Stirring shaft upper end gas supply cutting device

A technology of cutting device and stirring shaft, which is applied to mixers with rotating stirring devices, accessories of mixers, transportation and packaging, etc. Simple, meet the needs of use, reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

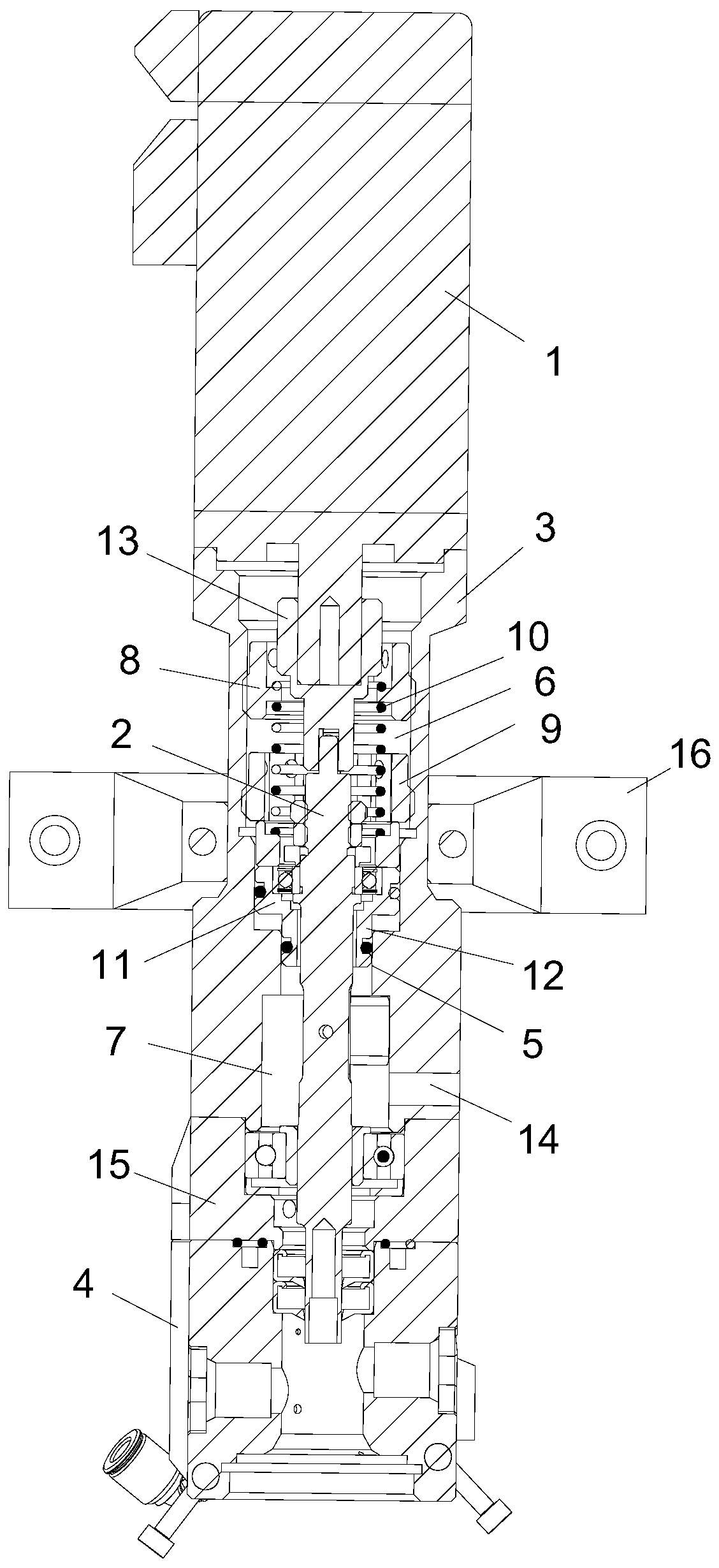

[0014] Such as figure 1 As shown, a gas supply cut-off device at the upper end of the stirring shaft 2 includes a motor 1, a stirring shaft 2, a guide seat 3 and a base 4, the guide seat 3 is hollow, and a step 5 is provided inside the guide seat 3 to divide its interior into an upper guide Cavity 6 and lower air chamber 7, the spring strength adjustment seat 8, the gap adjustment seat 9, the return spring 10 and the bearing positioning seat 11 are installed in the guide chamber sequentially from top to bottom, the spring strength adjustment seat 8, the gap adjustment The outer peripheral surface of the seat 9 is threadedly connected with the inner peripheral surface of the guide cavity. There is a bearing in the bearing locating seat 11, and the lower end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com