Production device for minimized spangle on surface of cold-rolled steel sheet

A technology for cold-rolled steel sheets and production equipment, applied in coating, metal material coating technology, hot-dip galvanizing technology, etc., can solve the problems of irregular surface of cold-rolled steel sheets, uneven spangles, spangles, etc., and achieve reduction The effect of production cost, stable production operation and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

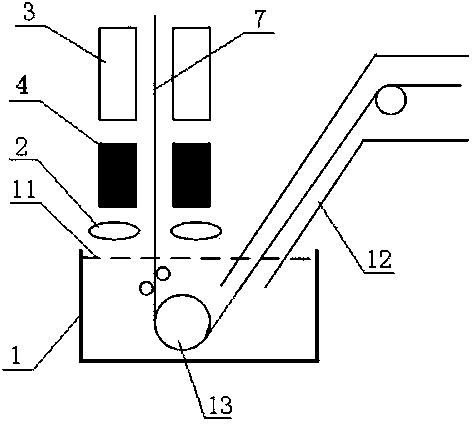

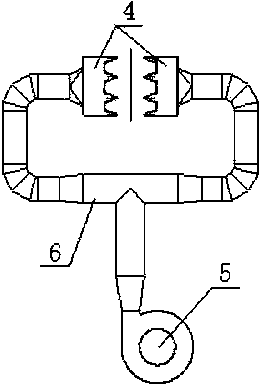

[0016] Such as figure 1 with figure 2 As shown, the small spangle production device on the surface of the cold-rolled steel sheet of the present invention includes an air knife 2 and a post-plating cooling bellows 3 positioned at the top of the zinc pot 1 at intervals in sequence, and also includes an air spray box 4 and a fan 5, and the fan 5 passes through the pipeline. 6 is connected to the air spray box 4, and the air spray box 4 is arranged between the air knife 2 and the post-plating cooling wind box 3 and symmetrically arranged on both sides of the cold-rolled steel plate 7.

[0017] Further, the distance between the bottom of the air spray box 4 and the zinc liquid surface 11 of the zinc pot 1 is 1000-2300mm, and the distance between the top of the air spray box 4 and the post-plating cooling bellows 3 is 100-2000mm. The distance between the spout of the spray box 4 and the surface of the cold-rolled steel plate 7 is 60-300mm.

[0018] Further, the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com