Buffering tramcar with self-locking function

A buffer belt and self-locking technology, applied in the field of conveying machinery and equipment, can solve the problems such as easy damage to the bottom of the mine cart, inability to apply to the conveying environment with automatic static requirements, simple and simple transportation of the mine cart, etc., and achieve the effect of alleviating the crushing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

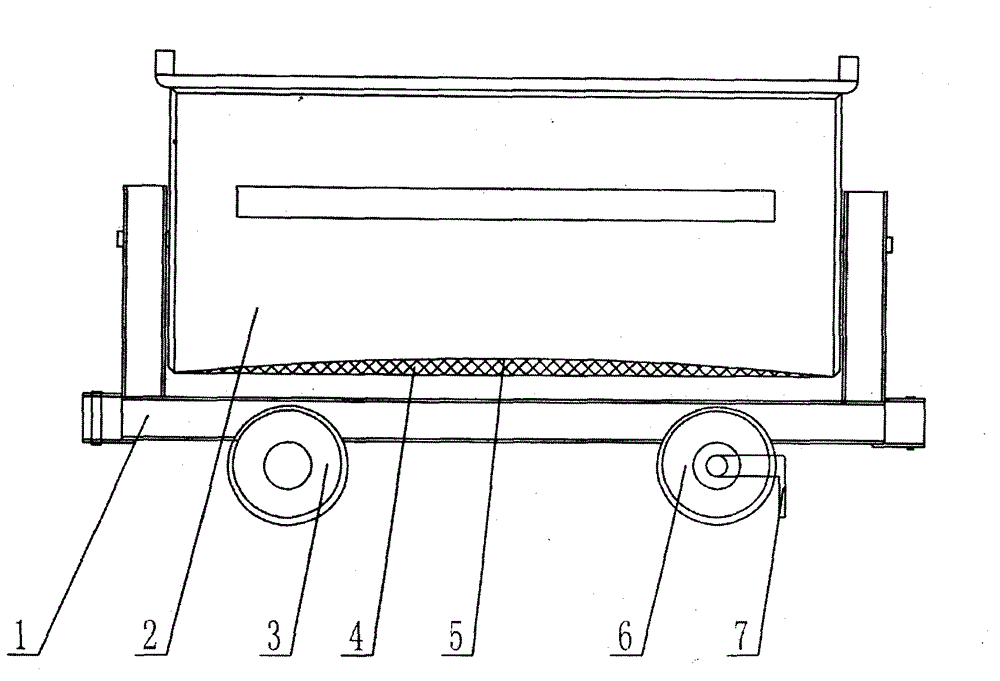

[0009] A self-locking mine car with a buffer belt is composed of a frame 1, a carriage 2, a front mine wheel 3, a rear mine wheel 6, and a brake device 7. The front mine wheel 3 is fixed on the bottom of the frame 1 through the front axle Front end, rear mine wheel 6 are fixed on the bottom rear end of vehicle frame 1 by rear axle, and braking device 7 is connected on the rear mine wheel 6 by pin shaft and bolt, and the other end surrounds on the rear axle, can shrink and open, when When the brake device is started, it is in a contracted state and locks the rear axle to play a braking effect. The compartment 2 is fixed on the upper part of the frame 1 through the connection of threaded fasteners and pin shafts, and the bottom of the compartment 2 is covered with cast rubber. 4. The middle of the buffer rubber 4 is higher than the two sides, and is bulged 5, which is normally distributed. The buffer rubber 4 can effectively buffer the crushing of the material, which can realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com