Headlamp quakeproof support device

A technology for a bracket device and a headlamp, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of loose shock-proof brackets, difficult tightening of nuts, and inability to efficiently assemble parts, and achieves convenient installation, Well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

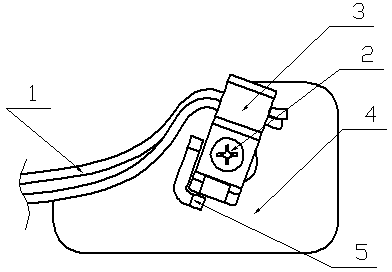

[0007] Depend on figure 1 Known, a headlamp anti-vibration support device is made up of shell 1, small iron bowl 2, M14 flat washer 3, M14 spring washer 4, M14 nut 5, and there is a small opening at the bottom of the shell on which M14 bolts that can move up and down are placed. A rubber washer 6 is added to the M14 bolt mentioned above, through the fastening effect of the rubber washer 6, it can be quickly assembled.

[0008] In the present invention, a rubber washer is added to the M14 bolt, and through the fastening effect of the rubber washer, the original loose and unfixed state is realized to be limited and stuck, and the effect is similar to the effect of nut fixing. When assembling, there is a small hole at the bottom of the shockproof work light shell to place M14 bolts (which can move up and down) as shown. Then insert the rubber washer into the bolt column to fix the M14 bolt relative to the lamp shell. Set the small iron bowl, M14 flat washer, M14 spring washer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com