A method for measuring and inspecting the radius of the inner wall of the curved roof of the assembled channel

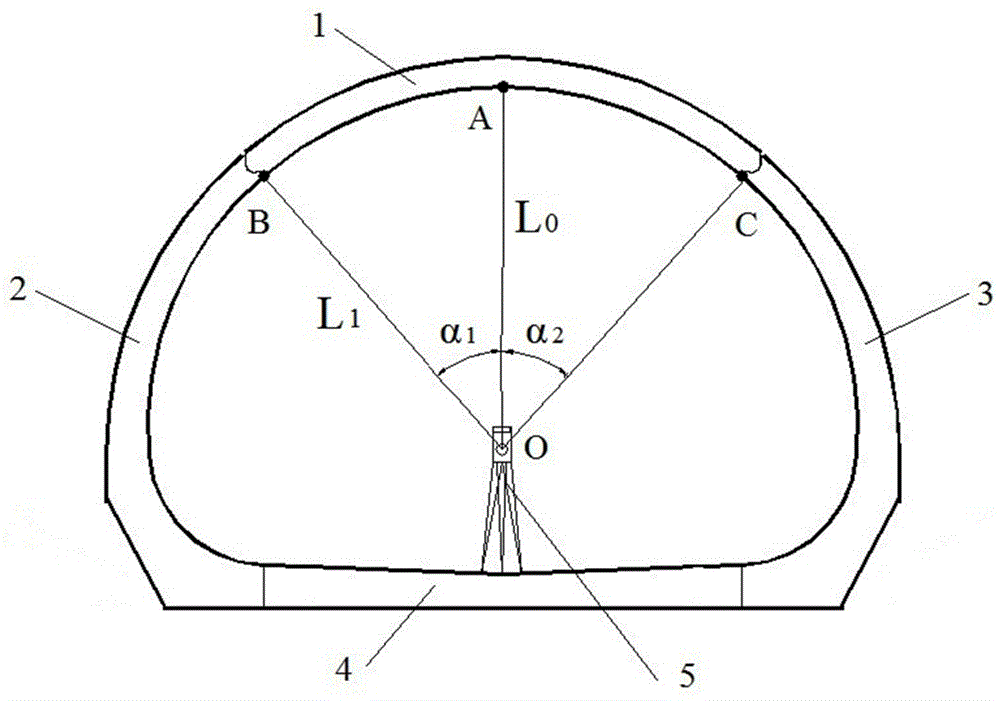

An inspection method and technology of an arc-shaped top plate are applied in the field of measurement and inspection of fabricated channels, which can solve the problem that the radius cannot be directly measured, and achieve the effect of small amount of measurement data and simple operation and calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

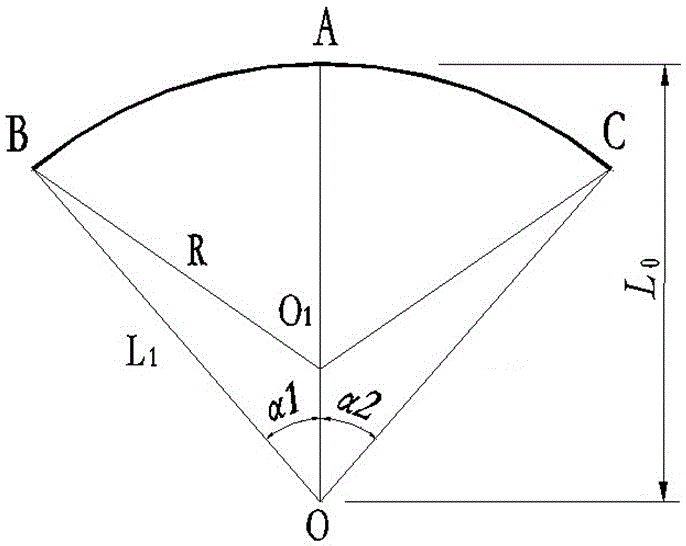

Method used

Image

Examples

Embodiment 1

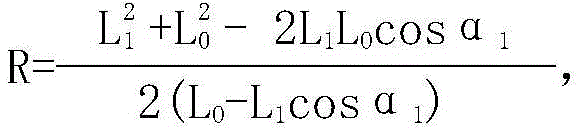

[0030] Embodiment 1: measured α 1 = α 2 = 45°, L O = 1.400m, L 1 =1.200m, first assume L O ﹥R, put the data into the formula (1), get R=0.9285m, which is in line with the assumption, so R=0.9285m.

Embodiment 2

[0031] Embodiment 2: measured α 1 = α 2 = 60°, L O = 1.000m, L 1 =1.200m, first assume L O ﹥R, put the data into formula (1), get R=1.55m, which does not meet the assumption, so it should be calculated according to formula (2). Substituting the data into the formula (2), obtain R=1.1375m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com