Special tool and method for installing electric power circuit weight-increasing hammer

A technology of power lines and special tools, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as poor fixation, difficulty, and insufficient strength, and achieve the effects of not easy to fall off, low labor intensity, and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

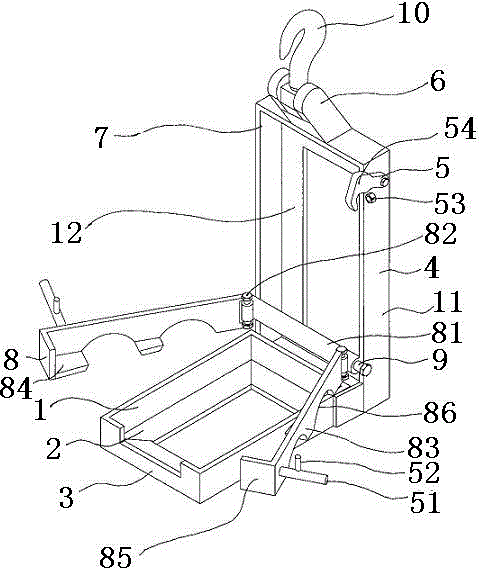

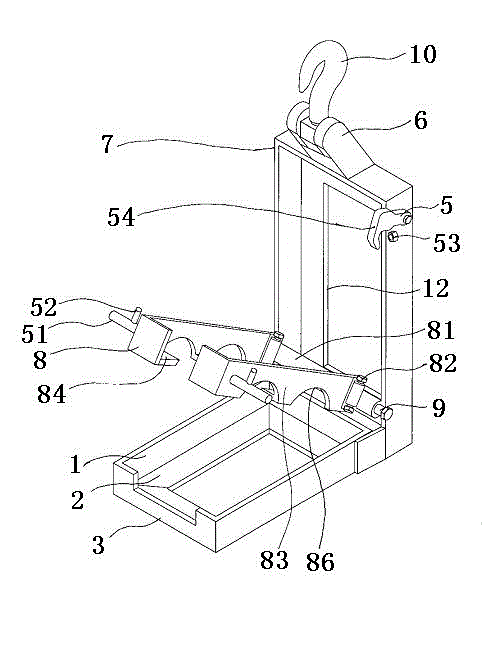

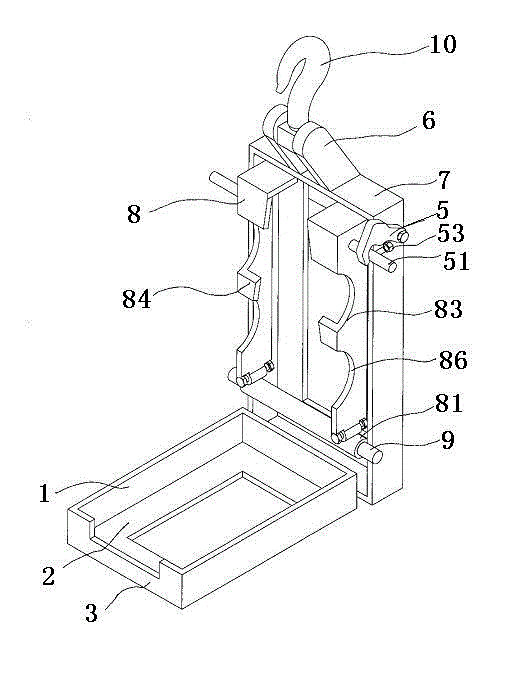

[0024] The structure of the special tool for installing the power line weight hammer proposed by the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 , figure 2 with image 3 As shown, it is a structural schematic diagram of a special tool for installing a power line weight hammer. Its structure includes a lower hammer bracket 3 with a first frame 1 and a bottom bracket 2, and an upper hammer fixing frame 4 perpendicular to the bottom bracket 2 is arranged at the rear end of the lower hammer bracket 3. The upper hammer fixing bracket 4 consists of The upper frame body 7 formed by the second frame 11 and the baffle plate 12 and the upper hammer swing frame 8 positioned at the front of the upper frame body 7 are provided with a horizontal fixed shaft 9 near the lower end of the upper frame body 7. The swing base 81 that the fixed shaft 9 rotates and the two side swing frames 83 that are connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com