Method for attaching reinforcing steel sheet to flexible circuit board and steel sheet supplementing device adopted in the method

A technology of flexible circuit boards and reinforcing steel sheets, which is applied to printed circuits, printed circuit manufacturing, and printed circuit assembly of electrical components, and can solve problems such as low automation, manual weaving of material strips, and time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

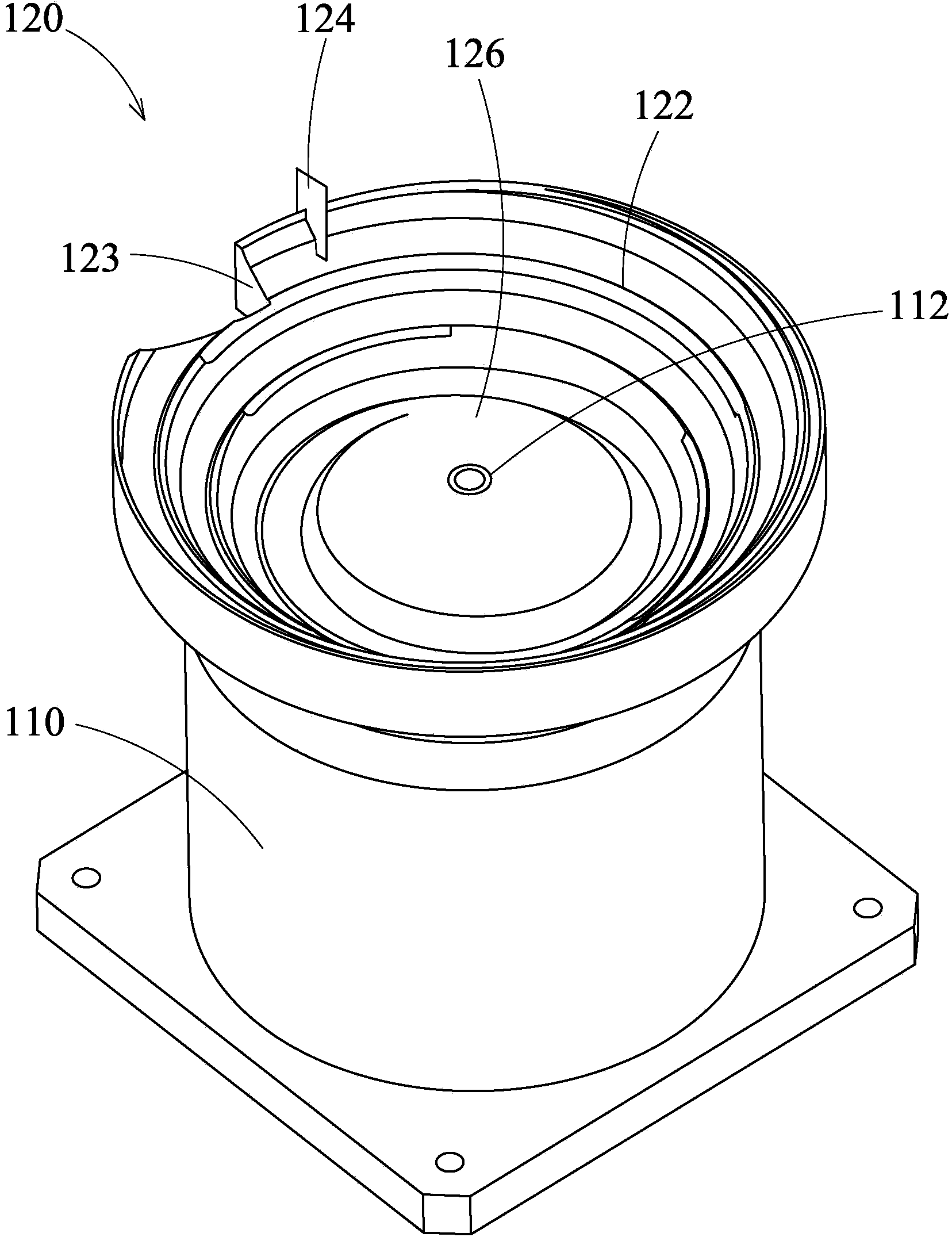

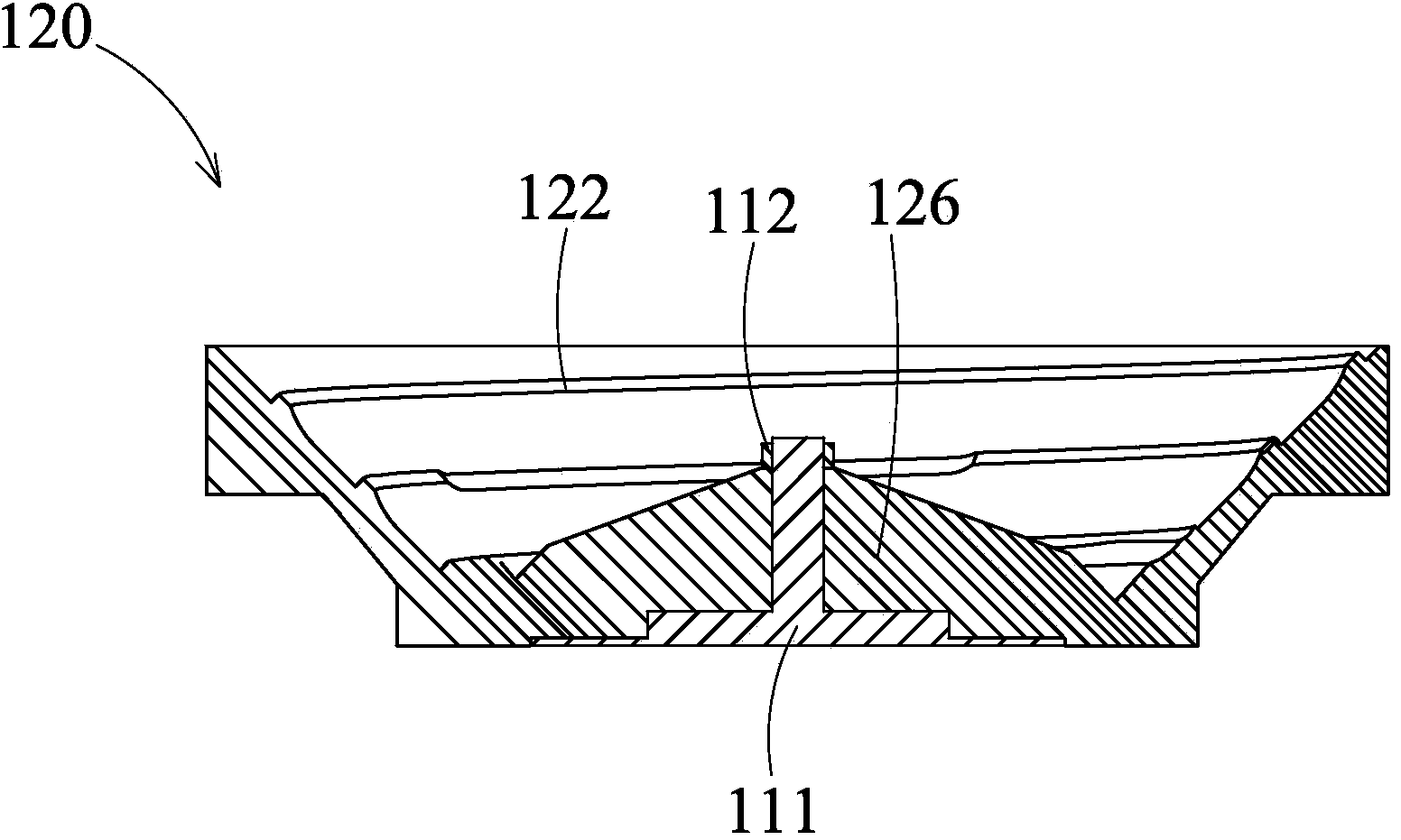

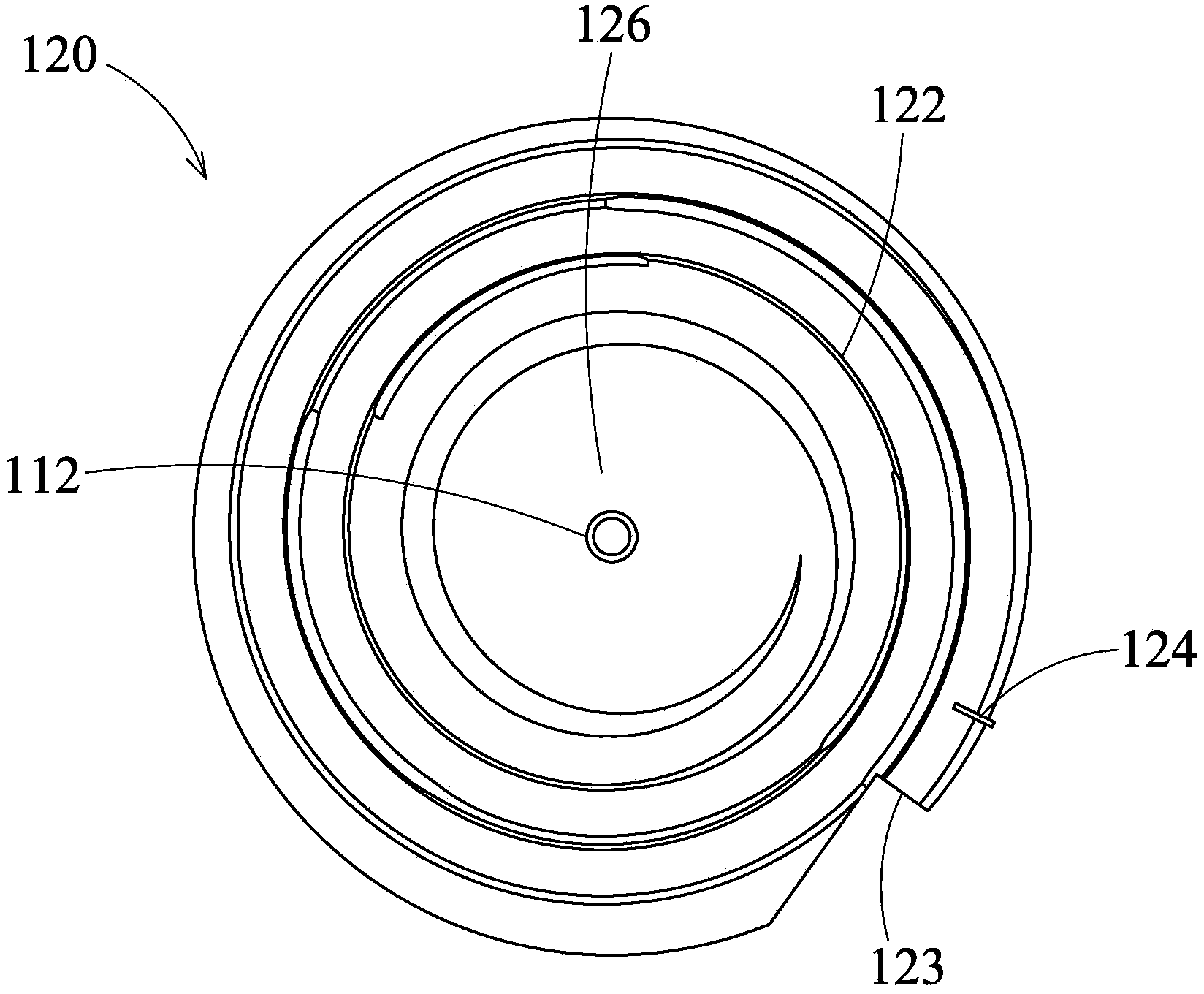

[0036] The steel sheet replenishing device of the present invention includes a steel sheet circulation screening device for screening the reinforcing steel sheet 304 and a steel sheet linear conveying device for transporting the screened reinforcing steel sheet 304 to the suction nozzle 501 of the SMT placement machine , the reinforcing steel sheet 304 is rectangular.

[0037] figure 1 Shows a perspective view of the steel sheet circular screening device, which includes a vibrating plate 120 and a piezoelectric circular vibration vibrator connected to the bottom of the vibrating plate 120 and capable of causing the vibrating plate 120 to generate reciprocating torsional vibrations , in this embodiment, the piezoelectric circular vibration vibrator is preferably the piezoelectric circular vibration vibrator produced by Dalian Hengli Automation Equipment Co., Ltd., the model is HY-JI20, and its input parameter is AC250 / 400Hz, the vibration The frequency is 180~240Hz. Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com