Soft insulating sheath of wire

A technology of insulating sheaths and wires, applied in the field of power transmission and transformation, can solve the problems of low difficulty in installation and construction, heavy load due to false construction of wires and original insulators, increased tripping, etc., and achieve the effect of increasing insulation protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

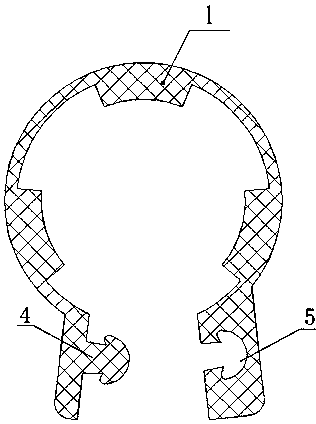

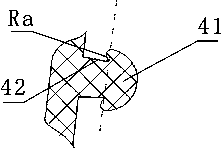

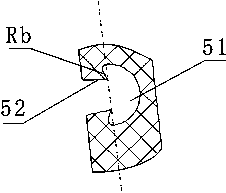

[0022] figure 1 , 2 , 3, 4, the sleeve body 1 is a hose, there are three boss ribs in the hose wall, a heat dissipation gap 3 is formed between two adjacent boss ribs, a pipe seam is arranged on the hose wall, and the hose pipe There are two connecting handles extending radially on both sides of the seam. When the two connecting handles move relative to each other until the two ends of the pipe seam fit together, the boss ribs in the inner cavity of the hose enclose a positioning space for positioning the wire. When the two connecting handles are opposite to each other When moving to the separation of the two ends of the pipe seam, the boss ribs in the inner chamber of the hose enclose an assembly space for assembling the wires, and the two connecting handles are provided with connecting parts for connecting. There is a fastener on the connecting handle, and the fastener includes a convex buckle 4 and a concave buckle 5, which are convenient to buckle in. The hook-shaped part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com