Space truss type non-pneumatic tire

A non-pneumatic tire, truss technology, used in non-pneumatic tires, tire parts, transportation and packaging, etc., to improve comfort, reduce quality, and eliminate high-decibel noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

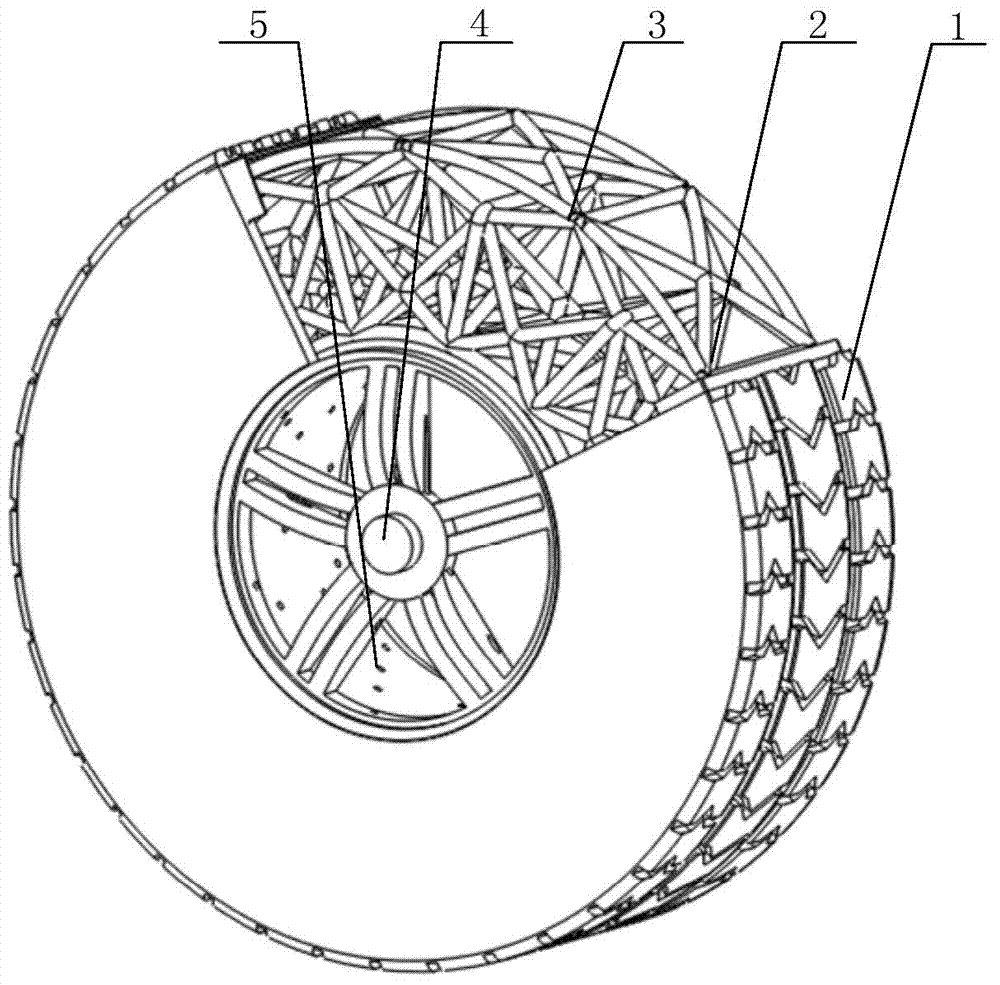

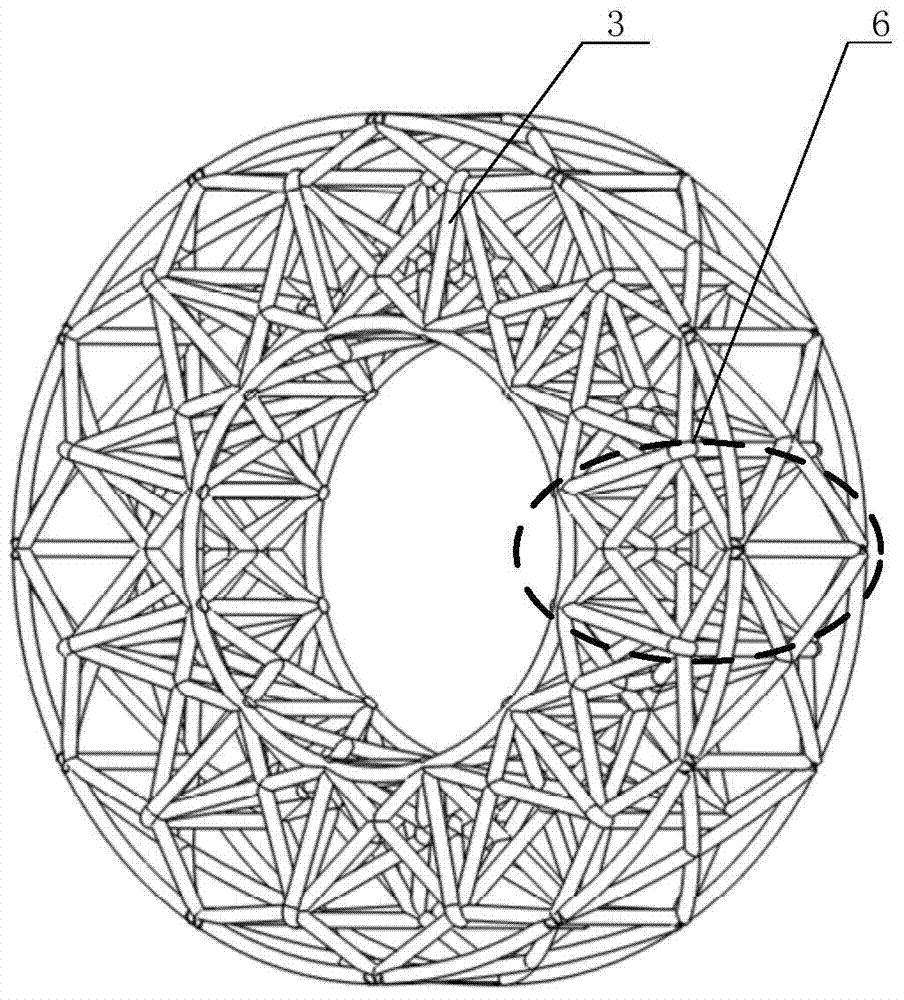

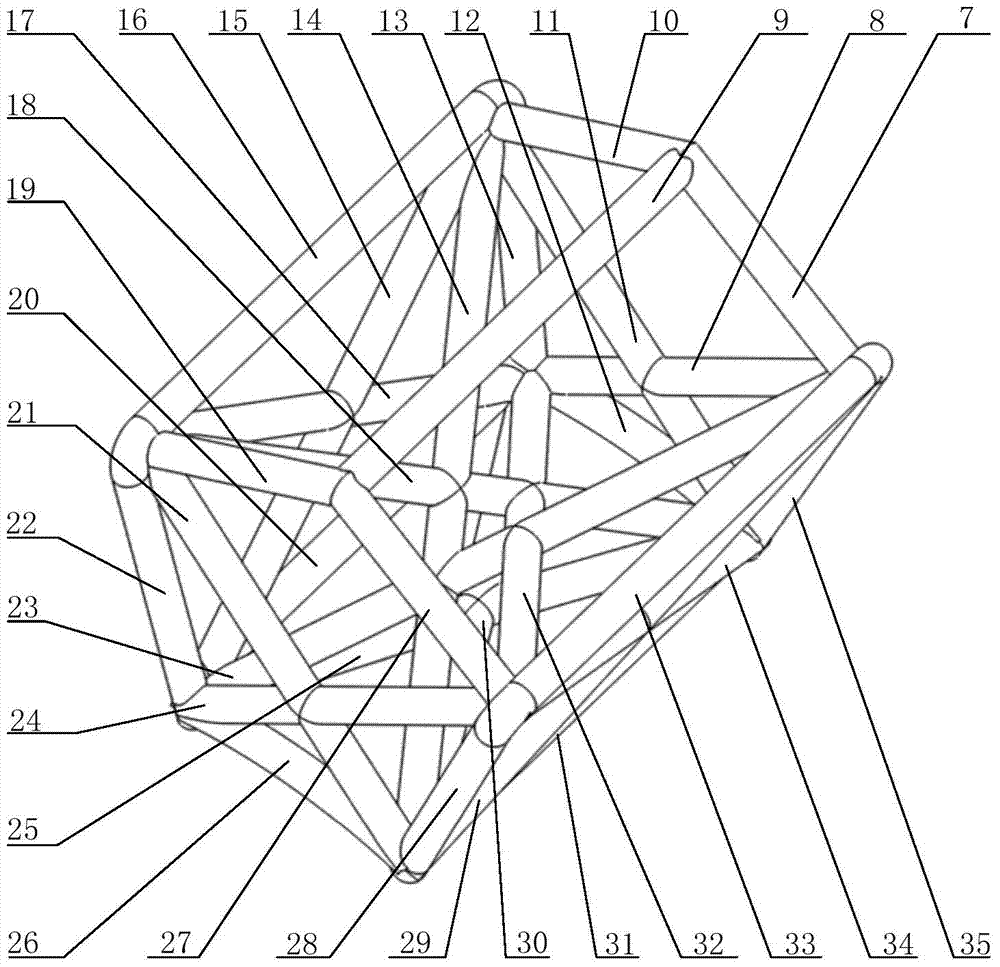

[0026] The structural principles and specific implementation methods of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] figure 1 It is a schematic diagram of the overall structure of a space truss-type air-free tire provided by the present invention. The air-free tire includes a rubber structure 1, a steel wire ring belt 2, and a truss structure assembly 3. The geometric center is distributed in the circumferential direction; the rubber structure, the steel wire ring belt and the truss structure assembly form a composite elastic body. Described rubber structure 1 is the airtight cavity structure that is made up of rubber tread 37, rubber sidewall 38 and rubber sealing strip 39, is provided with rubber ventilation hole 5 on rubber sealing strip 39; The steel wire ring belt slot 36, the steel wire ring belt 2 is installed in the steel wire ring belt slot hole 36 of the rubber structure 1; the truss structure assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com