Methods and systems for oxygen sensors

An oxygen sensor and sensor technology, applied in the direction of charging system, machine/engine, electrical control, etc., can solve the problems of sensor accuracy measurement and/or control reduction, confusion of sensor measurement values, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

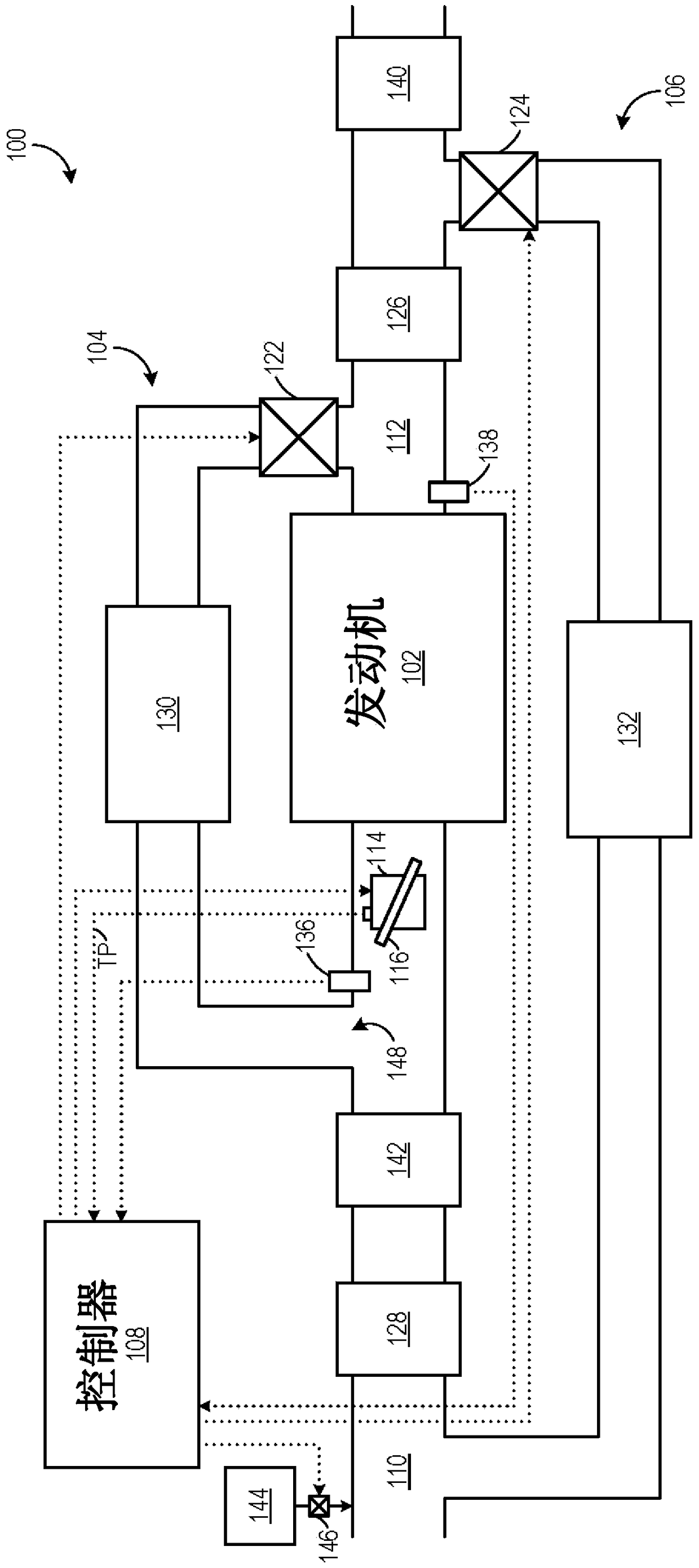

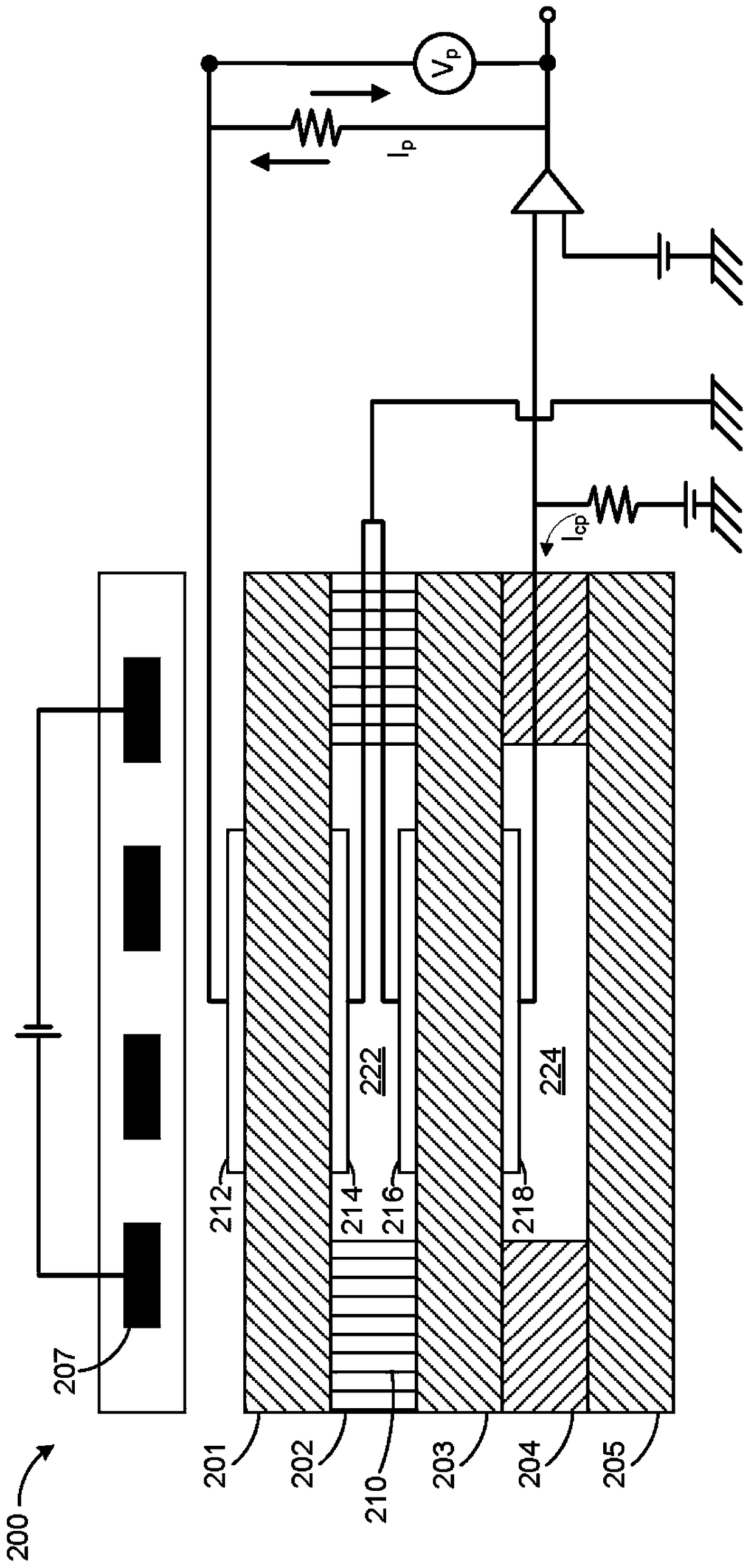

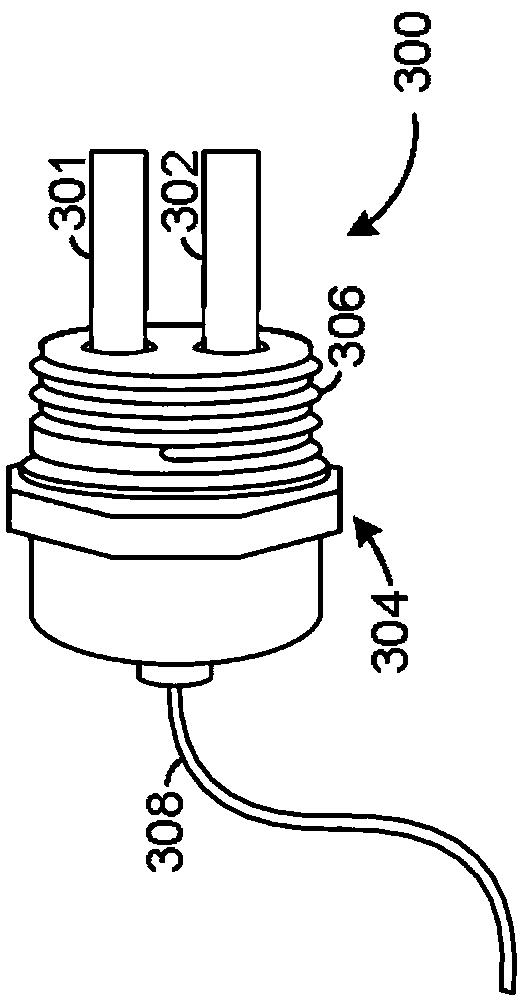

[0010] The following description relates to methods and systems for an engine system having an exhaust gas recirculation (EGR) system and catalytic and non-catalytic intake air composition sensors, such as oxygen sensors. In one example, a method includes indicating an intake oxygen concentration and a fuel vapor concentration based on an output from a catalytic sensor and an output from a non-catalytic sensor. The method further includes adjusting EGR in response to the oxygen concentration, and adjusting fuel injection and / or fuel vapor purge in response to the fuel vapor concentration. In such an example, the non-catalytic sensor output may be indicative of oxygen concentration, while the difference between the catalytic sensor output and the non-catalytic sensor output may be indicative of fuel vapor concentration. Accordingly, a measurement of EGR may be obtained that is not affected by the presence of fuel vapors in the engine intake. Accordingly, EGR may be controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com