High-pressure high-temperature hot steam protection performance test device for fire protection equipment

A technology for fire protection equipment and protective performance, which is applied in the field of test devices for testing the thermal steam resistance performance of firefighters' protective equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

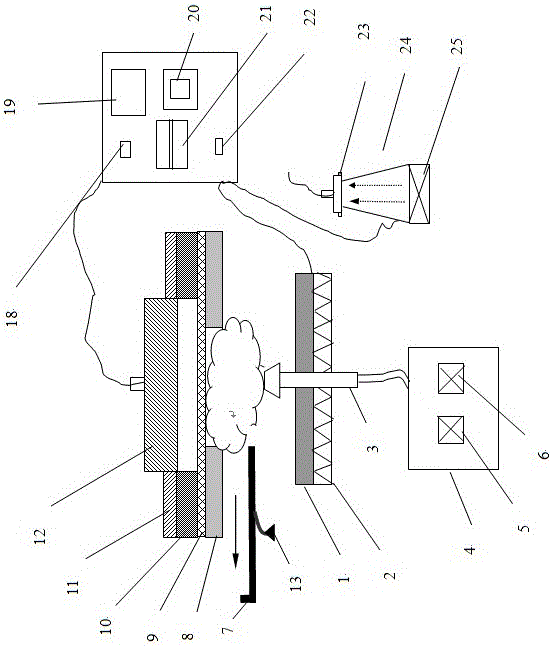

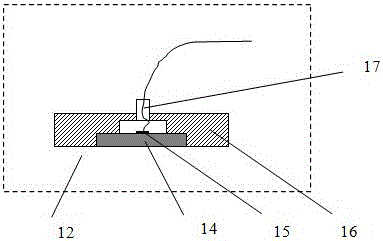

[0013] As shown in the accompanying drawings, a high-pressure high-temperature hot steam protection performance test device for fire protection equipment includes a control display system, a test system, and a heat source simulation part. The test system includes a shielding plate 7, and the shielding plate 7 is arranged on the sample support plate. 8, an air partition 10 is arranged above the sample support plate 8, a calorimeter fixing plate 11 is arranged above the air partition 10, a calorimeter 12 is arranged on the calorimeter fixing plate 11, and the calorimeter 12 is connected with the test system , A limit switch 13 is provided below the shielding plate 7 . The sample 9 is arranged between the sample support plate 8 and the air spacer 10 .

[0014] The shielding plate 7 is manually controlled, and the shielding plate 7 is twitched quickly to the left to trigger the limit switch 13, and the limit switch 13 controls the start of the experiment timing and data reading. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com