Coal shearer forced lubrication system based on gravity control

A forced lubrication, shearer technology, applied in the direction of gear lubrication/cooling, mechanical equipment, transmission parts, etc., can solve the problems of easy damage of downhole valve group, long oil absorption length, easy blockage of pipes, etc., to achieve good protection, Easy to maintain and improve the effect of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

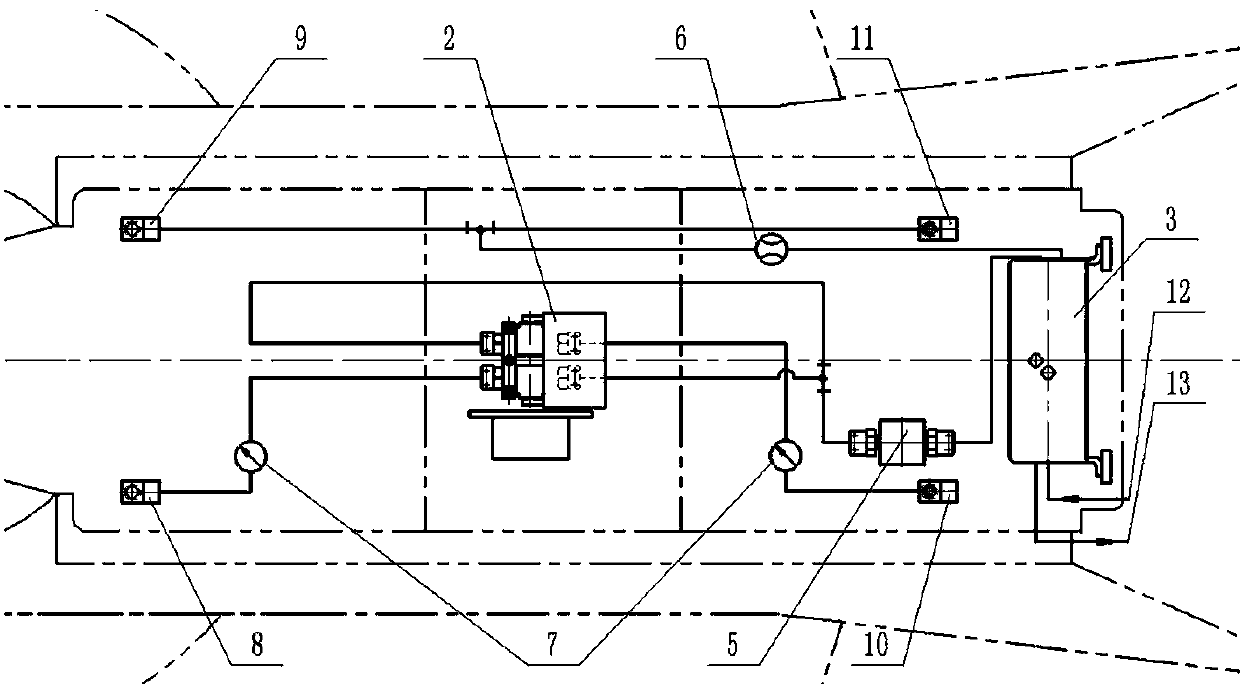

[0030] Such as figure 1 , 4 As shown, a forced lubrication system for coal shearers based on gravity control is arranged on the cavity wall of the goaf side of the rocker arm as a whole. The oil inlet and oil return ends of the system are respectively connected to the pump station system The high-pressure oil outlet 12 is connected to the oil tank 13 of the pump station system;

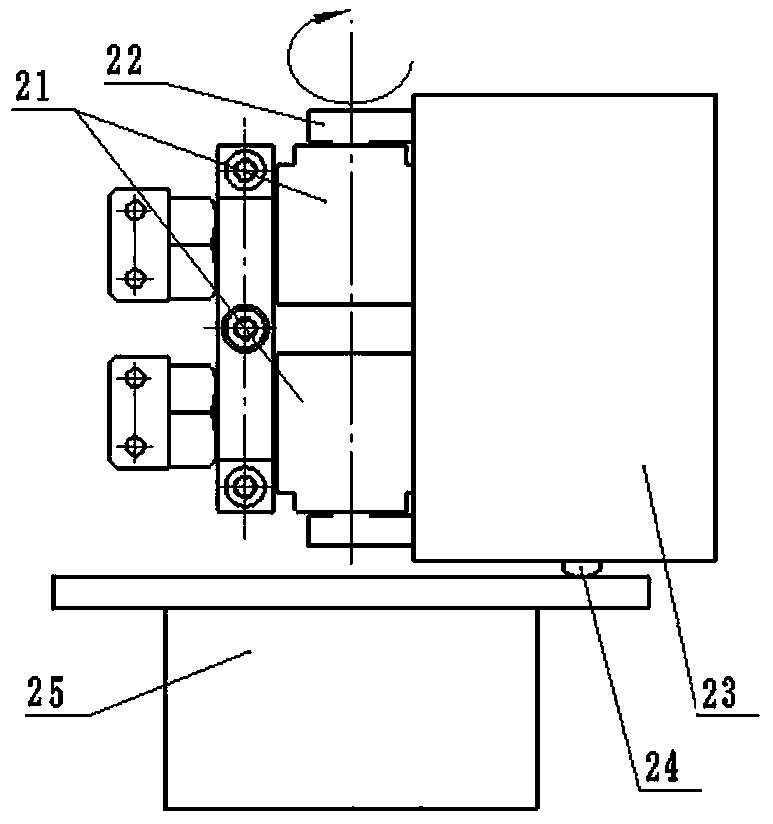

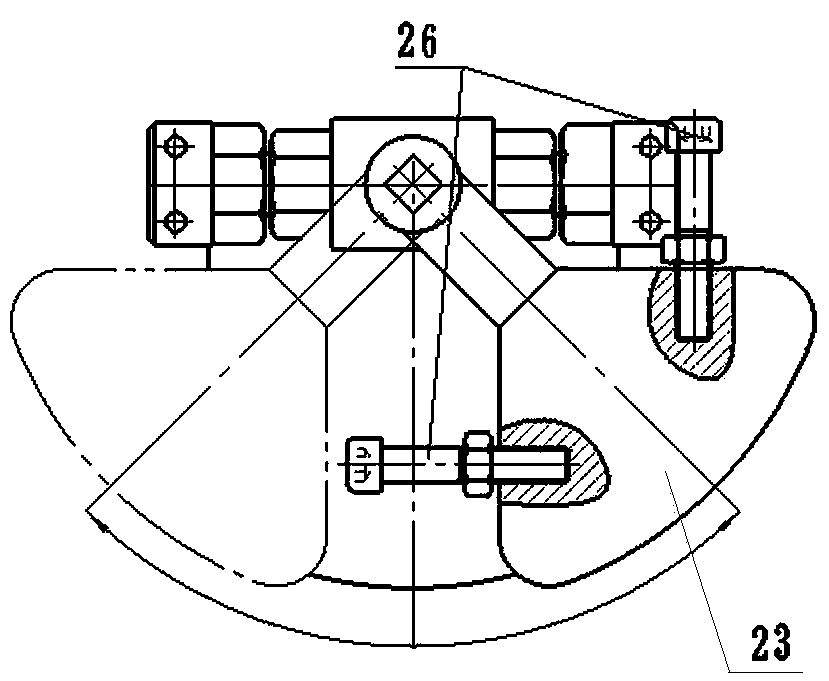

[0031] The system includes an oil pool 1 at the planetary head of the rocker arm, a reversing switch assembly 2, a motor pump 3 and an oil pool 4 on the rocker arm motor side. The reversing switch assembly 2 includes two ball valves 21, a handle 22, and a weight 23 , the rotating shafts of the valve plates of the two ball valves 21 are connected to the handle 22 at the same time, and the handle 22 is connected to the weight 23;

[0032] The oil pool 1 at the planetary head of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com