a dust collector

A technology for collecting chips and filter cartridges, which is used in wellbore/well components, earth-moving drilling, etc. It can solve the problems of limited number of construction wells, cannot be reused, and limited service life, and achieve the effect of improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

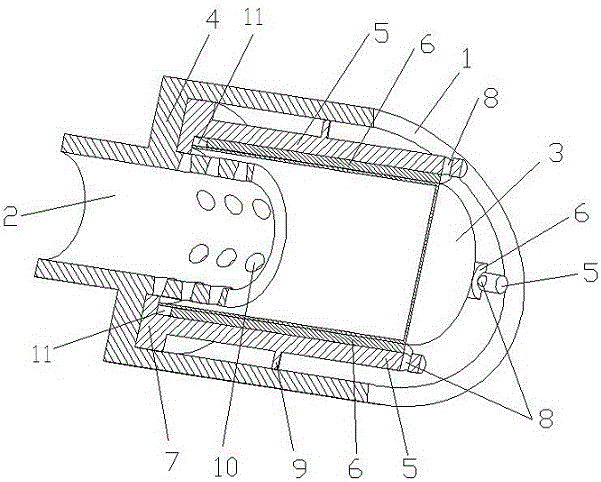

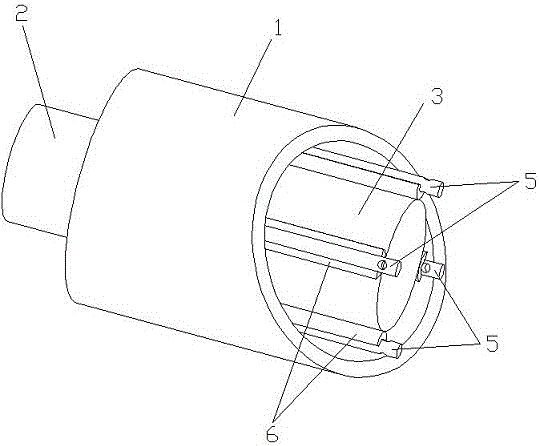

[0019] like figure 1 , figure 2 As shown, a chip collecting drum includes a filter cartridge 3, and the filter cartridge 3 is arranged in a housing 1. The housing 1 is a round pipe with an annular bottom plate 4 at one end, and the annular bottom plate 4 is penetrated with The connecting pipe 2 and the filter cartridge 3 can arrange holes according to the screening accuracy.

[0020] A plurality of guide grooves 6 are evenly distributed along the axial direction on the outer wall of the above-mentioned filter cartridge 3. The guide grooves 6 are used as the skeleton of the filter cartridge 3 to prevent the deformation of the filter cartridge 3. Guide rods 5 are arranged in the guide grooves 6, and the guide rods One end of 5 is fixed on the annular base 7, which is placed in the housing 1 and connected to the annular base 4. The annular base 4 and the annular base 7 can be connected by bolts, which is convenient for disassembly, processing and later maintenance. When instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com