Electric wire terminal processing device

A technology for processing devices and wires, applied in circuits, electrical components, circuit/collector parts, etc., can solve problems such as wire cutting, and achieve the effect of smooth production change and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

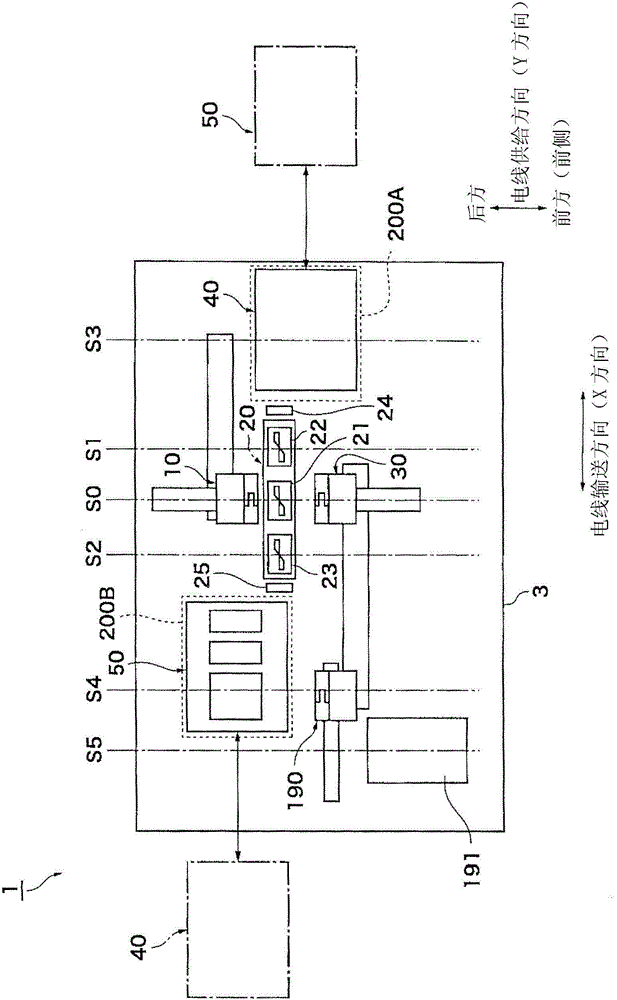

[0044] refer to figure 1 An electric wire end processing device according to an embodiment of the present invention will be described. figure 1 It is a top view schematically showing the structure of the wire end processing device. In this example, a device for crimping a terminal on one end of an electric wire and attaching solder to the other end of the electric wire will be described.

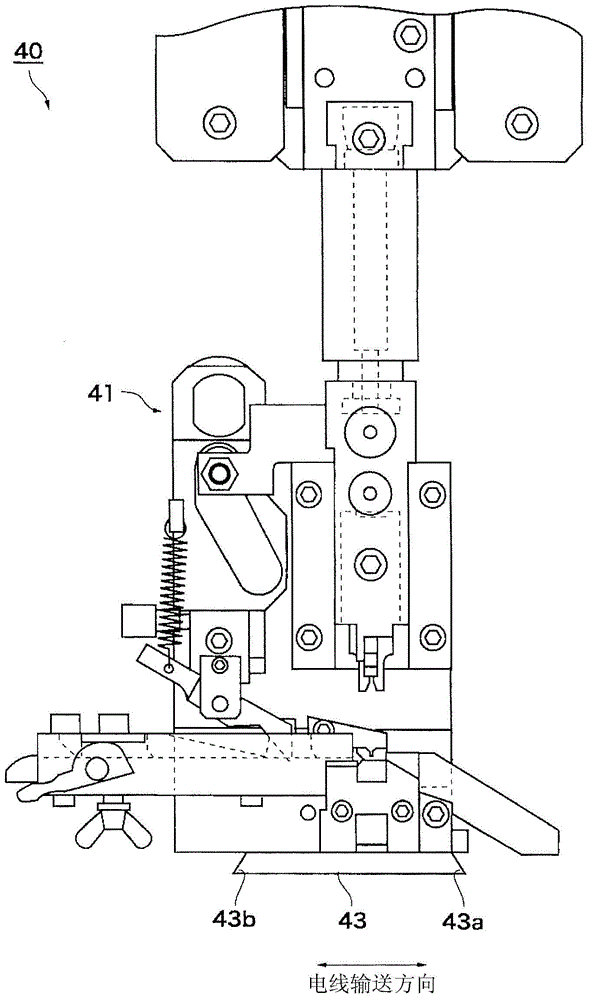

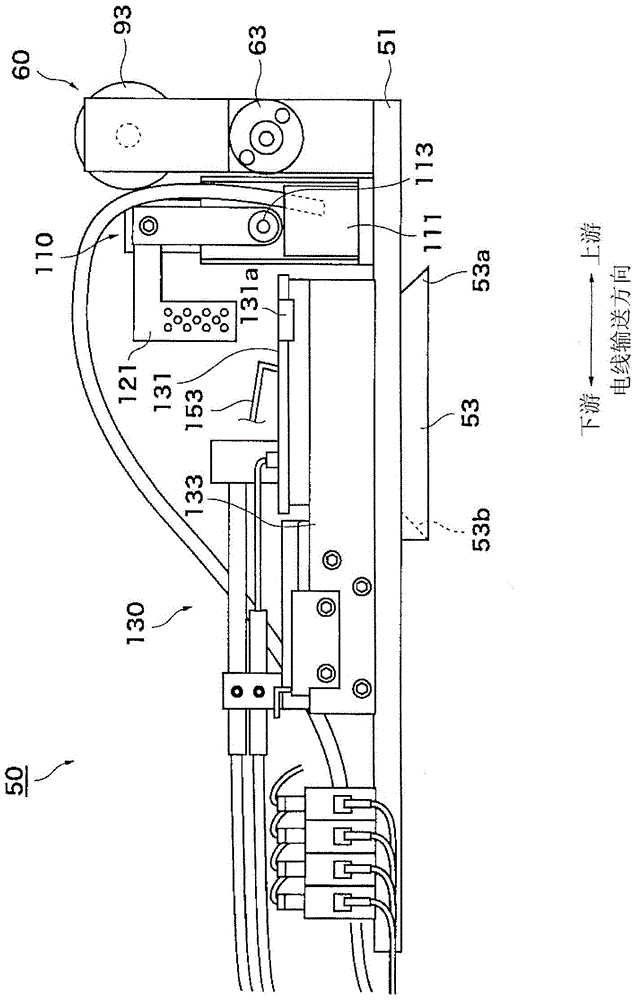

[0045] The wire end processing device 1 includes: a wire supply device 10 for supplying wires from a rolled wire bundle and clamping the wires; a cutting and stripping device 20 for cutting the wires and peeling off the sheath; clamping device 30 for clamping the end of the cut electric wire (cut electric wire); a solder attaching device 50 for attaching solder to the end of the cut electric wire clamped by the clamping device 30 ; and a delivery device 190 for delivering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com