Lifting and descending hydraulic system of scissor fork type aerial lift vehicle platform

A technology for aerial work vehicles and hydraulic systems, which is applied in the direction of lifting devices, fluid pressure actuators, servo motor components, etc., can solve problems such as reduced cylinder life, high self-priming resistance, and damage to seals, so as to prolong the service life, Easy oil absorption, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

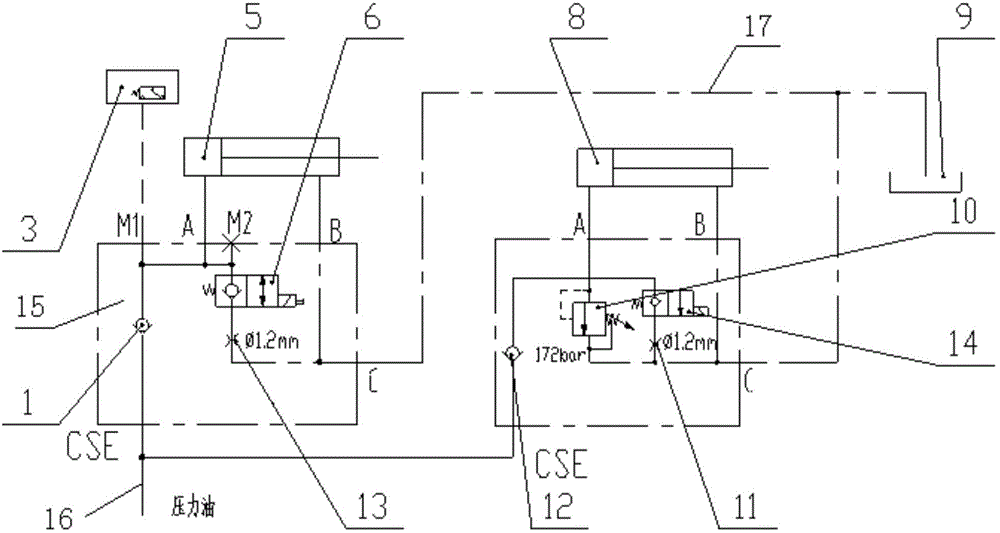

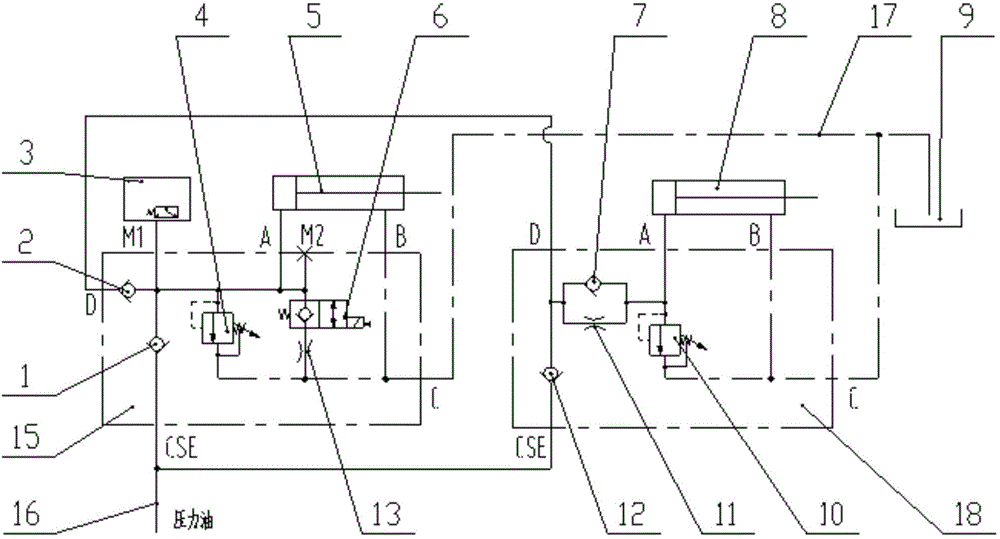

[0020] see figure 1 , the existing scissor-type aerial work vehicle walking hydraulic system, including the pressure oil pipe 16, the first one-way valve 1, the overweight sensor 3, the lower lifting cylinder 5, the two-position two-way manual electromagnetic reversing valve 6, the upper lifting Oil cylinder 8, fuel tank 9, second overflow valve 10, second damper 11, second check valve 12, first damper 13, two-position two-way electromagnetic reversing valve 14. When the platform is lifted, the pressure oil enters the first check valve 1 and the second check valve 12 respectively, and then enters the lower lifting cylinder 5 and the upper lifting cylinder 8 respectively. When the platform is lowered, the 2-position 2-way manual electromagnetic directional valve 6 and the 2-position 2-way electromagnetic directional valve 14 are energized, and the hydraulic oil passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com