Comprehensive well mouth operating device for workover treatment

An operating device and well workover technology, applied in drilling equipment, earth-moving drilling, drill pipe and other directions, can solve the problems of harsh ground environment, high labor intensity of workers, improper personnel cooperation, etc., to prevent potential safety hazards, reduce labor intensity, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further disclose the technical solution of the present invention, the following will be described in detail through the embodiments in conjunction with the accompanying drawings:

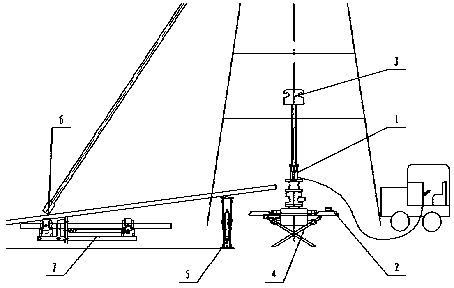

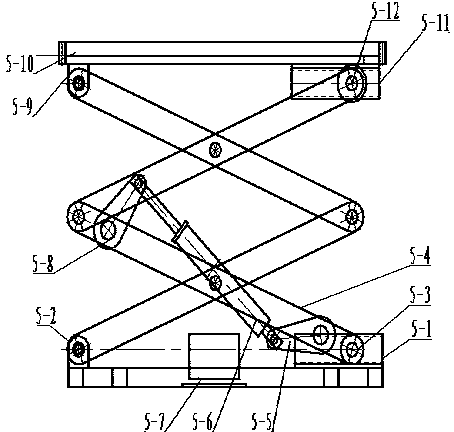

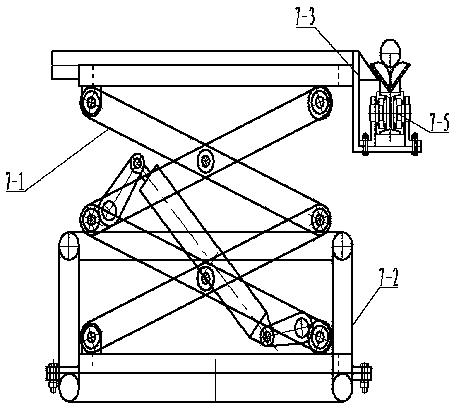

[0051] The present invention includes wellhead pneumatic slips 1, hydraulic pliers pneumatic throttle 2, special valve elevator 3, foldable wellhead operating platform 4, tubing bed hydraulic lifting tubing hydraulic conveying device 7 or tubing bed hydraulic lifting device 5 and magnetic protection wire ( figure 1 As shown), it is characterized in that: the opening of the foldable wellhead operating platform is installed on the wellhead blowout preventer toward the direction of the workover frame, a hydraulic tong pneumatic throttle is set on the foldable wellhead operating platform, and a wellhead pneumatic slip is set at the wellhead , There is a special valve elevator on the lifting or lowering tubing, and a tubing bed hydraulic lifting tubing hydraulic delivery device or a tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com