Large-diameter pipeline transport cart

A technology for large-diameter pipelines and transport vehicles, which is applied in the fields of electric power construction and construction to achieve the effect of improving construction safety and operability, avoiding horizontal torque problems and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

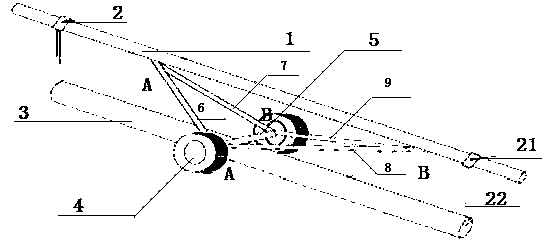

[0026] like figure 1 As shown, a large-diameter pipeline transport vehicle is composed of the following components:

[0027] ——The support rod 1, the two ends of the support rod 1 are provided with clamping fixtures 2, and the clamping fixtures 2 fixedly connect the pipe 3 and the support rod 1 into a moving whole;

[0028] - wheel set 4, said wheel set is composed of a pair of rollers arranged in pairs, the axes of said two rollers are respectively fixed at the two ends of a rotating shaft 5;

[0029] ——Fixed support frame group, described fixed support frame group is made up of the first connecting rod 6, the second connecting rod 7, the third connecting rod 8, the fourth connecting rod 9, the two ends of the first connecting rod 6 respectively fixed on the A end of the rotating shaft and the support rod A point, the two ends of the second connecting rod 7 are respectively fixed on the B end of the rotating shaft and the supporting rod A point, and the two ends of the third...

Embodiment 2

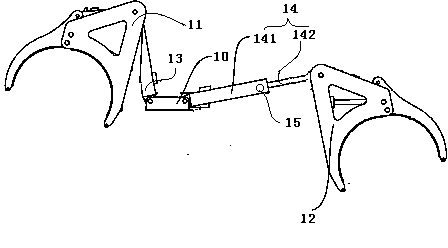

[0033] On the basis of the structure of Embodiment 1, we specifically disclose a more stable way of clamping the fixture, such as figure 2 As shown in , it consists of a connection base 10, a first handle 11 fixed to the connection base 10, and a second handle 12, and the first handle 11 and the second handle 12 are respectively fixed by respective connecting rods. In the connecting seat 10, the connecting rod is a sleeve-type structure, and the inner and outer sleeves can slide relative to each other. There is a hole at the top of the outer sleeve, and a locking screw is also included. The hole diameter at the top of the cylinder matches. exist figure 2 , we can see that for the first gripper 11, the connecting rod is 13, at this time the outer sleeve and the inner sleeve are completely overlapped together, and for the second gripper 12, the connecting rod is 14 , at this moment, the outer sleeve 141 and the inner sleeve 142 are in a state of partially sliding out, and th...

Embodiment 3

[0038] On the basis of embodiment 1 or embodiment 2, especially embodiment 2, a pick rod is further included, and the pick rod is grasped by the first gripper 11 or the second gripper 12 to form a horizontal rod body.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com