Tire conveying system

A conveying system and tire technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve problems such as unsafe, error-prone, and unable to keep up with the beat requirements of the main engine factory, and achieve stable and safe tire transportation, reasonable angle and length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

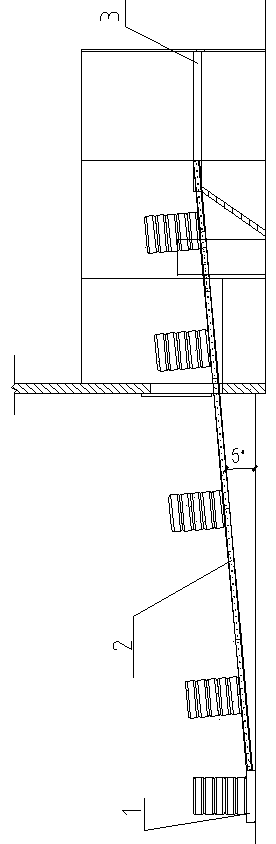

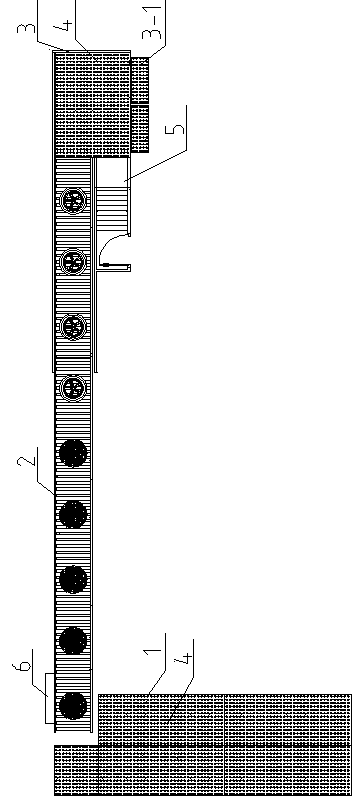

[0008] Such as figure 1 , 2 As shown, the present invention includes a first platform 1, a conveying device 2 connected to the output end of the first platform 1, a second platform 3 connected to the output end of the conveying device 2; the end of the conveying device 2 close to the first platform 1 is lower At one end close to the second platform 3, the angle between the conveying device 2 and the horizontal plane is 5°; on the top surfaces of the first platform 1 and the second platform 3, several rows of universal balls 4 are respectively distributed; the second platform 3 includes docking The turning plate 3-1 is hinged to the output end of the second platform 3;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com