An automatic fixed-length cold shearing method and its device

A fixed-length, automatic technology, applied in the field of automation, can solve problems such as button production operations in a hurry, hidden safety hazards, and dangers, and achieve the effects of improving fault recovery capabilities, ensuring normal production, and improving work and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

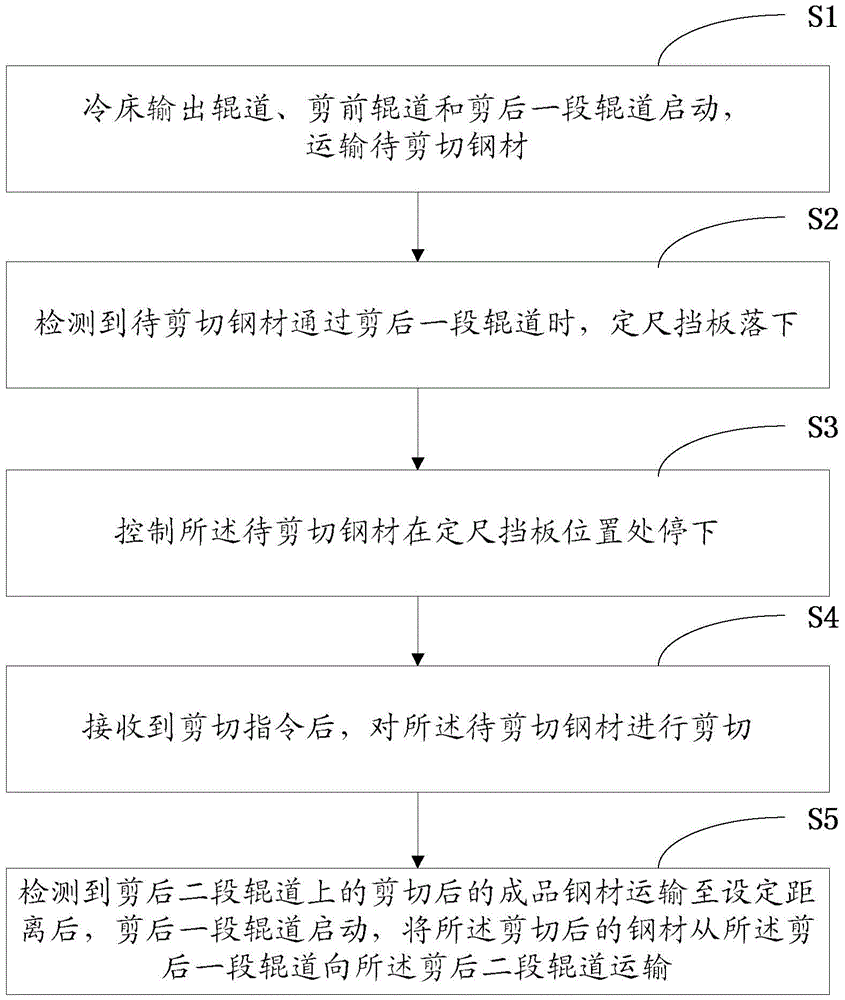

[0043] The present invention provides a kind of automatic fixed-length cold shear shearing method, please refer to figure 1 Shown, it is the embodiment one of a kind of automatic fixed length cold shear shearing method of the present invention, comprises:

[0044] Step S1, the cooling bed output roller table, the roller table before shearing and the roller table after shearing are started, and the steel to be sheared is transported;

[0045] Step S2, when it is detected that the steel to be cut passes through the last section of the roller table, the cut-to-length baffle falls;

[0046] When the fourth area sensor detects that the steel to be cut passes through, the baffle to length falls and enters the automatic positioning program for cutting to length; starting state;

[0047] Step S3, controlling the steel to be cut to stop at the position of the baffle;

[0048] Step S4, after receiving the cutting instruction, cutting the steel to be cut;

[0049] The operator needs ...

Embodiment 3

[0078] Embodiment 3 achieves the above effects, but it cannot guarantee that the group of steels are aligned, which will make the lengths of the steels obtained by the first shearing different, so it cannot guarantee that the finished steels are qualified.

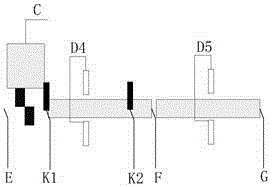

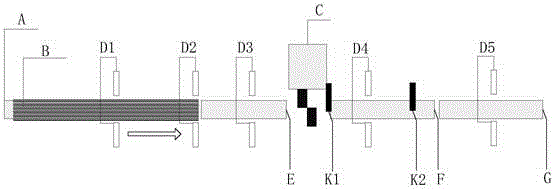

[0079] see Figure 4 As shown, it is a structural diagram of Embodiment 4 of an automatic fixed-length cold shearing system of the present invention, which is provided in this embodiment. The system of the present invention can also include a cooling bed output roller table A; steel to be sheared B ; Roller E before cutting; the third area sensor D3; the first area sensor D1, the second area sensor D2.

[0080] The cooling bed output roller table A is used to receive the steel material B to be cut from the cooling bed, and transmit the steel material B to be cut; the first area sensor D1 is located in the middle of the cooling bed output roller table, and is used to detect whether The steel to be sheared passes by; the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com