Multi-position hole saw assembly with plug ejector

A technology for assemblies and blockages, which is applied in the direction of drilling tool accessories, tool workpiece connection, boring machine/drilling machine parts, etc., can solve problems such as difficult removal of blockages, and achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

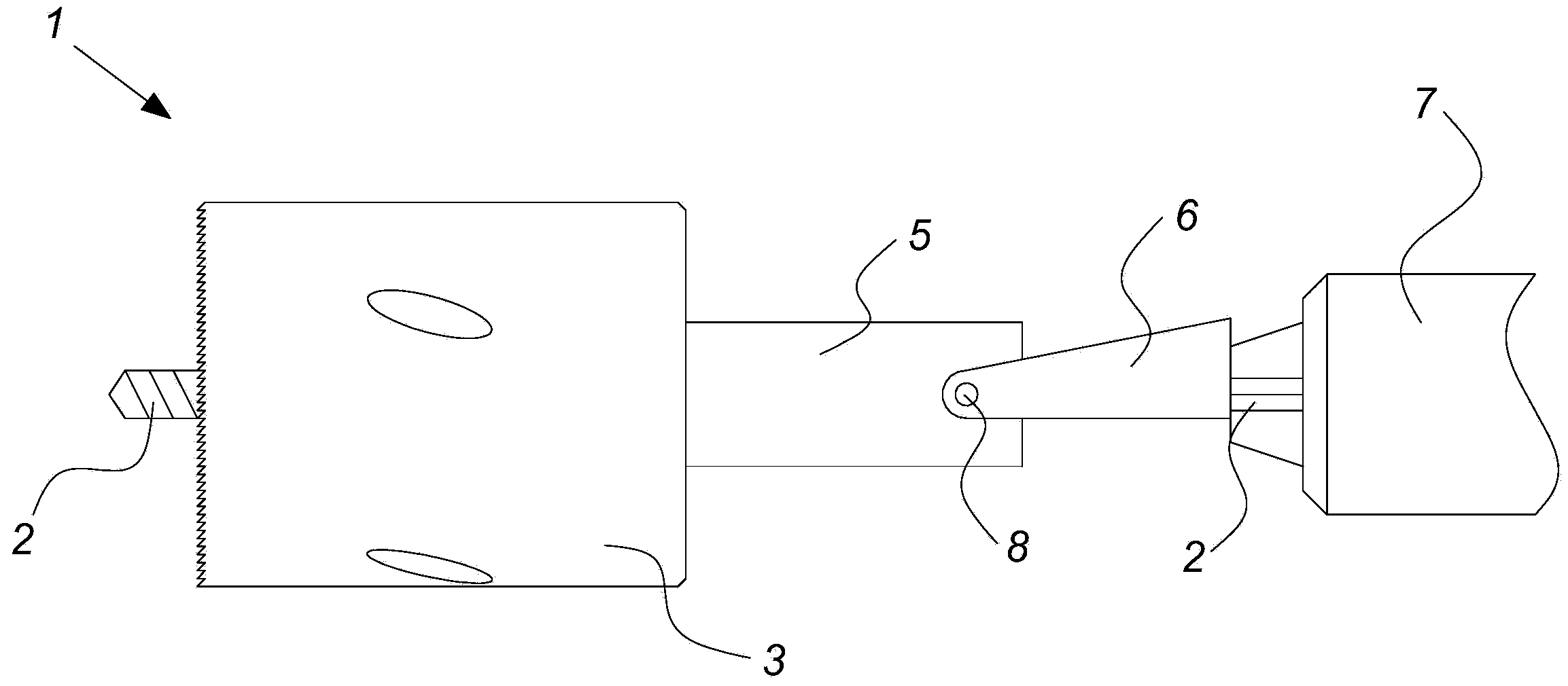

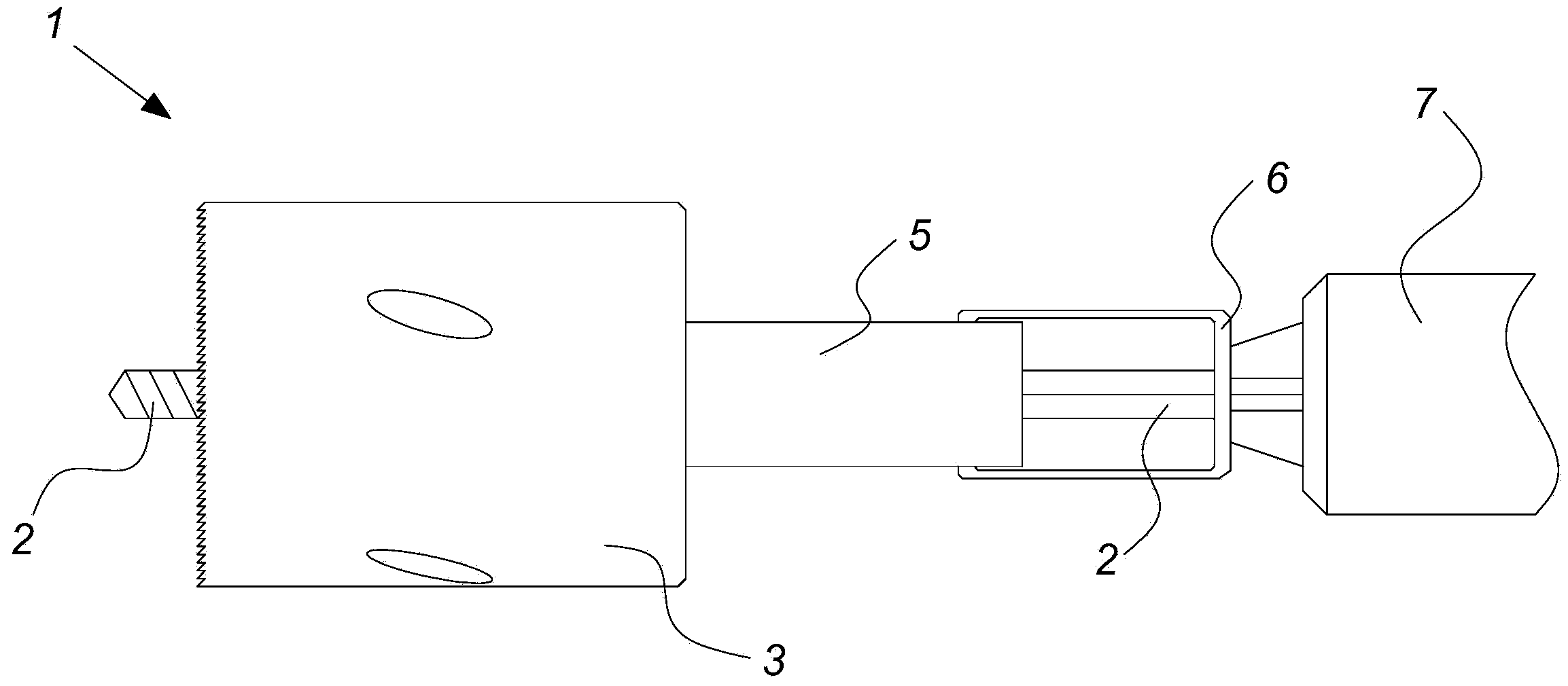

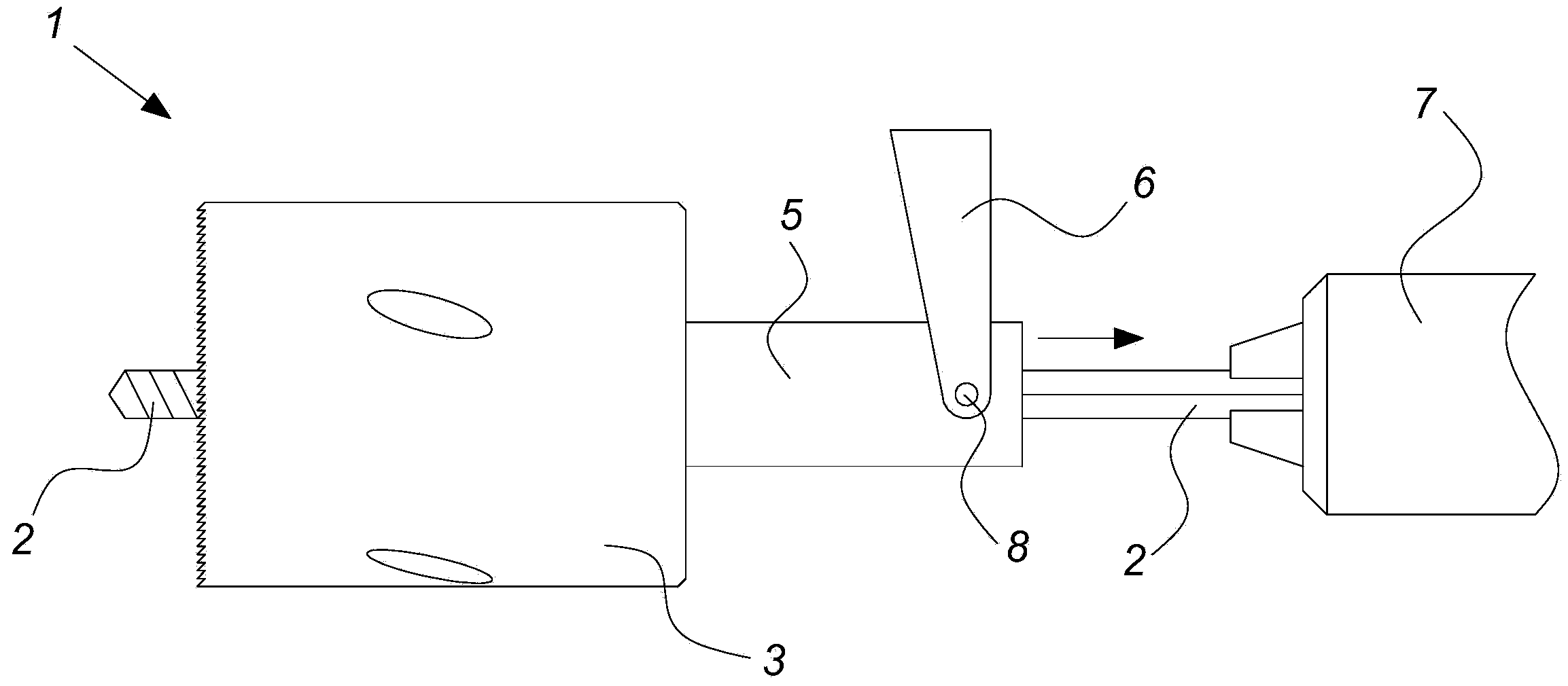

[0061] Figures 1a-2b are different side views of a hole saw assembly 1 according to an embodiment of the invention, the hole saw assembly 1 being arranged in two different ways.

[0062] The hole saw assembly 1 illustrated in these figures comprises a circular saw blade 3 firmly mounted and secured to a mount 5 , and a through center drill 2 having a tool end and a machining end. The circular saw blade 3 is configured such that its axis of rotation coincides with the axis of rotation passing through the center drill 2 .

[0063] Through the central drill 2 a drill 2 is formed at its tool end, slightly protruding from the plane defined by the cutting edge of the circular saw blade 3 . This means that the drill 2 can drill into the material at the center point of the hole to be drilled and that the drill 2 can be used as a guide for the actual sawing of the circular saw blade 3 . On the other hand, the through center drill 2 has a hexagonal sectional shape at its other end, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com