Workpiece conveying device of eddy current flaw detector

An eddy current flaw detection and conveying device technology, applied in measuring devices, instruments, material analysis by electromagnetic means, etc., can solve the problem of high cost and achieve the effect of low cost, high operation efficiency, stable and reliable operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

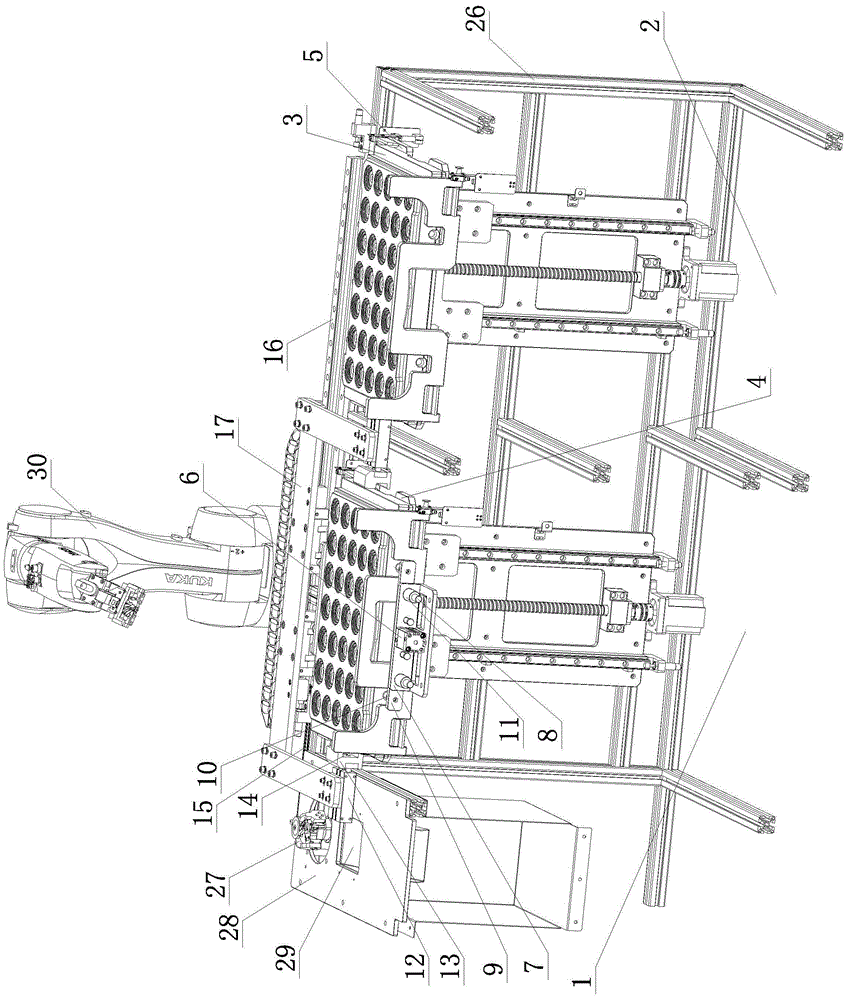

[0021] The present invention will be further described below in conjunction with accompanying drawing.

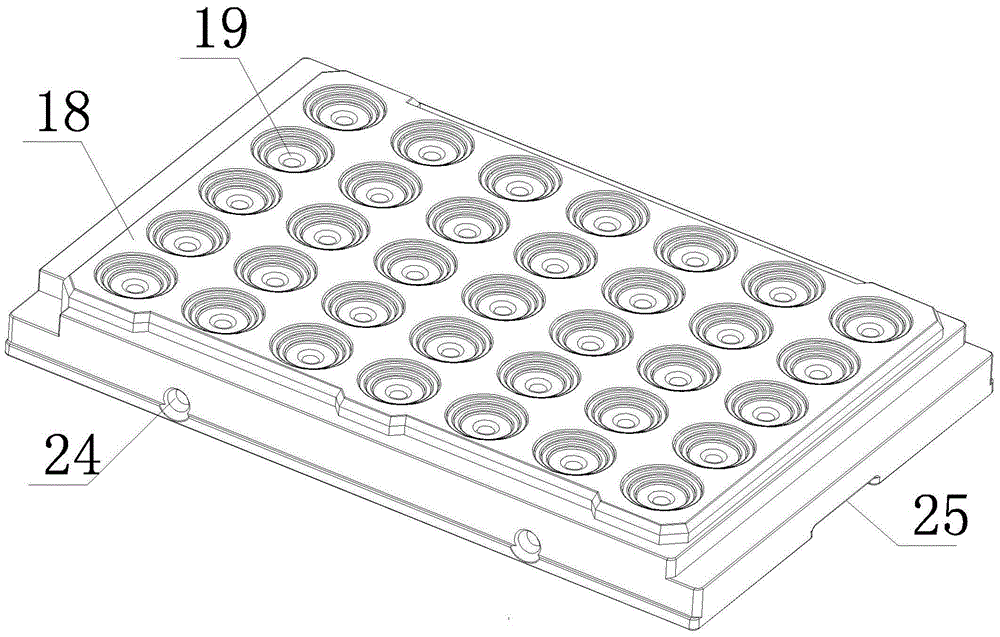

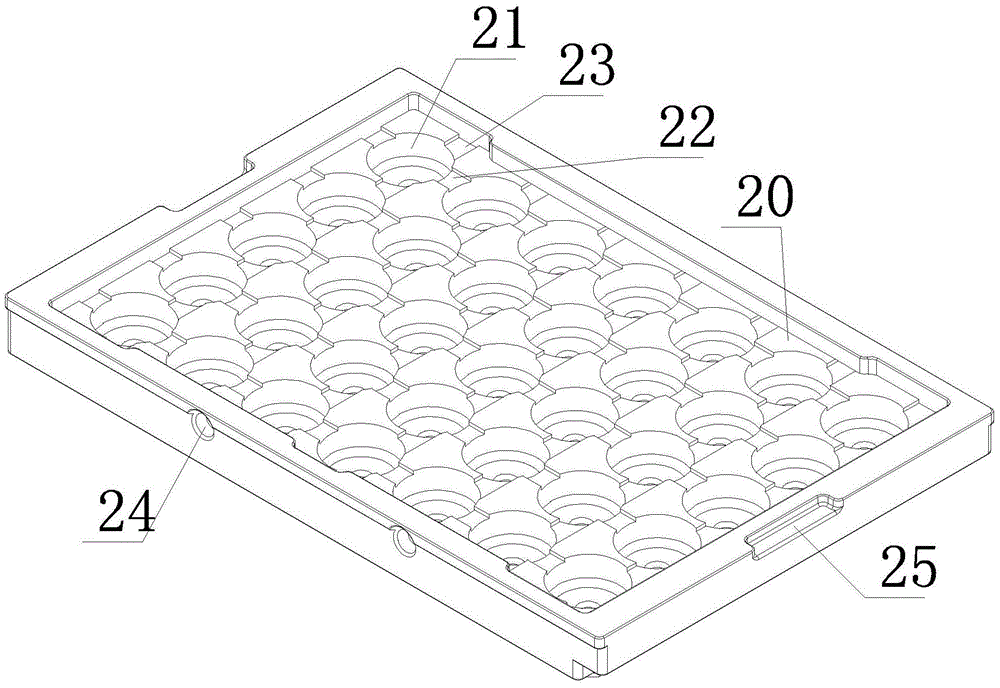

[0022] For the simplicity and clarity of the diagram, the relevant marks of the specific structure of the tray 3 are in figure 2 , 3 , 4, 5 marked, and figure 1 Not marked.

[0023] The workpiece conveying device of the eddy current flaw detection machine of the present invention includes an eddy current flaw detection module 27, an installation platform 28, a receiving bin 1, a storage bin 2, a tray 3, and the tray 3 is translated from the storage bin 2 to the receiving bin 1 and the tray is put down. 3, the pallet translation mechanism of 3, the installation platform 28 is provided with a warehouse 29 for unqualified workpieces, the warehouse 29 for unqualified workpieces is located in front of the eddy current flaw detection module 27, and behind the receiving bin 1 there is a The module 27 detects, and after the detection is completed, the workpieces that have been ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com