10kv cable outer semiconductive layer combination cutter

An outer semi-conductive layer, 1.10kv technology, applied in the direction of dismantling/armouring cable equipment, etc., can solve the problems of rough cutting and unevenness of the cable head, to ensure the construction quality, the cutting effect is consistent, and the cutting surface is consistent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

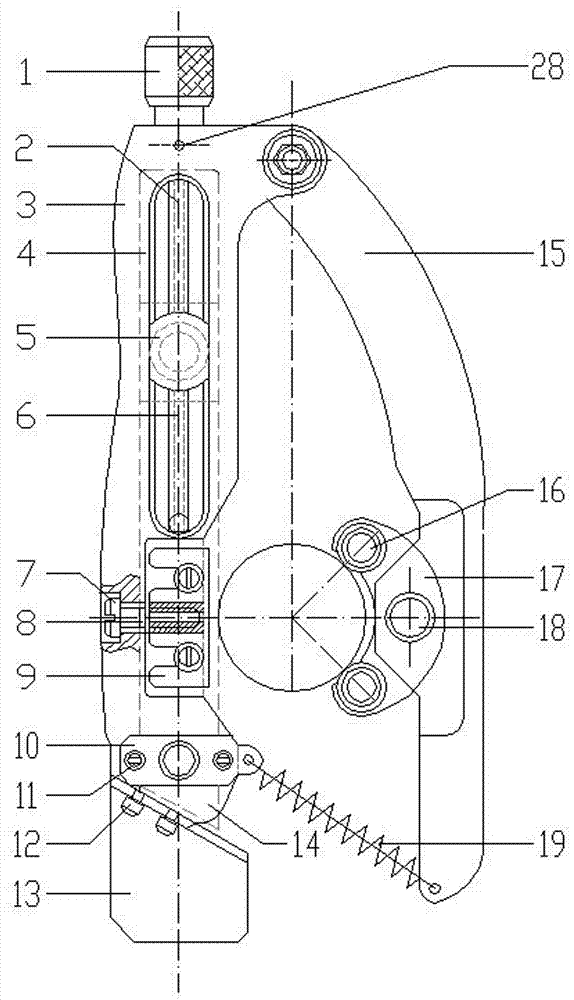

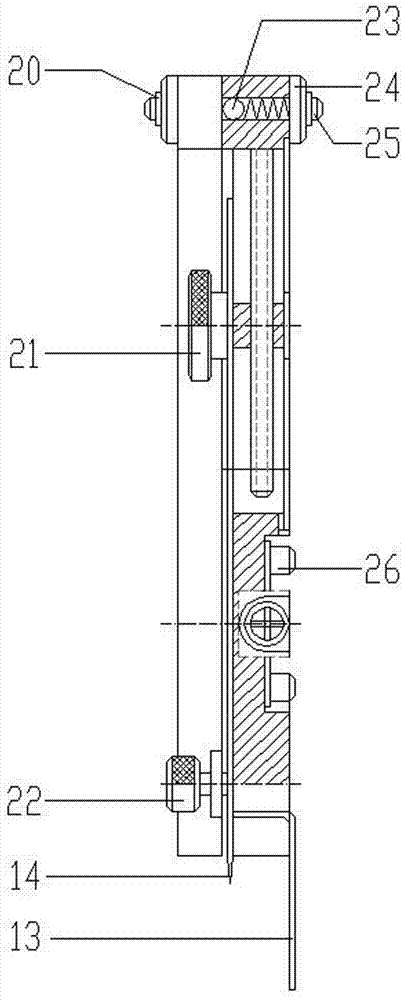

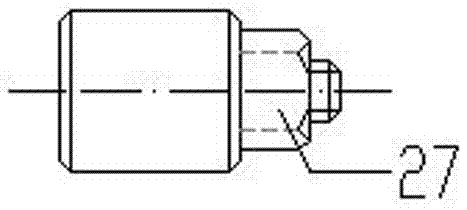

[0019] Such as figure 1 and figure 2 As shown, the 10kV cable outer semi-conductive layer combined cutter includes a main knife rest 3 and an auxiliary knife rest 15. The main knife rest 3 and the auxiliary knife rest 15 are hinged by a fixing member, and the rear end of the main knife rest 3 is provided with a feed knob 1 ; The middle part of the main knife rest 3 is provided with a guide screw chute 6 and a knife groove 4 from bottom to top in turn, and the feed knob 1 is connected with the feed screw 2 extending into the guide screw chute 6, and the feed screw 2 is A slide block 5 is provided, and a blade 14 is installed on the slide block 5, and both sides of the blade 14 extend into the knife groove 4, and the front end of the main knife rest 3 is provided with a blade pressure plate 10 through a pressure plate fixing screw 11; The main tool rest 3 in the middle is provided with a transverse feeding device; the position corresponding to the auxiliary tool rest 15 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com