Bamboo fence weaving machine

A technology of bamboo hedge boards and weaving machines, applied in the direction of mechanical equipment, sugarcane machining, etc., can solve the problems of low production efficiency and high production cost, and achieve the effect of improving production efficiency, reducing production cost and making significant progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

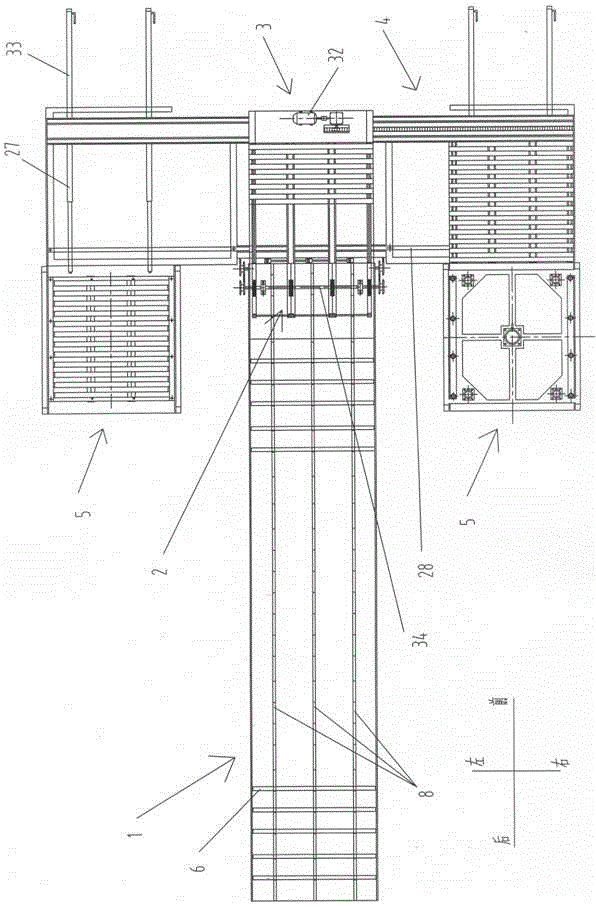

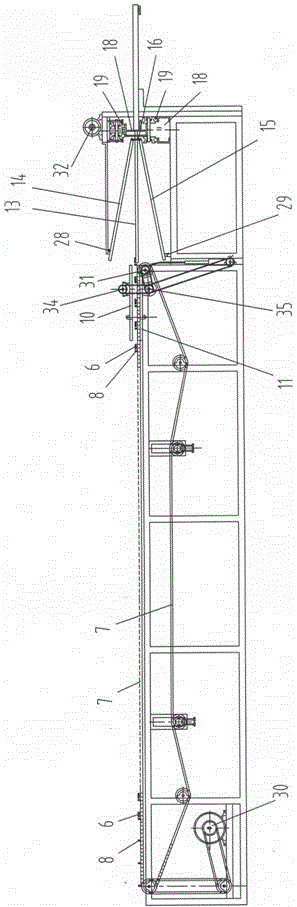

[0028] Referring to the accompanying drawings, the bamboo hedgerow weaving machine in the present embodiment includes a horizontal bar conveying mechanism 1, a horizontal bar pre-pressing mechanism 2, a weaving mechanism 3, a semi-finished product conveying mechanism 4 and a forming mechanism 5, and the horizontal bar pre-pressing mechanism is arranged on The front end of the horizontal bar conveying mechanism, the horizontal bar conveying mechanism cooperates with the horizontal bar pre-pressing mechanism to send the horizontal bar to the weaving mechanism, and the semi-finished product conveying mechanism is arranged between the weaving mechanism and the forming mechanism. The horizontal strip conveying mechanism transports the horizontal strips to the horizontal strip pre-pressing mechanism, and the horizontal strips are pre-pressed at the horizontal strip pre-pressing mechanism to form a wave shape. The pressing mechanism cooperates to send the bar to the weaving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com