A clamping mechanism for applying conductive paste to wire clips

A technology of clamping mechanism and conductive paste, which is applied to the device and coating of the surface coating liquid, which can solve the problems of economic loss, wire clip defect, wire clip shaking, etc., to improve the quality of coating, improve the efficiency of coating, Avoid the effect of axial wobble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

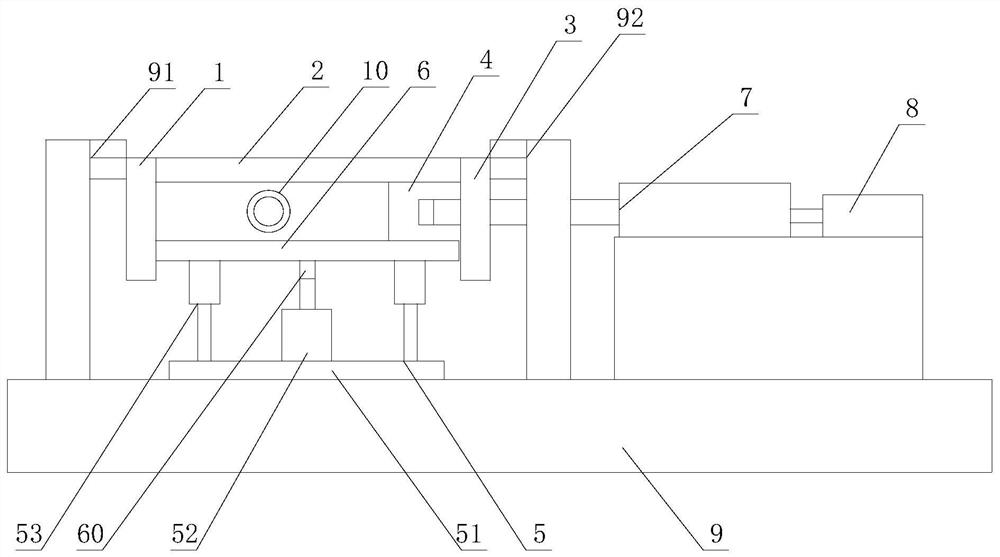

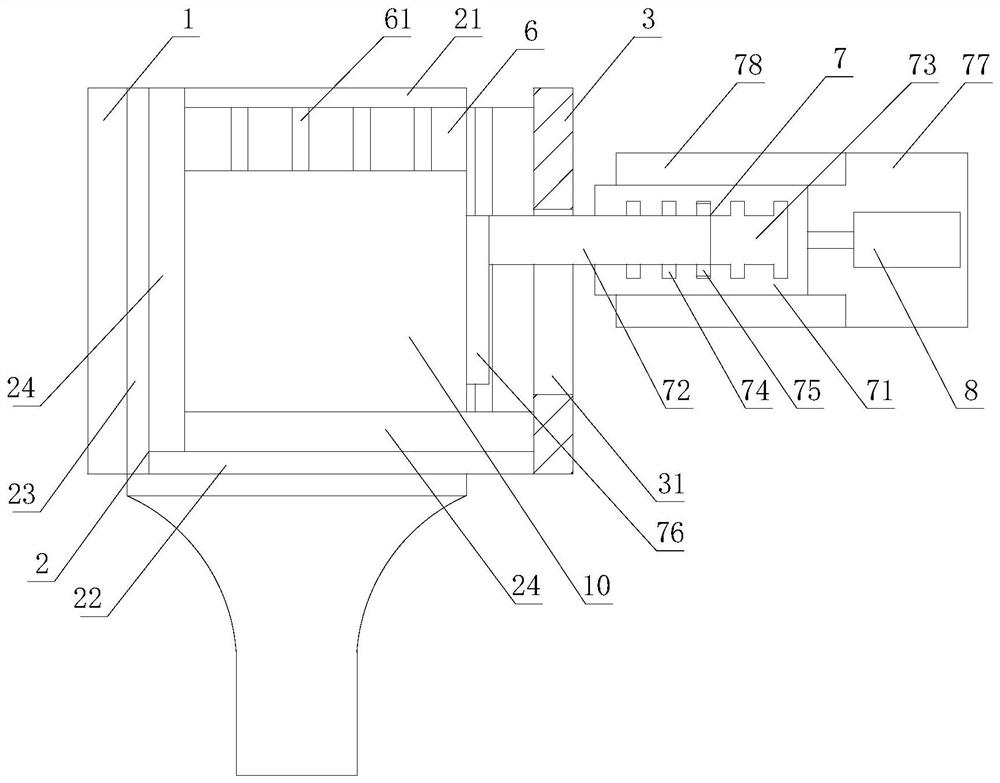

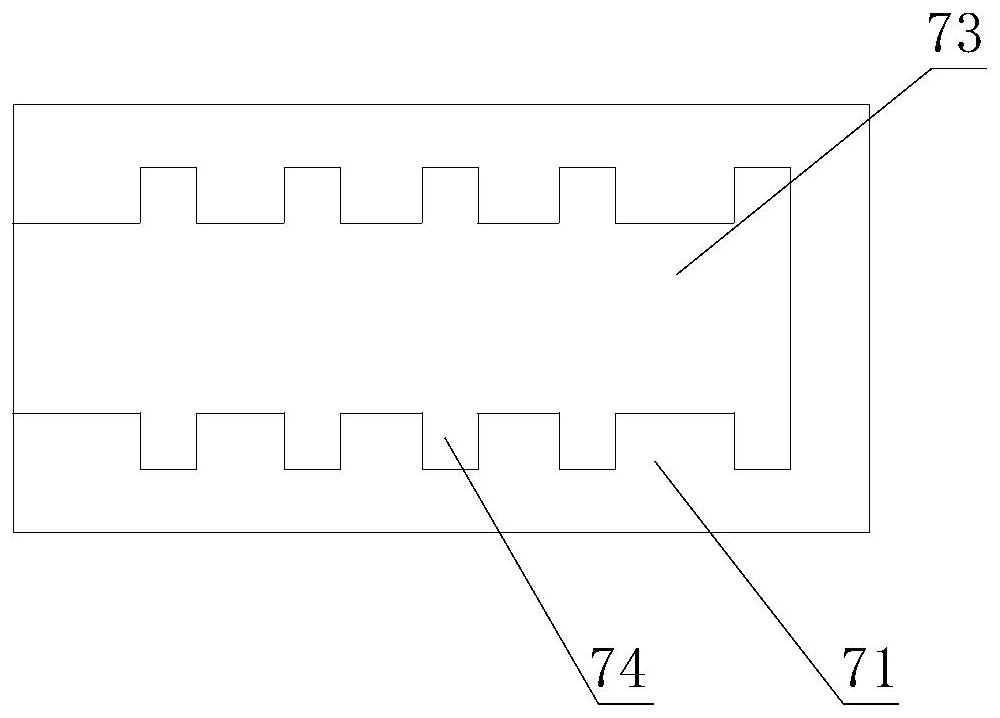

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a clamping mechanism for applying conductive paste to a wire clip includes a left baffle 1, an upper baffle 2 and a right baffle 3, and the upper baffle 2 is fixedly connected to the left baffle 1 and the right baffle 3, the left baffle 1, the upper baffle 2 and the right baffle 3 form a cavity 4 with a downward opening, and a height adjustment mechanism 5 is arranged in the cavity 4 along the height direction. The mechanism 5 includes a thrust cylinder 52 and a lower baffle plate 6 arranged on the thrust cylinder for placing the wire clip. The wire clip is fixed between the lower baffle plate 6 and the upper baffle plate 2 by means of the force of the thrust cylinder 52. The plate 1 or / and the right baffle 3 are provided with a width adjustment mechanism 7 for adjusting the width of the cavity 4. The width adjustment mechanism 7 is connected with a clamping cylinder 8 for controlling the width a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com