Electrophoretic paint liquid temperature control system and method

A technology of temperature control system and temperature control method, which is applied in the direction of electrophoretic plating, electrolytic coating, coating, etc., can solve problems such as failure to turn on the machine, high energy consumption, and low temperature protection of air conditioners, so as to save energy consumption and ensure the quality of electrophoresis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

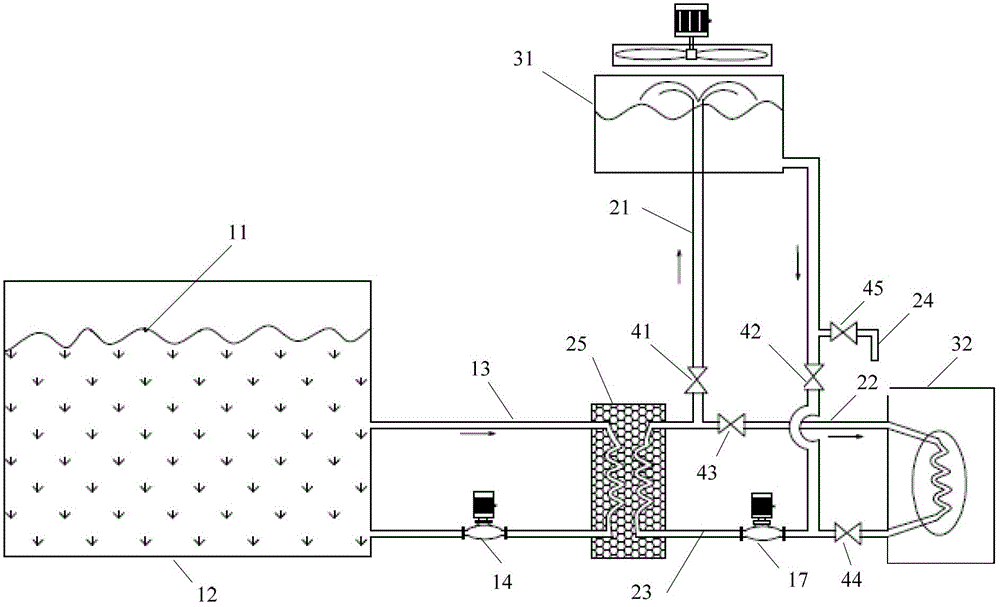

[0041] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

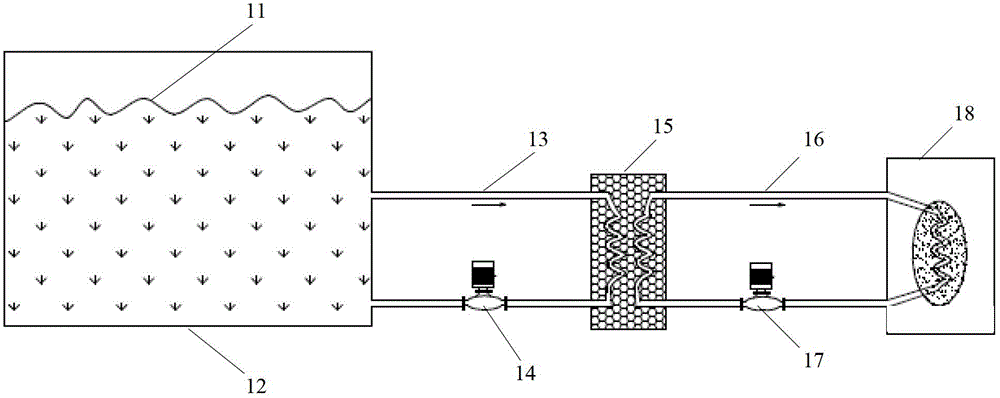

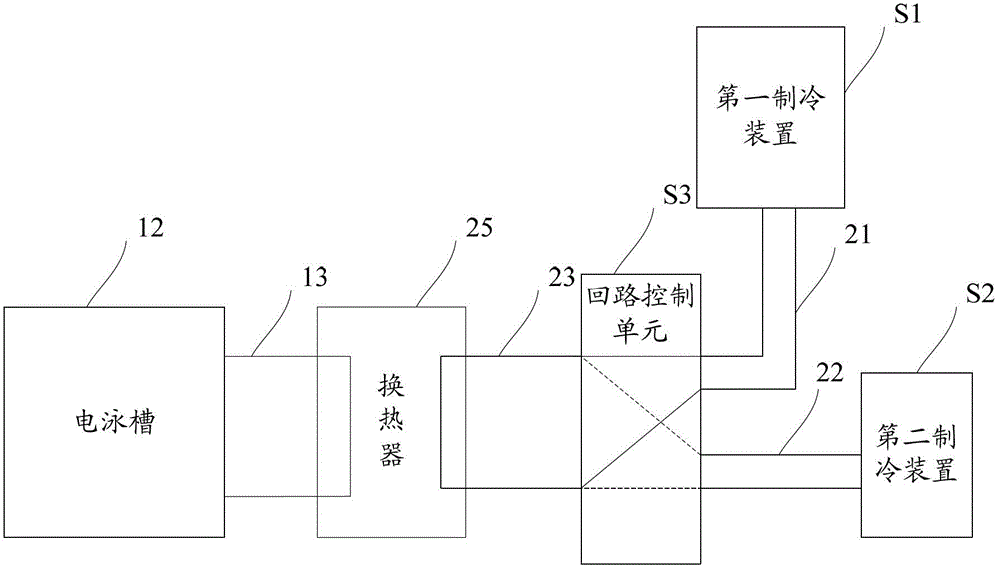

[0042] Such as figure 2 Shown is the functional block diagram of the electrophoretic paint solution temperature control system of the embodiment of the present invention.

[0043] In this embodiment, the temperature control system of the electrophoretic paint solution includes:

[0044] The heat exchanger 25, the electrophoretic paint circulation pipeline 13 connecting the electrophoresis tank 12 and the heat exchanger 25, the first refrigeration device S1, the second refrigeration device S2, and the loop control unit S3. in:

[0045] The first refrigeration device S1 is connected to the heat exchanger 25 through the first pipeline 21 and the heat exchange pipeline 23, and the second refrigeration device S2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com