Injection molding machine non-retention plunger injection storage cylinder structure

The technology of a storage cylinder and an injection molding machine is applied in the field of the injection structure of the plunger of the injection molding machine to achieve the effects of improving the difficulty of work, simple and reasonable structure, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

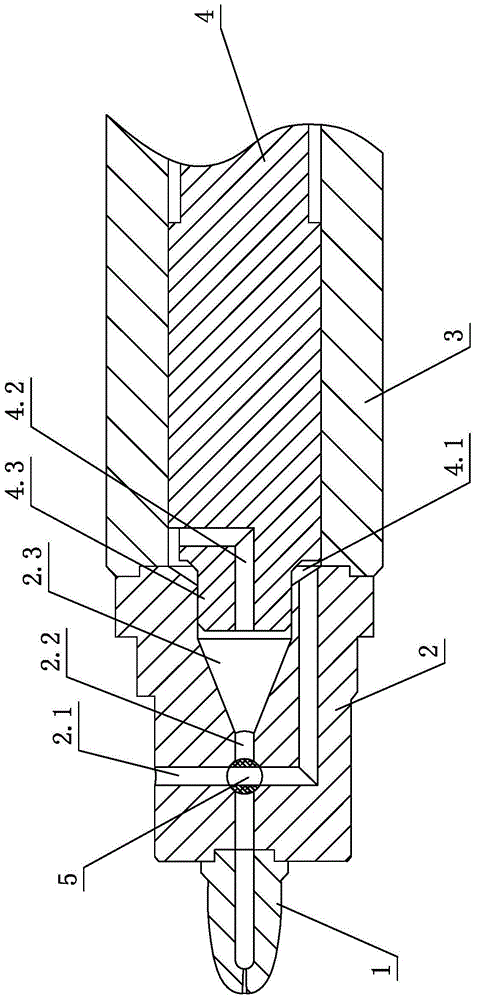

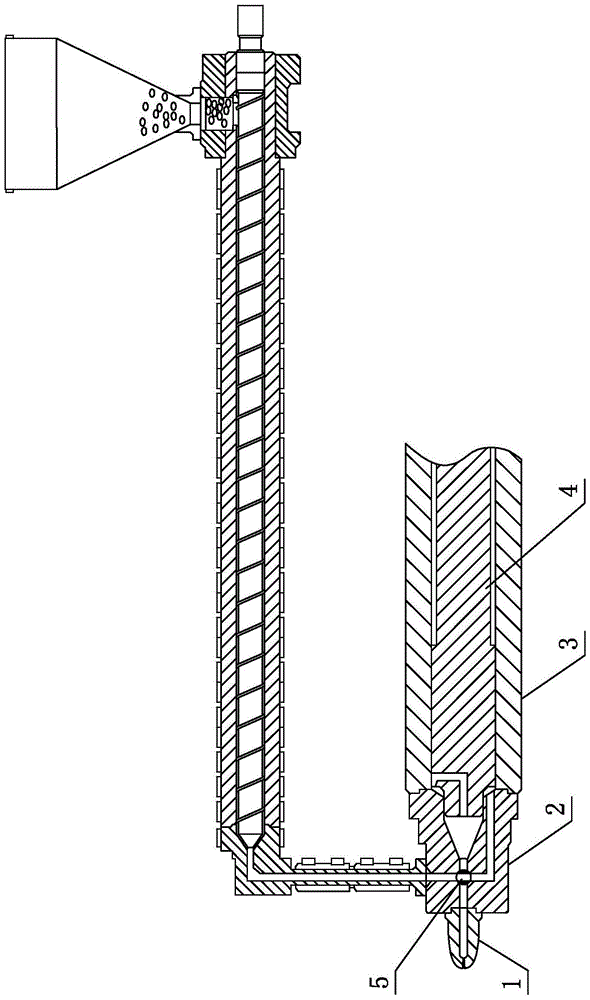

[0022] see figure 1 , the injection molding machine has no retention plunger injection storage cylinder structure, including the nozzle 1, the front flange 2 and the storage cylinder 3 which are sequentially sealed and assembled, and the plunger 4 inserted in the storage cylinder 3 which moves left and right; its characteristics In that: the front flange 2 is embedded with a shuttle valve 5; the plunger 4 is provided with a central channel 4.2; after injection, a material storage chamber 2.3 and a material storage chamber 2.3 are formed between the front flange 2 and the plunger 4 The annular material storage channel 4.1 conducts the raw material through the internal channel, and the residual rubber material is sent into the material storage chamber 2.3 to participate in the next glue injection, so as to achieve the purpose of cleaning the residual material.

[0023] Specifically, the front flange 2 is provided with a horizontal channel 2.2 and a vertical channel 2.1, which ar...

no. 2 example

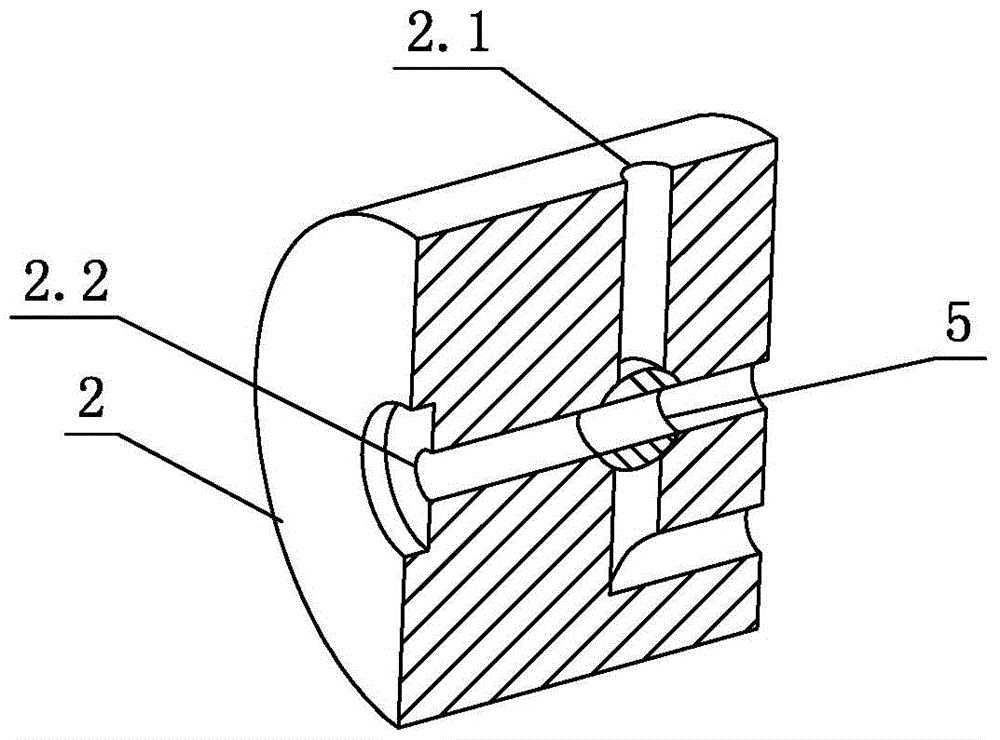

[0028] see Figure 4 , This injection molding machine has no retention plunger injection storage cylinder structure, which is different from the first embodiment in that: the shuttle valve 5 is spherical, has a passage across it, and has a rotating shaft extending outward on both sides. The front end flange 2 is a split type, and a spherical cavity and a shaft groove are correspondingly arranged at the junction, and the shuttle valve 5 is assembled together. This embodiment facilitates the repair or maintenance of the front flange 2 and the shuttle valve 5 .

[0029] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

no. 3 example

[0031] see Figure 5 , this injection molding machine has no retention plunger injection storage cylinder structure, which is different from the first embodiment in that: the vertical channel 2.1 is bent in the front flange 2, directly connected to the storage channel 4.1, and the horizontal channel 2.2 does not hand over, the shuttle valve 5 closes or opens the horizontal channel 2.2. The injection molding machine is in the material storage process, and the set program controls the rotation of the shuttle valve 5. When the passage in the shuttle valve 5 is completely separated from the horizontal passage 2.2, the horizontal passage 2.2 is closed, and the storage begins. It is helpful to prevent raw materials from overflowing from the horizontal passage 2.2 during the material storage process; at the same time, the distance of the vertical passage 2.1 is shortened, and the storage speed is fast.

[0032] Other parts not described are the same as those of the first embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com