Arrangement controlling clearance of sliding bearing

一种滑动轴承、轴承的技术,应用在间隙的装置领域,能够解决冷却系统反应缓慢、消耗大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

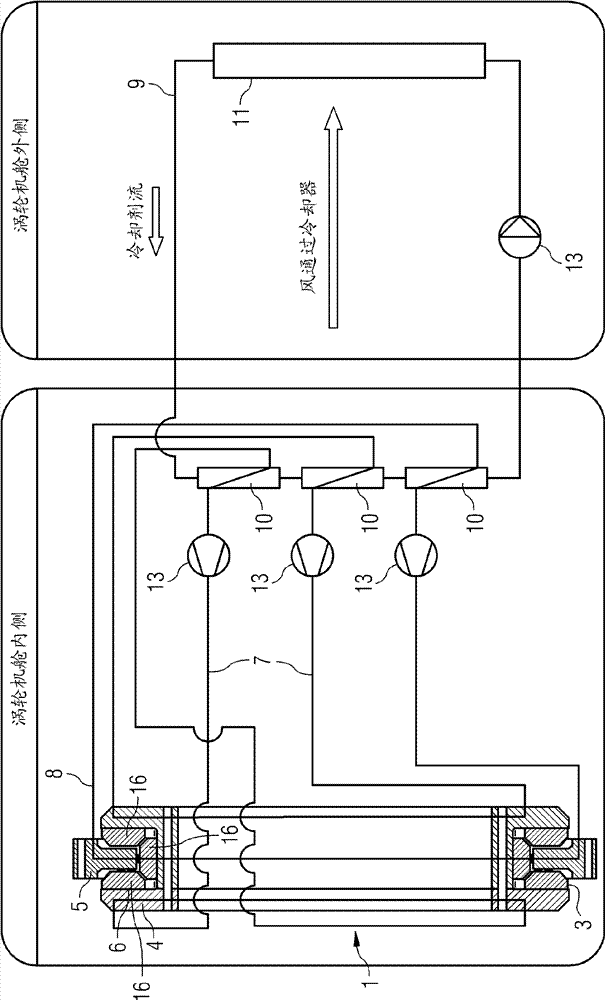

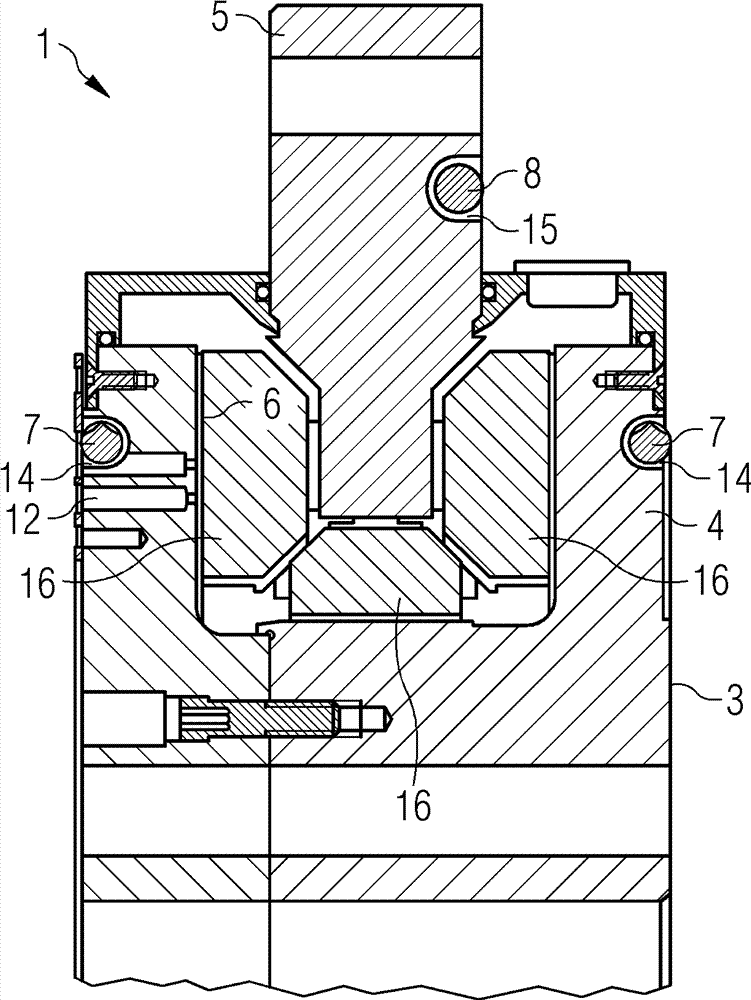

[0127] figure 1 A schematic view of a first embodiment of a bearing arrangement is shown.

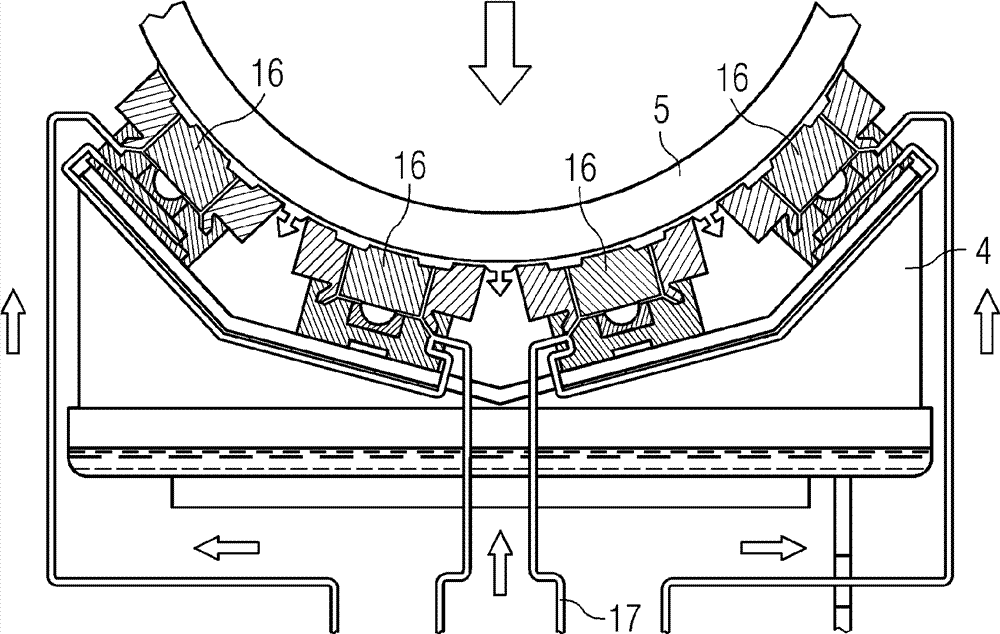

[0128] figure 1 A bearing arrangement 1 comprising bearings is shown. The bearing includes a first bearing shell 4 and a second bearing shell 5 . Bearing pads 16 are attached to the second bearing shell 5 . During operation of the bearing, the bearing pads 16 slide along the surface of the first bearing shell 4 .

[0129] A certain gap 6 is provided between the first bearing shell 4 and the second bearing shell 5 . The gap 6 has to be kept within certain limits in order to avoid damage eg at bearings or the wind turbine.

[0130] The first circuit 7 is arranged on the first bearing shell 4 . The first circuit 7 comprises a first fluid. The first circuit 7 is in thermal contact with the first bearing pad 4 so as to enable the transfer of thermal energy, eg heat, between the first bearing pad 4 and the first fluid. Thus, the first bearing shell 4 can be cooled or heated by the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com