer light weight wall

A light-weight wall and grid-like technology, applied to walls, building components, buildings, etc., can solve the problems of easy combustion, cumbersome construction procedures, and easy breakage and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

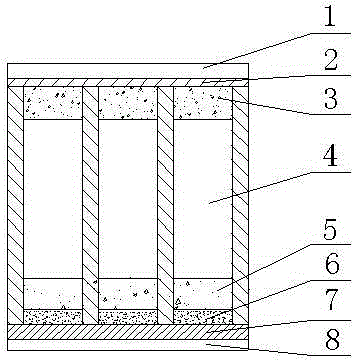

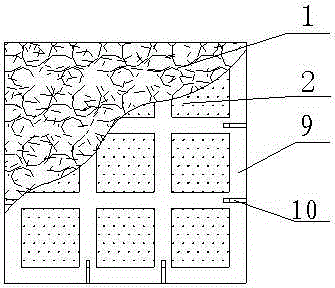

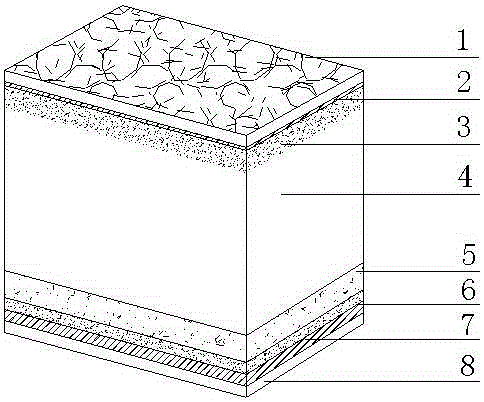

[0013] Referring to the accompanying drawings, a grid-like eight-layer lightweight wall is formed at one time, including an exterior wall surface decoration layer 1, a fiber grid layer 2, a heat-insulating and flame-retardant layer 3, a foam layer 4, a structural layer 5, a sound-insulating layer 6, and a plating layer. Zinc-steel mesh layer 7, inner wall surface layer 8, grid reinforcing ribs 9, steel embedded parts 10, an outer wall surface decoration layer 1 is set in the mold, and a fiber mesh layer 2 is set on the outer wall surface decoration layer 1, Set grid reinforcing ribs 9 on the fiber grid layer 2 in the mold, set two steel embedded parts 10 on each of the four sides of the grid reinforcing ribs 9, and set a thermal insulation and flame-retardant layer on the fiber grid layer 2 3. Set a foam layer 4 on the thermal insulation and flame-retardant layer 3, set a structural layer 5 on the foam layer 4, set a sound insulation layer 6 on the structure layer 5, and set a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com