Rolling slot sealing machine control system based on PLC

A control system and sealing machine technology, applied in electrical program control, program control in sequence/logic controller, capacitor manufacturing, etc., can solve the problem of lack of overall machine control elaboration, etc., achieve convenient operation and maintenance, reduce the number of buttons, The effect of simplifying peripheral circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

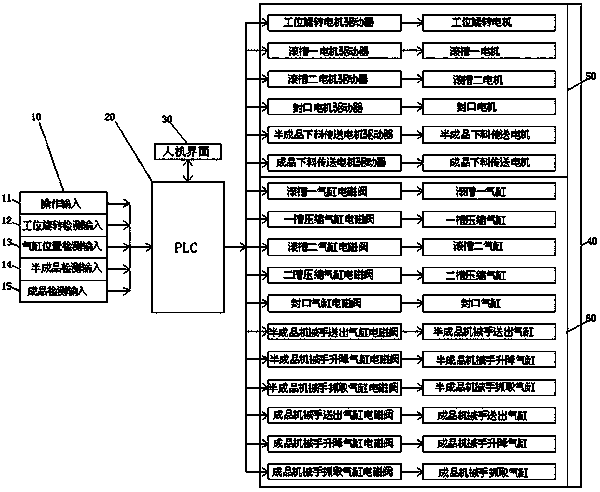

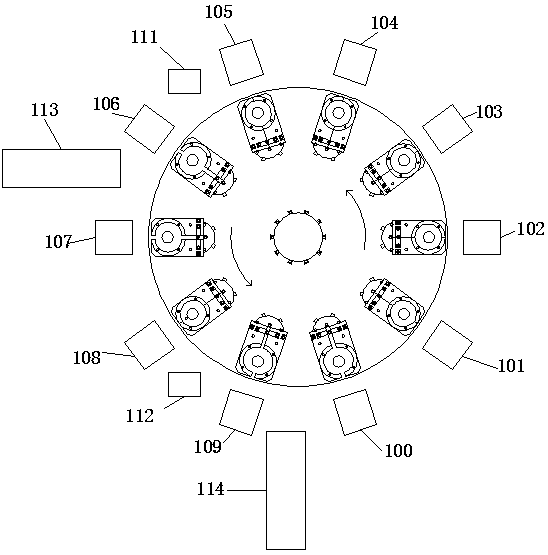

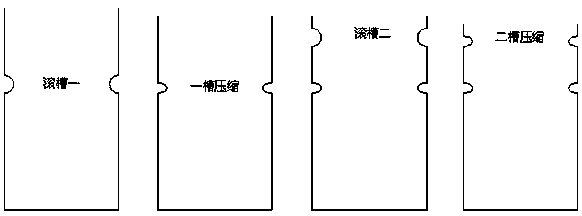

[0034] Such as figure 1As shown, the PLC-based rolling groove sealing machine control system of the present invention includes for program control: 1. Input signal acquisition system (10): operation input (11), used to control the operation and stop of the machine and fault reset, including Start button, stop button, reset button; station rotation detection input (12), used to detect the deceleration position and stop when the station rotates, including station rotation stop position detection photoelectric switch PS1, station rotation deceleration position detection photoelectric switch PS2 ; Cylinder position detection input (13), used to detect the piston position of each cylinder, including rolling groove-cylinder upper limit detection switch S1, rolling groove-cylinder lower limit detection switch S2. One-slot compression cylinder upper limit detection switch S3. Roll groove 2 cylinder upper limit detection switch S4, roll groove 2 cylinder lower limit detection switch S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com