A device that can automatically adjust the preheating position of the cutting gun

An automatic adjustment and cutting torch technology, applied in the field of continuous casting flame cutting machine equipment, can solve the problems of unguaranteed operator safety, difficult adjustment, high work intensity, etc., and achieve remote automatic adjustment of the original position of the cutting torch Convenient cutting gun in-situ effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

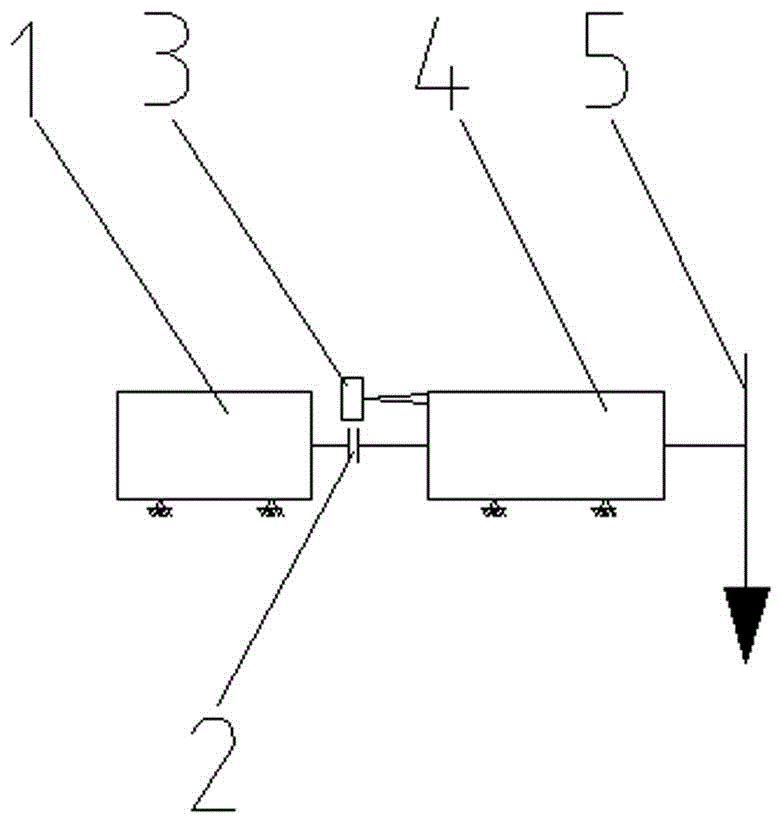

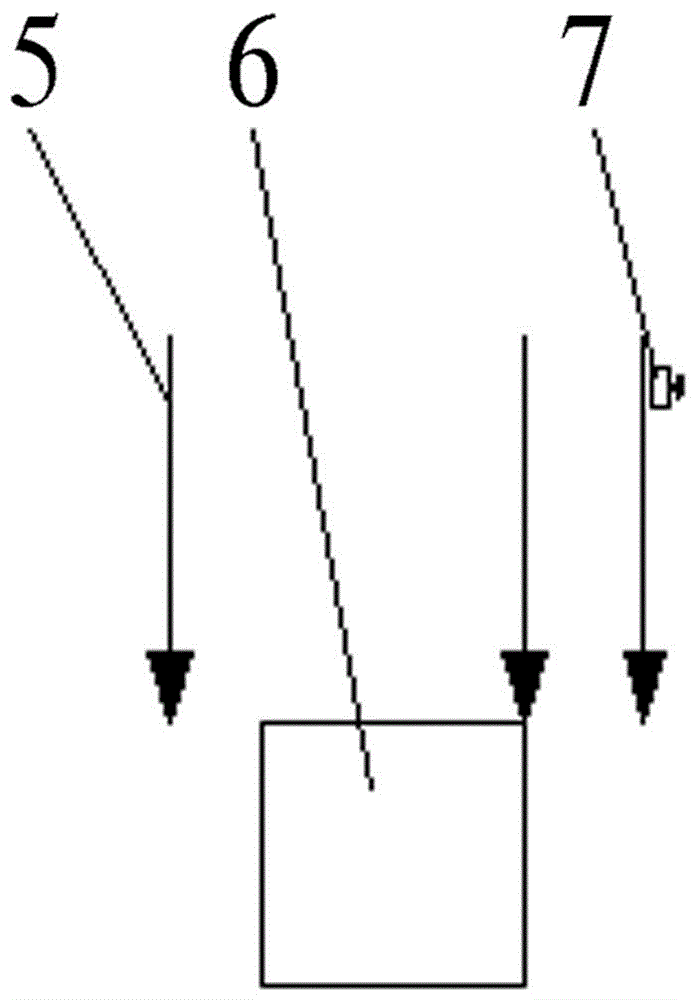

[0012] see figure 1 , a device that can automatically adjust the preheating position of the cutting torch, including a motor 1, a stopper 2 is installed on the output shaft of the motor 1, a counting proximity switch 3 is installed on the reducer, and the other end of the output shaft is connected with the reducer 4, see figure 2 It is required that the installation position of the original cutting torch in-situ proximity switch 7 should be moved to the opposite position of the cutting direction, and there is a distance x from the edge of the billet 6 that needs to be cut, and the whole device is controlled by the PLC controller.

[0013] The design method of the above-mentioned device that can automatically adjust the preheating position of the cutting torch is: see figure 1 , when the motor 1 rotates a circle, the PLC controller judges the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com