Patents

Literature

98results about How to "Valid inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3-dimensional image creation device, 3-dimensional image reproduction device, 3-dimensional image processing device, 3-dimensional image processing program, and recording medium containing the program

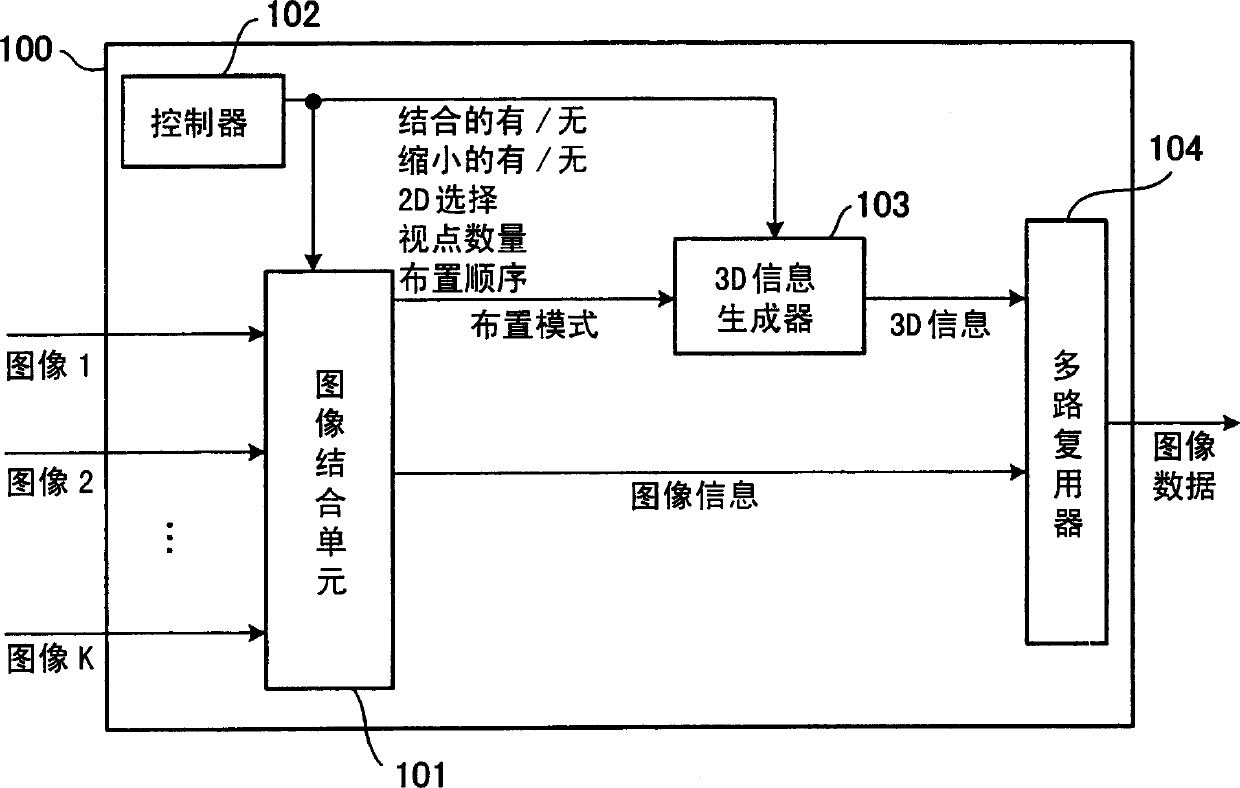

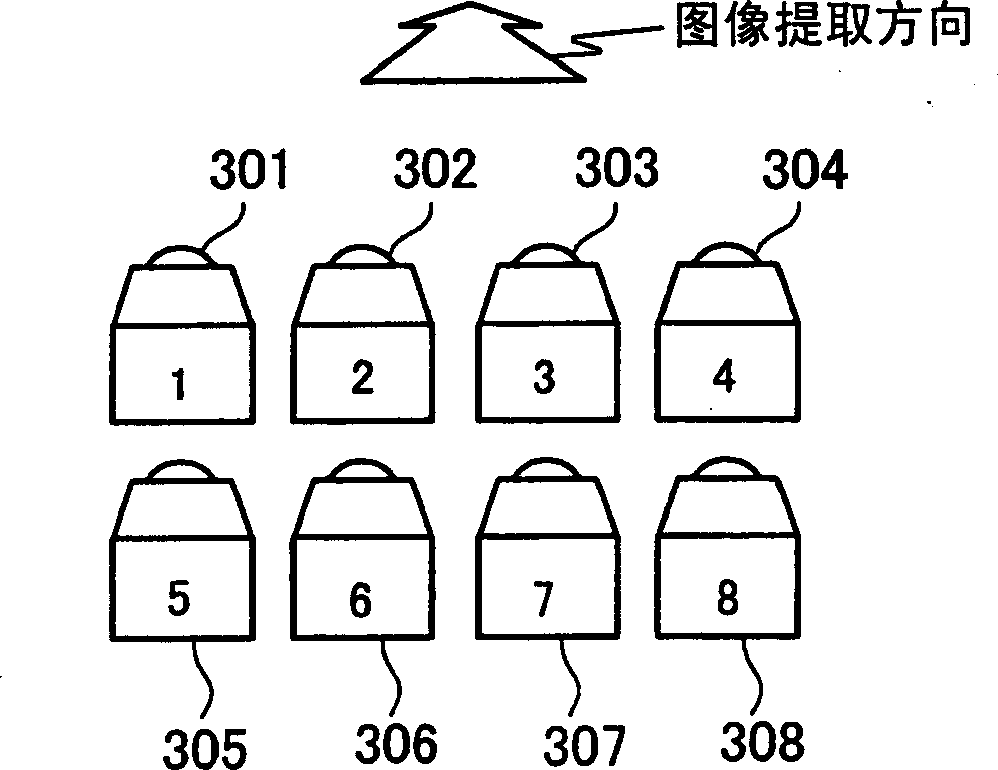

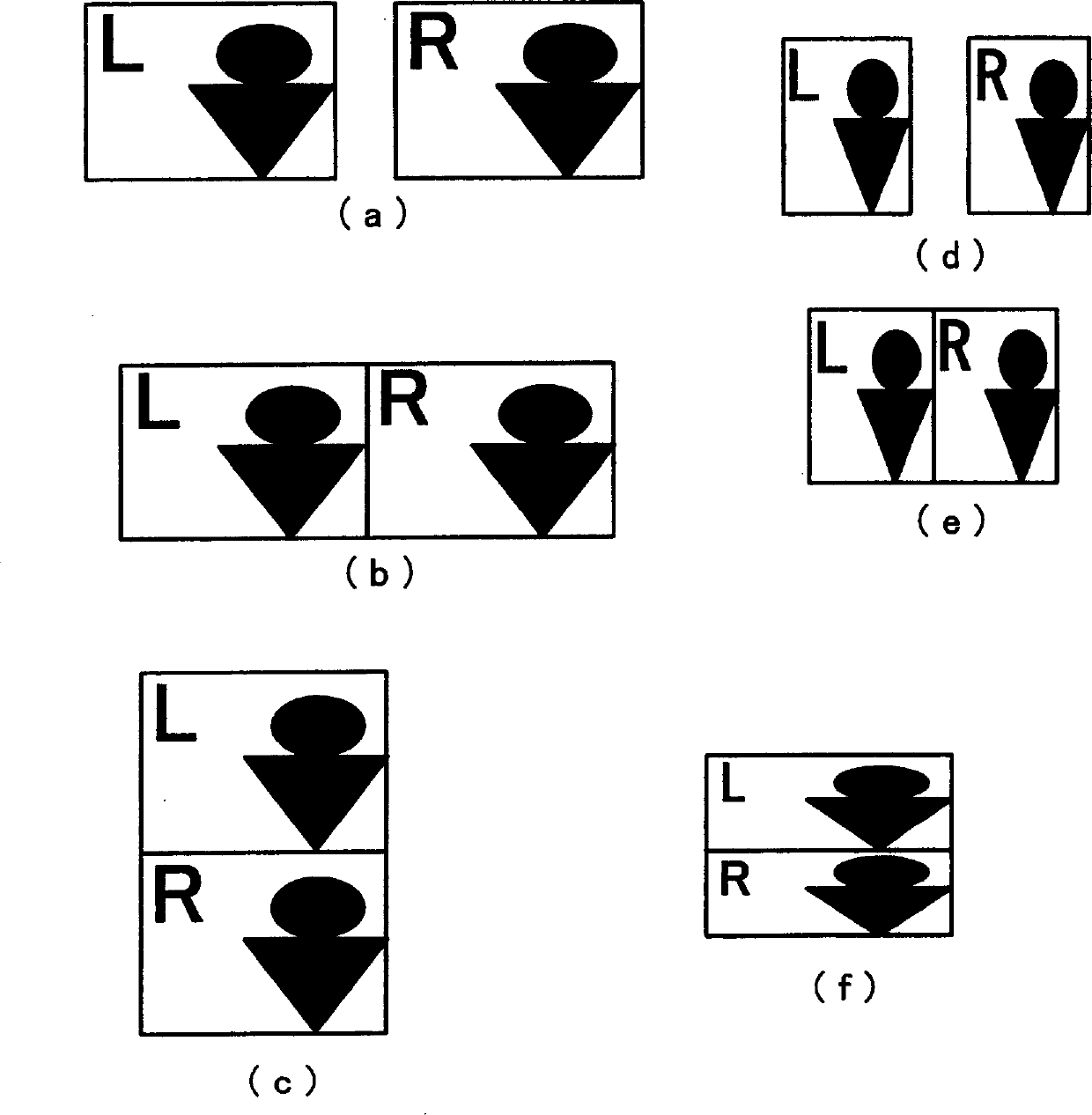

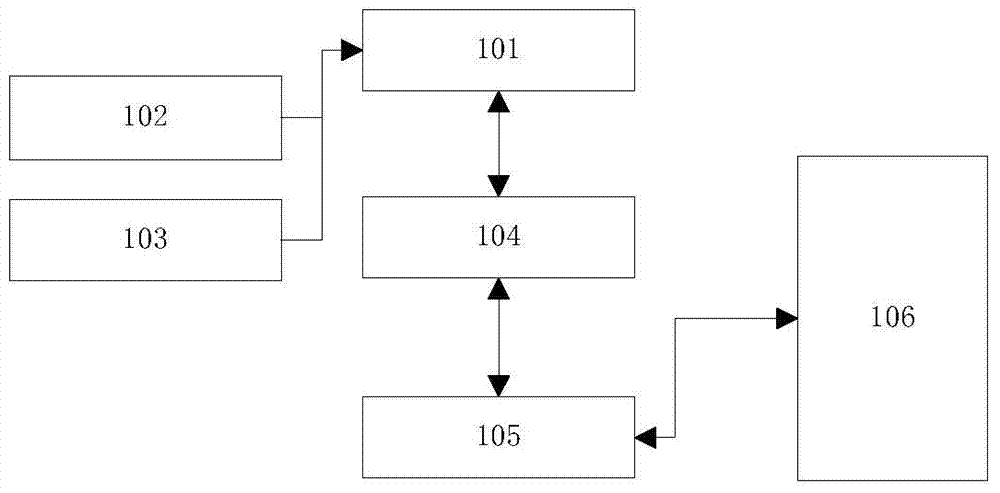

An image signal composed of sequential frames is input to a 3-dimensional image creating apparatus, frame by frame. A controller ( 102 ) designates the presence / absence of reduction, the presence / absence of joining and 2D select. An image converter ( 101 ) creates image data in the format designated by the presence / absence of reduction and the presence / absence of joining. A 3D information creator( 103 ) creates 3D information necessary for displaying the image as a 3-dimensional image by formatting the presence / absence of reduction, the presence / absence of joining and 2D select. A multiplexer( 104 ) converts image data and 3D information in a predetermined format and outputs them to the outside. In this way, it is possible to make the image data for 3-dimensional display versatile and select an arbitrary viewpoint image efficiently.

Owner:SHARP KK

Immunochromatography detection method

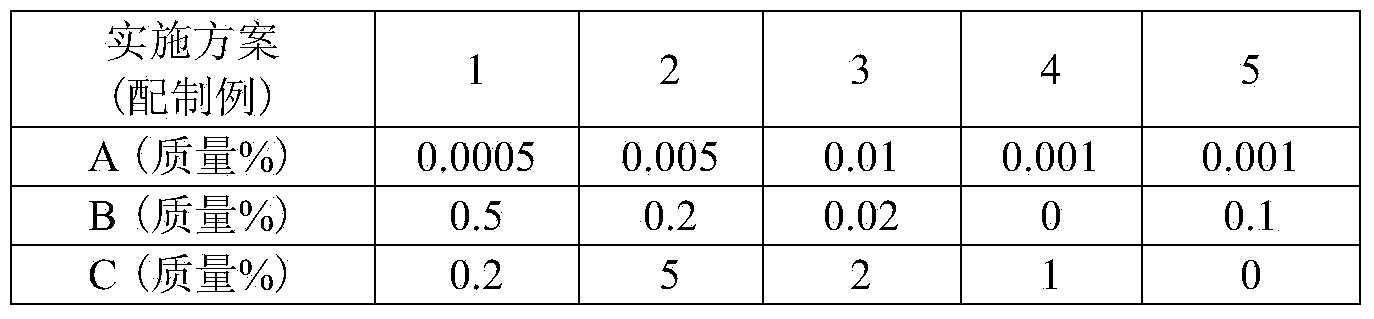

InactiveCN104204802ASuppresses non-specific reactionsReduce sensitivityMaterial analysisAnalyteArginine

The present invention provides an immunochromatography detection method whereby non-specific reactions can be minimized. The present invention relates to an immunochromatography detection method including: a step of adding an analyte diluted solution containing an analyte to a chromatography medium; a step of recognizing the detection target by a labeling substance which has been modified with gold nanoparticles, and which is retained in a dried state by a labeling substance retaining part; a step of developing a complex of the labeling substance and the detection target as the mobile phase; and a step of detecting the detection target in the developed mobile phase, by an assessment part, wherein the immunochromatography detection method is characterized in that the labeling substance is protected by polyalkylene glycol having one or more mercapto groups and / or a derivative thereof, and then retained in a dried state, together with arginine and casein, in the labeling substance retaining part.

Owner:TANAKA PRECIOUS METAL IND

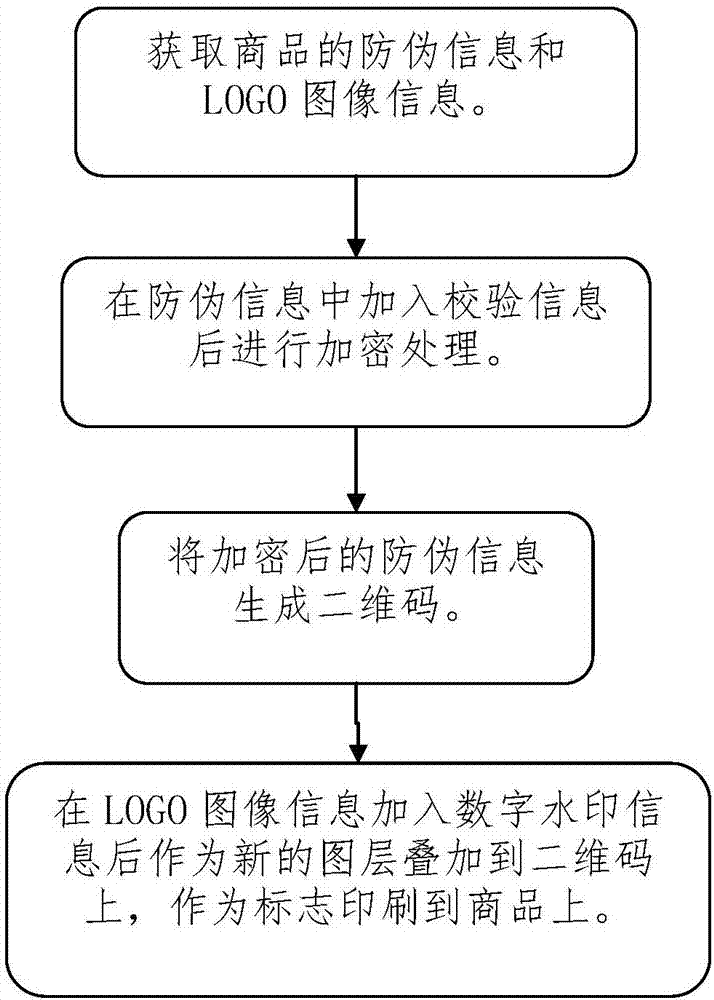

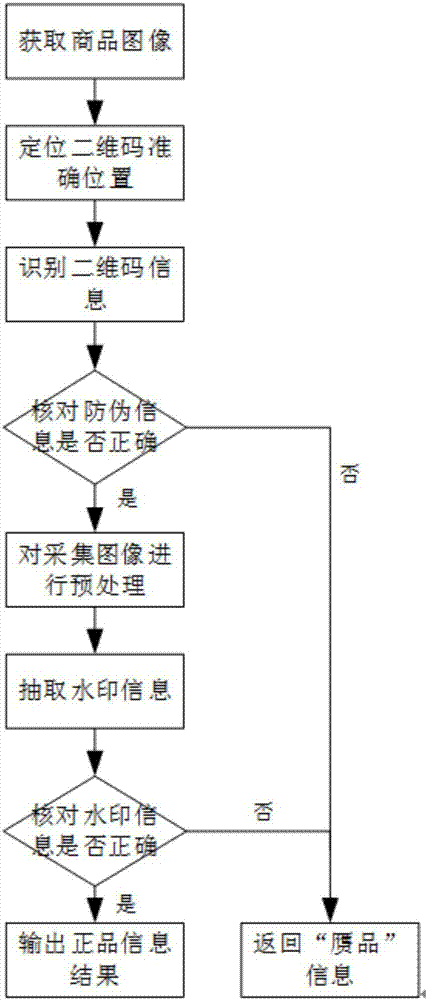

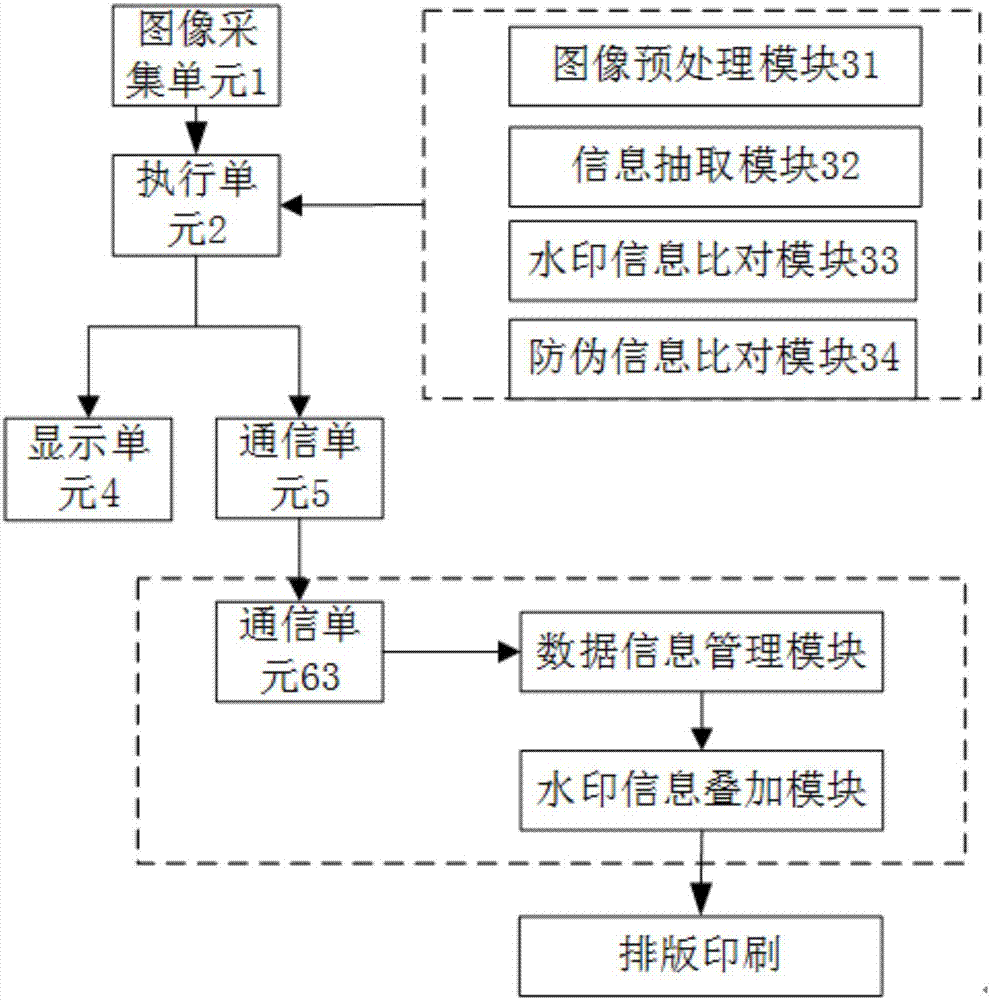

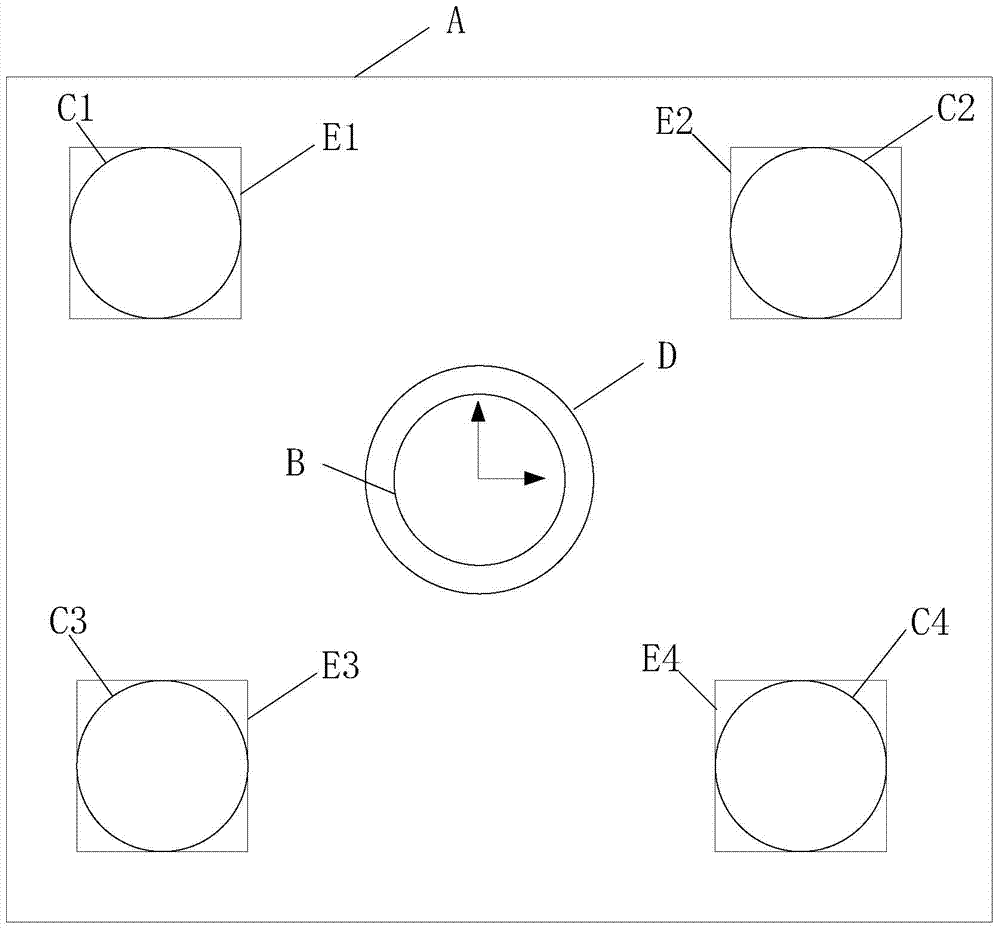

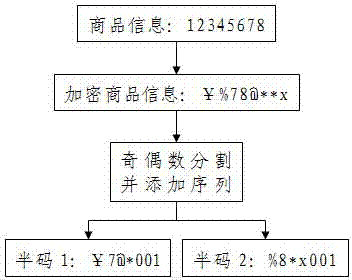

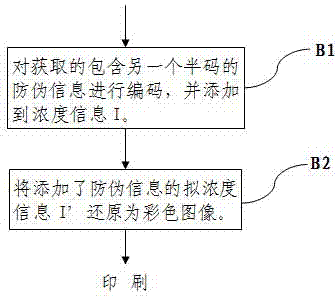

Two-dimensional code superposition digital watermarking method, identification method and identification system thereof

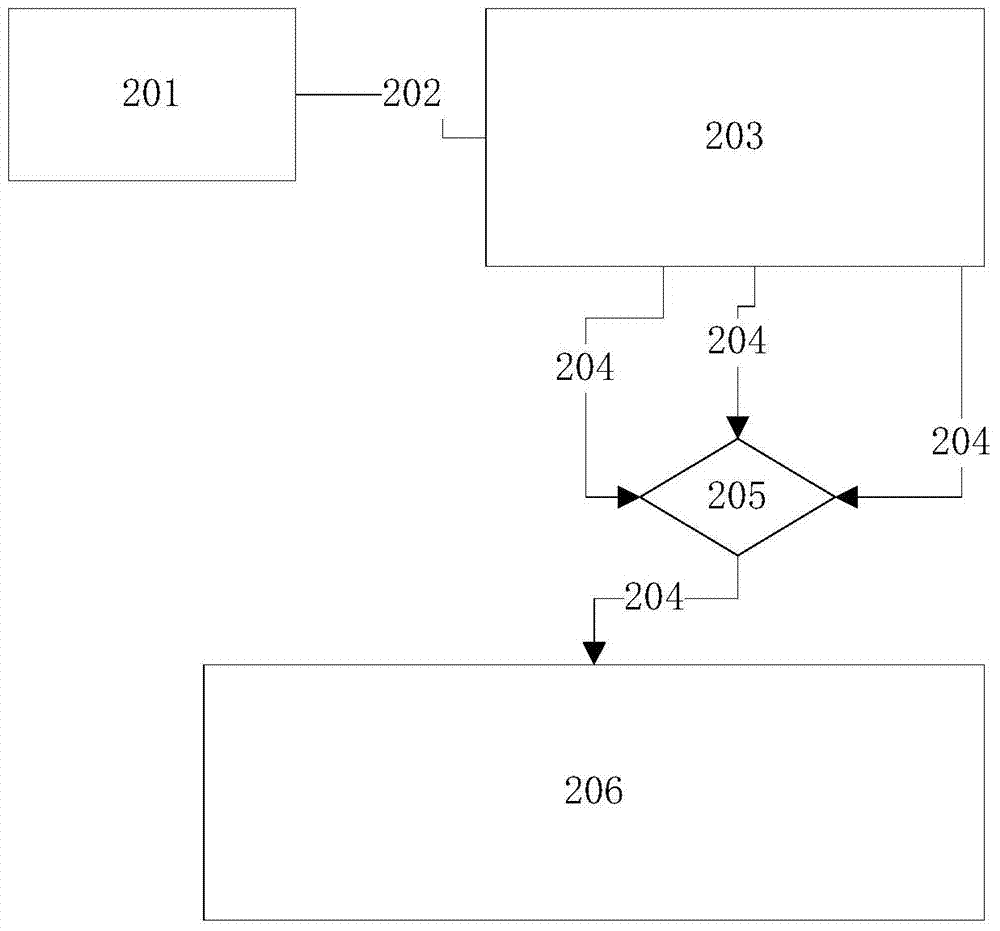

PendingCN106960411AImprove securityIncrease the difficulty of copyingImage data processing detailsCommerceDigital watermarkingLight source

The invention relates to a two-dimensional code superposition digital watermarking method, an identification method and an identification system thereof. The two-dimensional code superposition digital watermarking method comprises the following steps of firstly, acquiring anti-fake information and LOGO image information of a commodity; then adding verification information into the anti-fake information and then carrying out encryption processing; and then generating a two-dimensional code through encrypted anti-fake information; and finally, adding digital watermarking information in the LOGO image information, then taking as a new layer and superposing to the two-dimensional code so as to form a new image, and then taking as a sign and printing on the commodity. The printed commodity can acquire decomposition which is basically consistent with the decomposition of an original image on a visual sense aspect under a standard visible light source. Anti-fake information copy difficulty and an anti-fake coefficient are high so that non-authoritative copy can be prevented. Based on a condition that a commodity printing flow is not changed, commodity printing cost is reduced. Simultaneously, the verification information and the anti-fake information of encryption processing are added so that extraction robustness is increased. Digital watermarking is added in a LOGO image so that safety is high and an anti-fake capability is high too.

Owner:DANDE IMAGE MASTER CO LTD ZHUHAI

Method and system for mobile phone antenna coupling test on production line

ActiveCN104506252AImprove qualityIncrease intensificationTransmitters monitoringElectromagentic field characteristicsTest efficiencyProduction line

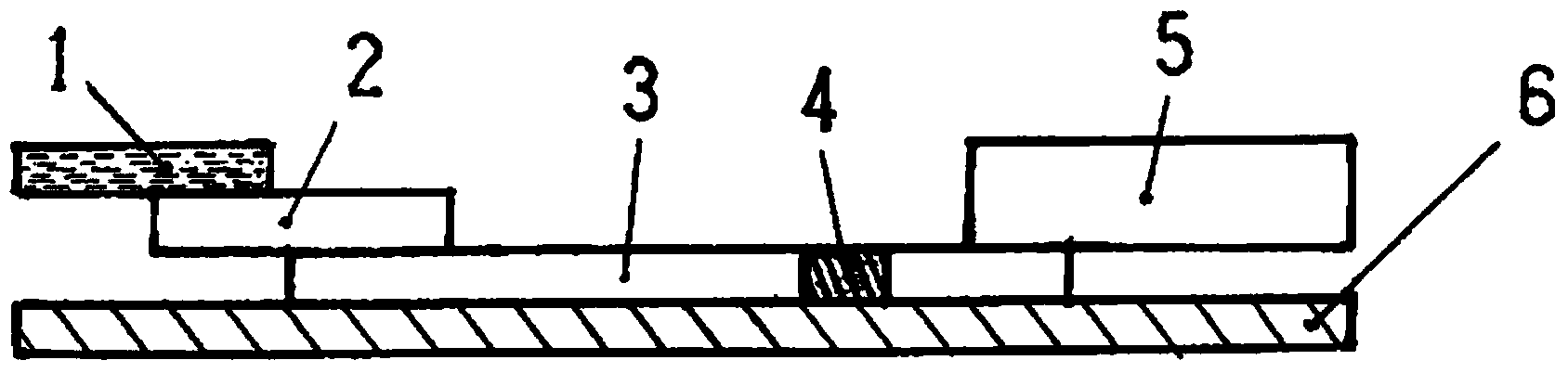

The invention discloses a method and a system for mobile phone antenna coupling test on a production line. The system comprises a coupling test module, an industrial personal computer, a multi-signal-source device, radio-frequency cables, a combiner and a coupling shielding box. The coupling test module comprises mobile internal test software for coupling test of a to-be-tested mobile phone in set process; the industrial personal computer is connected with the multi-signal-source device and used for configuration of parameters of the multi-signal-source device and controlling a transmission channel of the multi-signal-source device to open or close; the multi-signal-source device under control of the industrial personal computer is used for generating radio-frequency signals with multiple frequency points for mobile phone antenna coupling; the radio-frequency cable is arranged between the multi-signal-source device and the combiner and between the combiner and the coupling shielding box respectively; the coupling shielding box is used for placement of at least one mobile phone and used for broadcast type parallel coupling test of mobile phones. The method and the system for mobile phone antenna coupling test on a production line have the advantage that test efficiency and precision can be improved.

Owner:上海鑫测信息技术有限公司

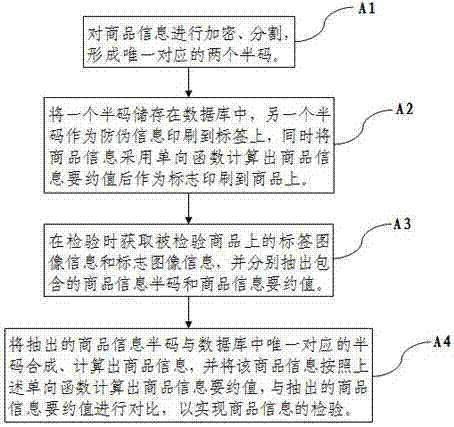

Printing inspecting method and device of commodity information

ActiveCN103761656AValid inspectionImprove securityCharacter and pattern recognitionImage data processing detailsOne-way functionLibrary science

The invention relates to a printing inspecting method and device of commodity information. The printing inspecting method of the commodity information comprises the steps that the commodity information is encrypted and divided to form two unique and corresponding half codes firstly; then one half code is stored in a database, the other half code serves anti-fake information and is printed on a label, and meanwhile a commodity information offer value is calculated based on the commodity information through a one-way function and is printed on a commodity serving as a mark; label image information and mark image information on the inspected commodity are obtained in the inspection process, and the contained commodity information half code and the commodity information offer value are extracted; finally the extracted commodity information half code and the unique and corresponding half code in the database are synthesized to work out the commodity information and a commodity information offer value, and the commodity information offer value is compared with the extracted commodity information offer value to inspect the commodity information. The printing inspecting method and device of the commodity information can effectively inspect the commodity information, can largely improve the safety of the commodity information of the inspected commodity, and is excellent in anti-fake effect.

Owner:DANDE IMAGE MASTER CO LTD ZHUHAI

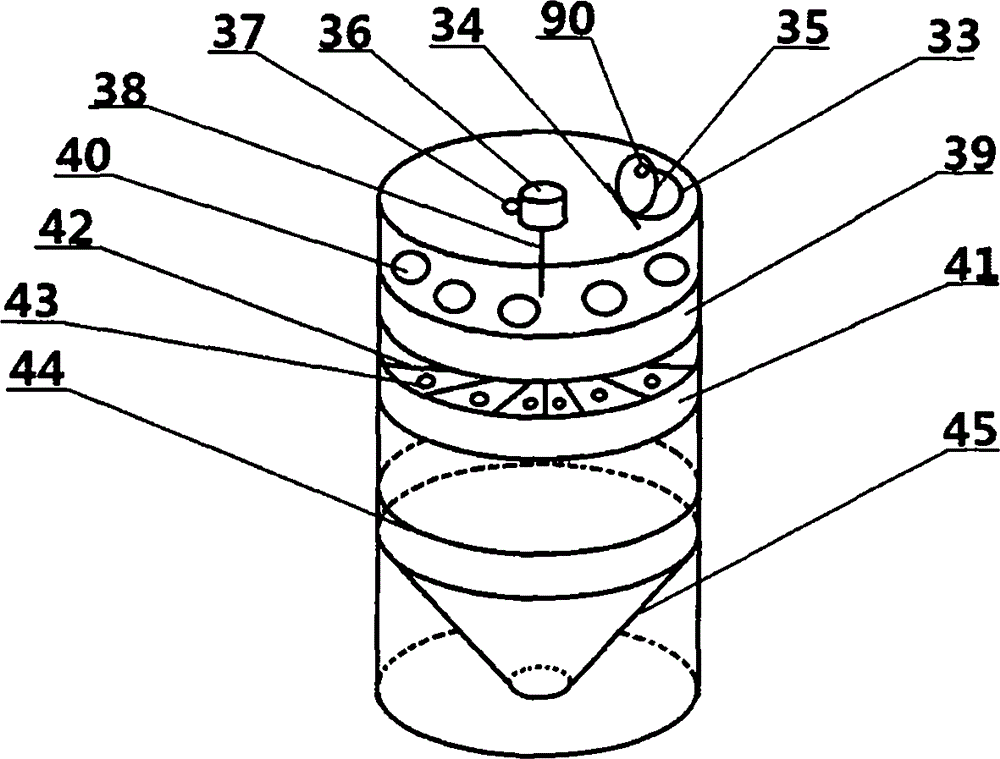

Nerve test device

InactiveCN104856674AValid inspectionShow strengthDiagnostic recording/measuringSensorsMedical staffAnatomy

The invention relates to a nerve test device, and belongs to the technical field of medical instruments. The nerve test device comprises a nerve tester main body, and is characterized in that a current variation display screen is arranged on the upper side of the nerve tester main body; a longitudinal coordinate device and a horizontal coordinate device are arranged on the current variation display screen; an image drawing device is arranged in the current variation display screen; an operation panel is arranged on the front side of the current variation display screen; a main power switch is arranged on the operation panel; an adjuster for a horizontal coordinate and a longitudinal coordinate is arranged on the right side of the main power switch; a push rod fixing plate is arranged on the right side of the nerve tester main body; a push rod connecting rod is arranged on the right side of the push rod fixing plate; a push rod is arranged on the right side of the push rod connecting rod; a diagonal bar is arranged on the lower side of the push rod connecting rod; a diagonal bar pressure reduction plate is arranged on the lower side of the diagonal bar. The nerve test device is complete in function, convenient to use and flexible in operation in nerve test, can effectively test nerves, can accurately display the intensity of nerve reaction, and reduces the burdens of medical staffs.

Owner:丰喆

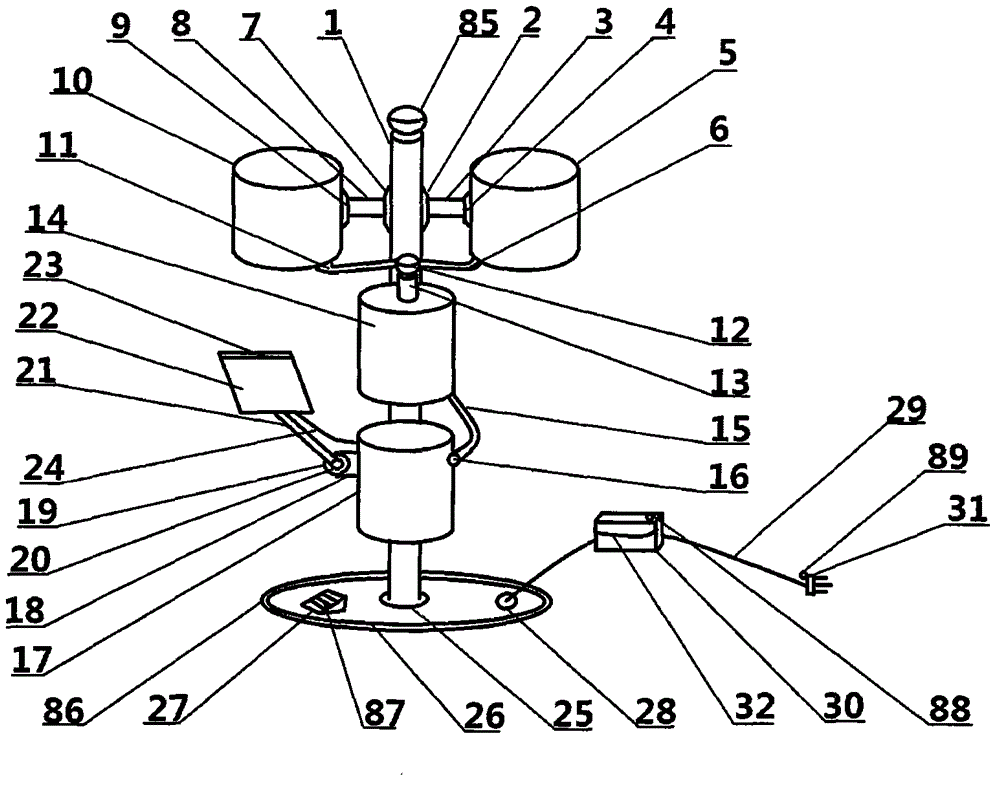

Western medicine constituent testing device

InactiveCN104792951AValid inspectionInspection is accurateTesting medicinal preparationsWestern medicineMedical equipment

The invention relates to a western medicine constituent testing device and belongs to the technical field of medical equipment. The western medicine constituent testing device comprises a main brace, wherein a water storage tank connecting rod fixing plate is arranged on the right side of the main brace, a water storage tank connecting rod is arranged on the right side of the water storage tank connecting rod fixing plate, a water storage tank fixing plate is arranged on the right side of the water storage tank connecting rod, a water storage tank is arranged on the right side of the water storage tank fixing plate, a grinding tank connecting rod fixing plate is arranged on the left side of the main brace, a grinding tank connecting rod is arranged on the left side of the grinding tank connecting rod fixing plate, a grinding tank fixing plate is arranged on the left side of the grinding tank connecting rod, a grinding tank is arranged on the left side of the grinding tank fixing plate, a base pressure relief plate is arranged on the lower side of the main brace, a base is arranged on the lower side of the base pressure relief plate, and an instrument operation foot switch is arranged on the upper left side of the base. The western medicine constituent testing device has complete functions and is convenient to use, when a medical worker performs western medicine constituent testing work, the operation is simple and convenient, time and labor are saved, and the working difficulty of the medical worker is reduced.

Owner:张新成

Method used for detecting display panel

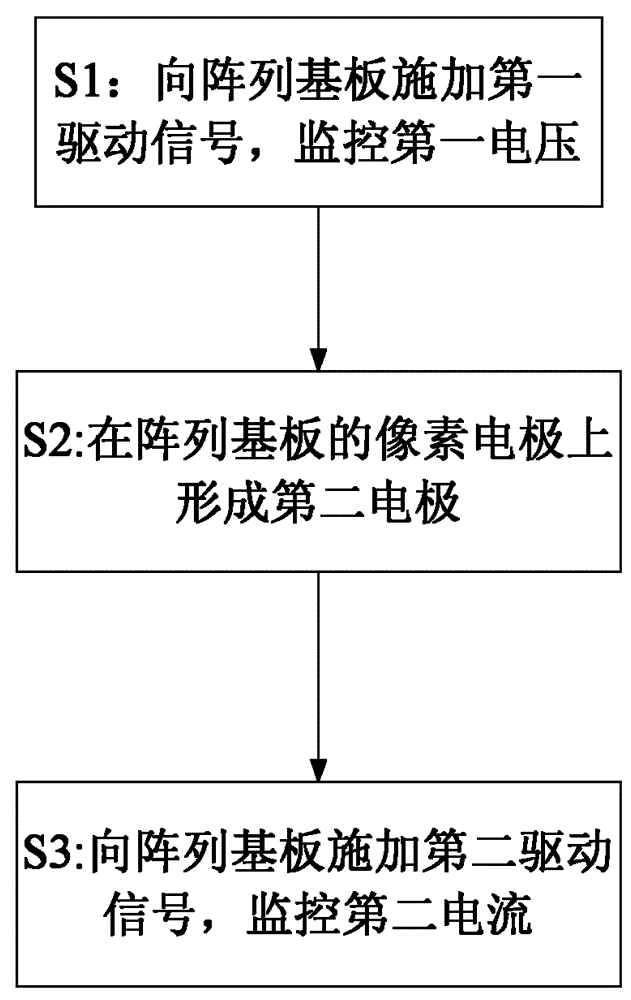

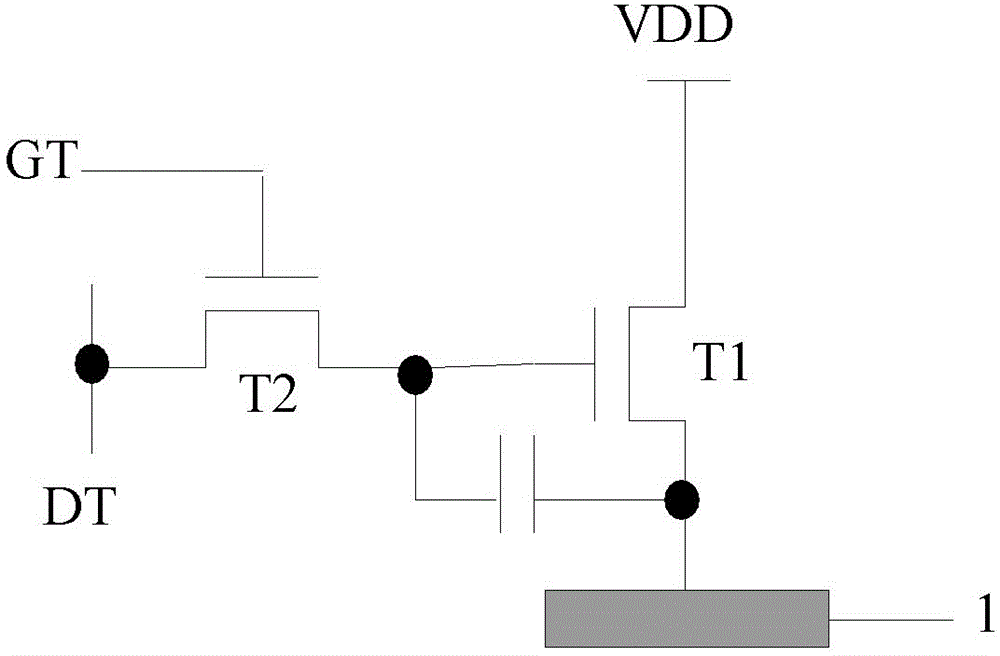

ActiveCN104809970AImprove reliabilityEfficient use ofSemiconductor/solid-state device testing/measurementStatic indicating devicesElectricityPower flow

The invention discloses a method used for detecting a display panel. The display panel comprises an array substrate used for driving an electroluminescent device, wherein the array substrate comprises pixel electrodes arranged in an array and a pixel switch array used for driving the pixel electrodes. The method comprises the following steps: S1) applying a first driving signal to the manufactured array substrate, and monitoring first voltage on the pixel arrays; S2) forming a second electrode on each pixel electrode of the array substrate; S3) applying a second driving signal to the array substrate on which the second electrode is formed, and monitoring second current which flows the second electrode, wherein each pixel electrode is one of the cathode and the anode of the electroluminescent device, and each second electrode is the other one of the cathode and the anode of the electroluminescent device. According to the method, an organic luminescent layer does not need to be manufactured, and therefore, the cost of the whole detection process is greatly lowered. Meanwhile, interference brought by new defects which may be introduced in the manufacture of the organic luminescent layer is eliminated, a detection process of the display panel is simplified, detection complexity is lowered, and the method is favorable for improving detection efficiency.

Owner:BOE TECH GRP CO LTD

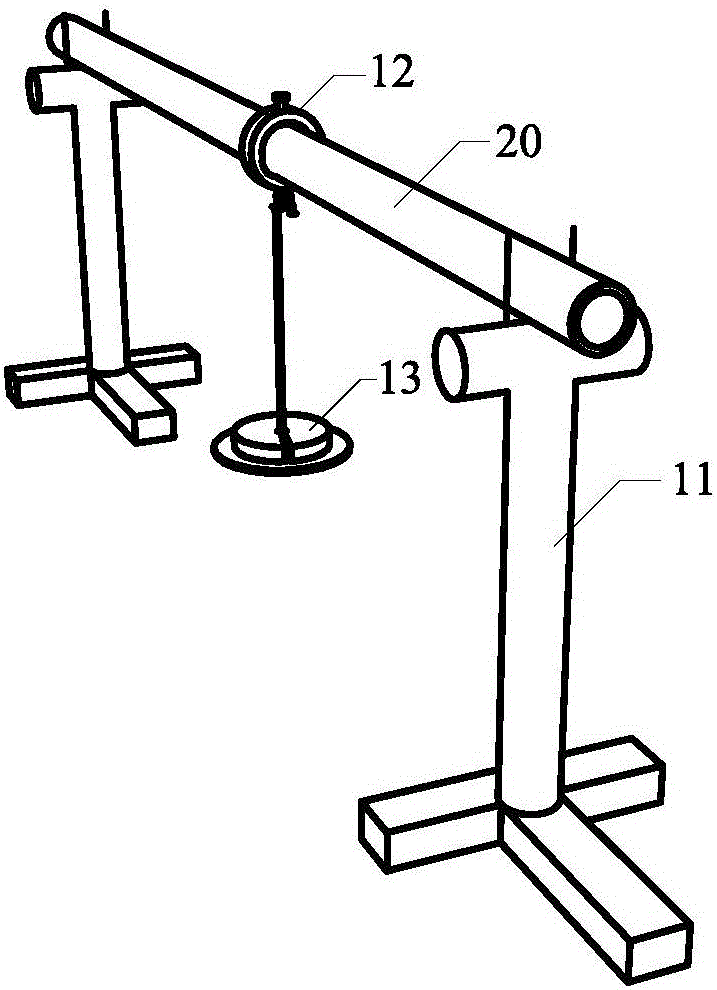

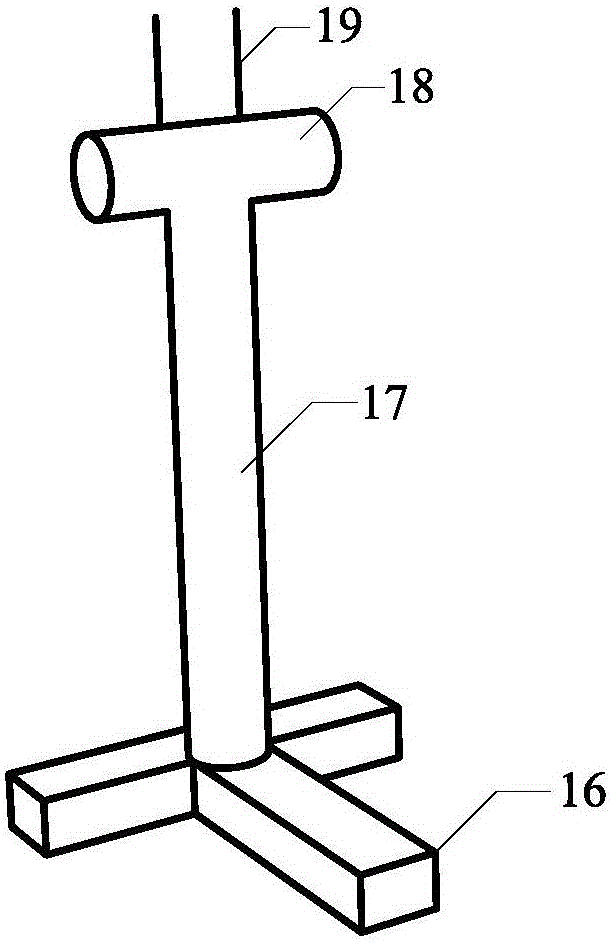

Device for comparing test performance of force measuring locking anchor pipes of tunnel and test method

ActiveCN105890829AEasy to installEasy to operateForce measurement by measuring optical property variationForce/torque/work measurement apparatus calibration/testingTest performanceGrating

The invention relates to a device for comparing the test performance of the force measuring locking anchor pipes of a tunnel and a test method. The device is convenient to install and easy to operate. The device can be used for fast verifying the test performance of the force measuring locking anchor pipe with an optical fiber grating buried therein and can be applied to the detection of the test performance of force measuring devices such as tube type force measuring devices and rod type force measuring devices. According to the technical schemes of the invention, the device of the invention includes a force measuring locking anchor pipe with an optical fiber grating buried therein, a force measuring locking anchor pipe with resistance strain gauges pasted therein, a loading ring and a supporting frame, wherein the loading ring and the supporting frame are applied to comparison. The two kinds of force measuring locking anchor pipes are arranged on the supporting frame, so that step-by-step loading tests are carried out, and the measurement results of the tests of the force measuring locking anchor pipes are compared with theoretical values, and therefore, the test performance of the two kinds of the force measuring locking anchor pipes can be analyzed and evaluated.

Owner:CHANGAN UNIV

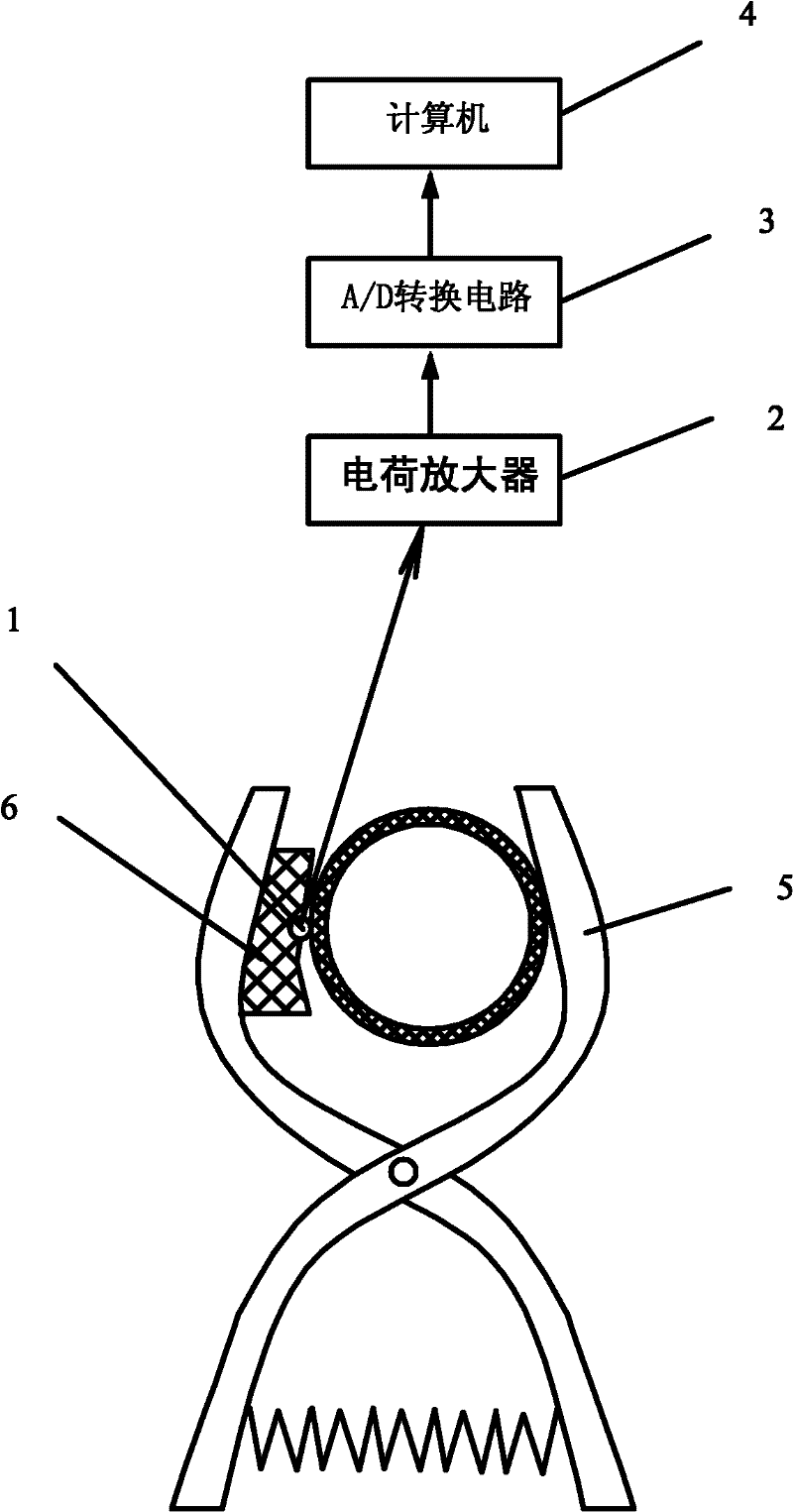

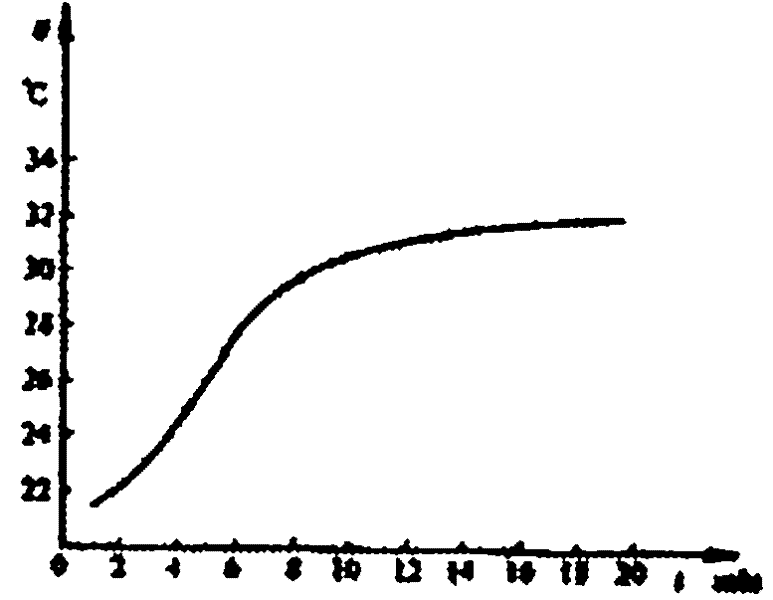

Method for inspecting water circulation system in water-cooling winding of turbonator

InactiveCN102213623AEasy to achieve test preparation conditionsEasy to realize inspection conditionsThermometers using electric/magnetic elementsUsing electrical meansStable stateRoom temperature

The invention relates to a method for inspecting a water circulation system in a water-cooling winding of a turbonator, in particular to a method for inspecting whether the water circulation system in the water-cooling winding of the turbonator is blocked or not, which is used for inspecting a circulating water system. By the method, the problem that the duration for inspection is long and the problem that test results and sensitivity are influenced seriously due to slow temperature reduction of cold water are solved. The method comprises the following steps of: 1, arranging a temperature measuring element on the outer surface of a water outlet pipe of each stator winding; 2, introducing room temperature water with the same temperature into each stator winding; 3, after the stable state of the temperature is reached, introducing high-temperature water with the same temperature into each stator winding, and recording the process of temperature variation on the outer surfaces of the water outlet pipes simultaneously; and 4, calculating the speed of the temperature variation of the outer surface of each water outlet pipe, and for the water outlet pipe of which the temperature variation speed is over 10 percent less than the average temperature variation speed, determining that the water pipe of which the inside is blocked.

Owner:STATE GRID CORP OF CHINA +1

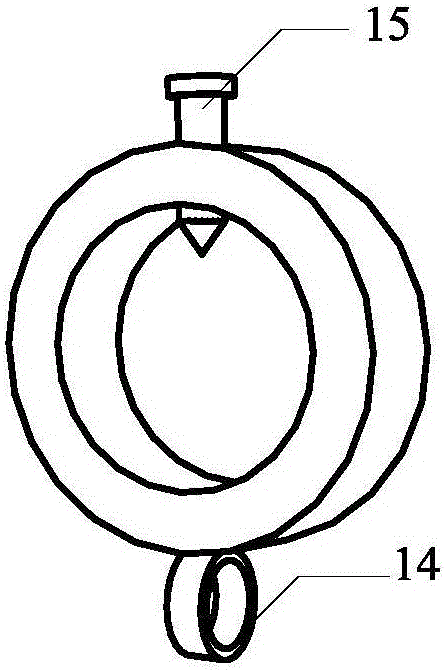

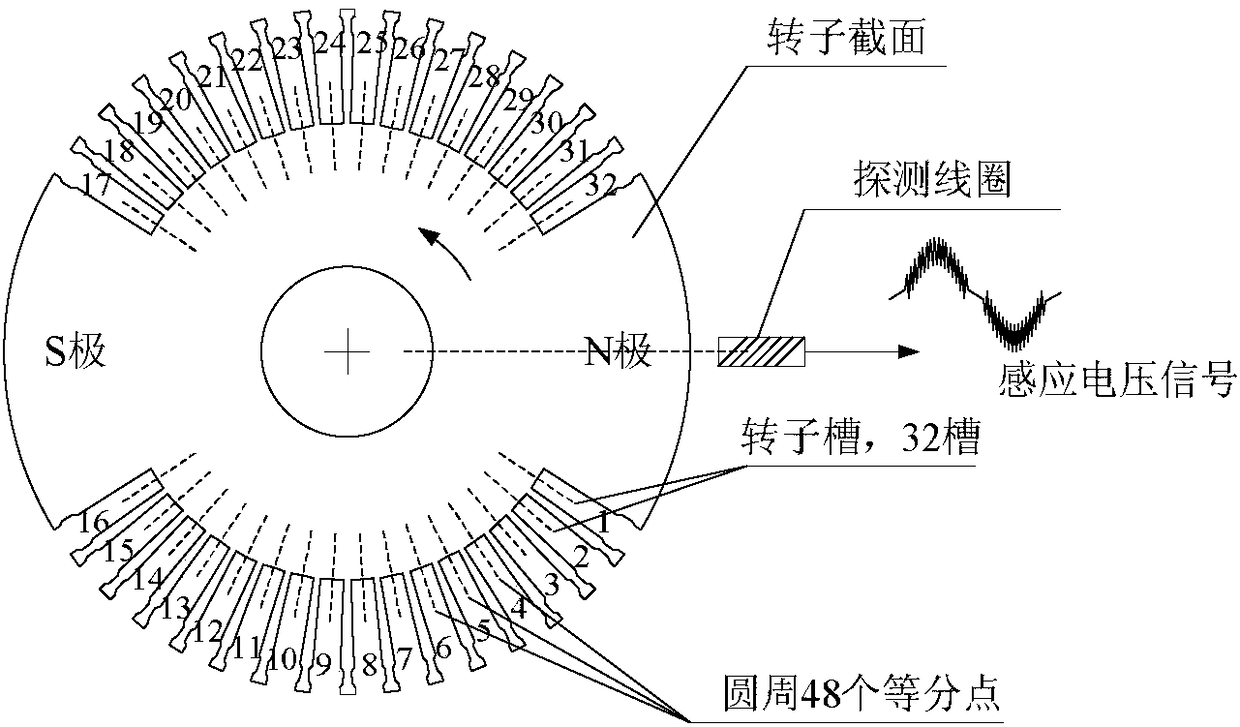

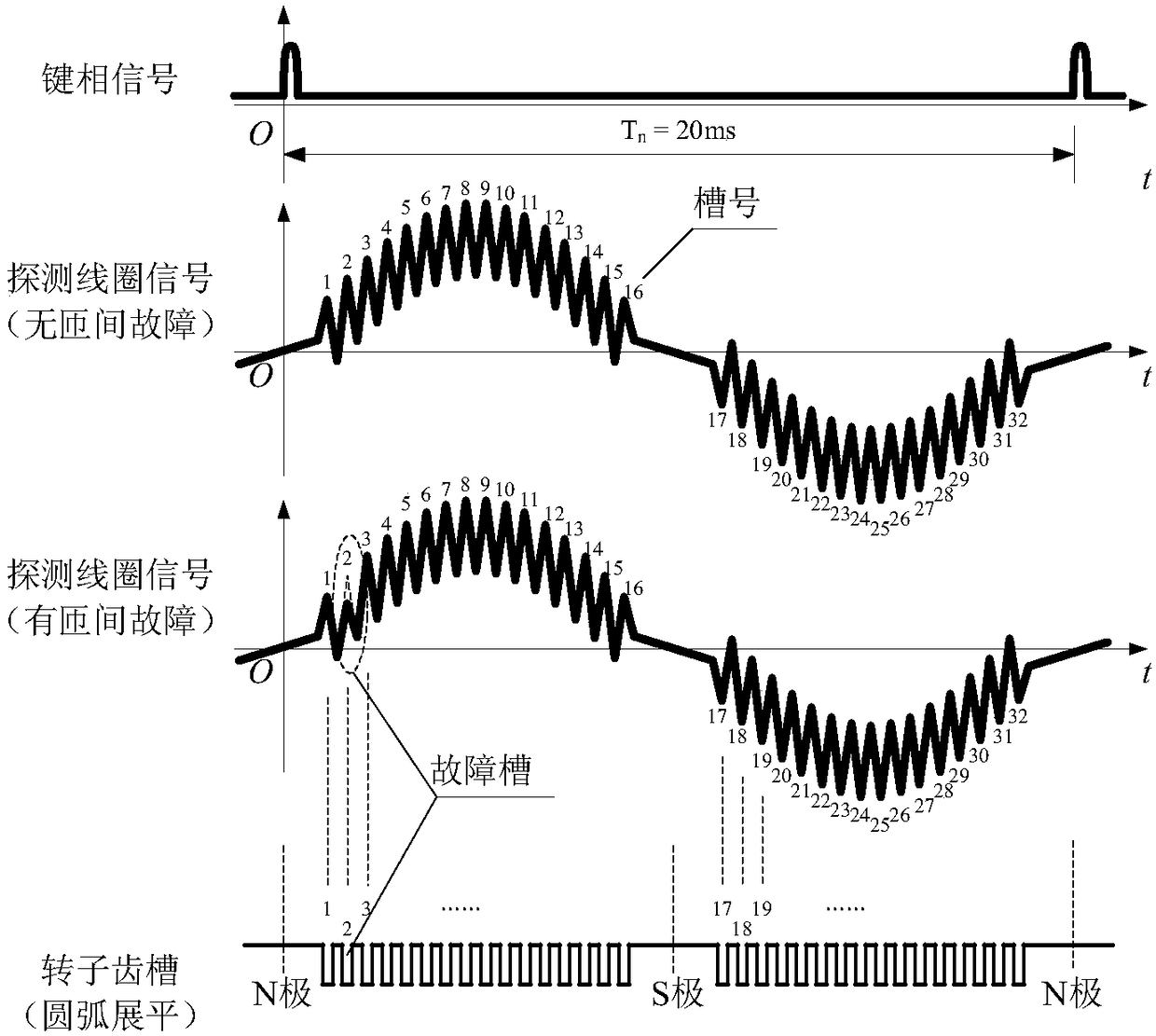

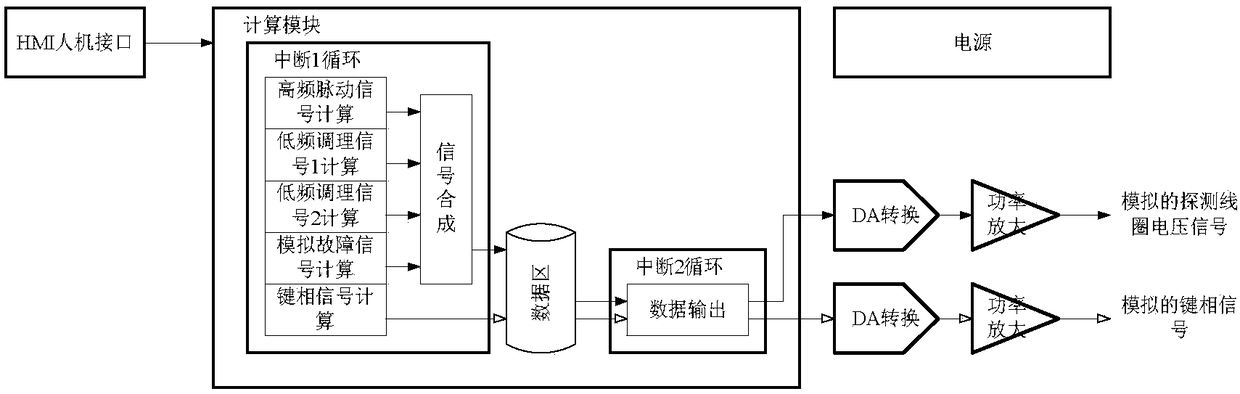

Test device and method for generator rotor winding turn-to-turn short-circuit fault monitoring device

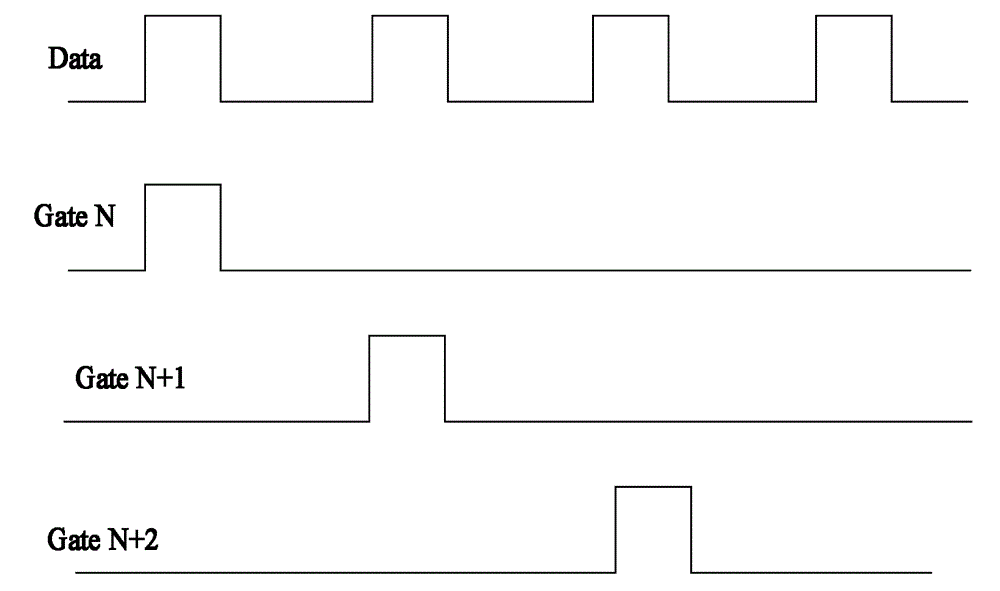

ActiveCN108732522AStrengthen the product inspection linkImprove product qualityElectrical measurementsHuman–machine interfaceTest fixture

The invention discloses a test device for a generator rotor winding turn-to-turn short-circuit fault monitoring device. The test device comprises an HMI human-machine interface module, a calculation module, two DA conversion modules, two signal amplification output modules and a power supply module. The invention further discloses a test method for the generator rotor winding turn-to-turn short-circuit fault monitoring device. The test method comprises the steps of: firstly, setting fixed value parameters of output waveforms; secondly, calculating simulated key phase signal data and detectioncoil voltage data; thirdly, transmitting a simulated key phase signal and a simulated detection coil voltage signal to a tested rotor winding turn-to-turn fault monitoring device after DA conversion and amplification; and finally, checking whether signal sampling, fault feature calculation and logical judgment results of the tested rotor winding turn-to-turn fault monitoring device are correct. The test device and the test method can generate voltage waveforms similar to voltage waveforms actually measured by means of a field detection coil, simulate normal waveforms and fault waveforms, can verify whether the signal sampling, fault feature calculation and logic judgment of the monitoring device are correct in advance before the installation of equipment.

Owner:NR ELECTRIC CO LTD +1

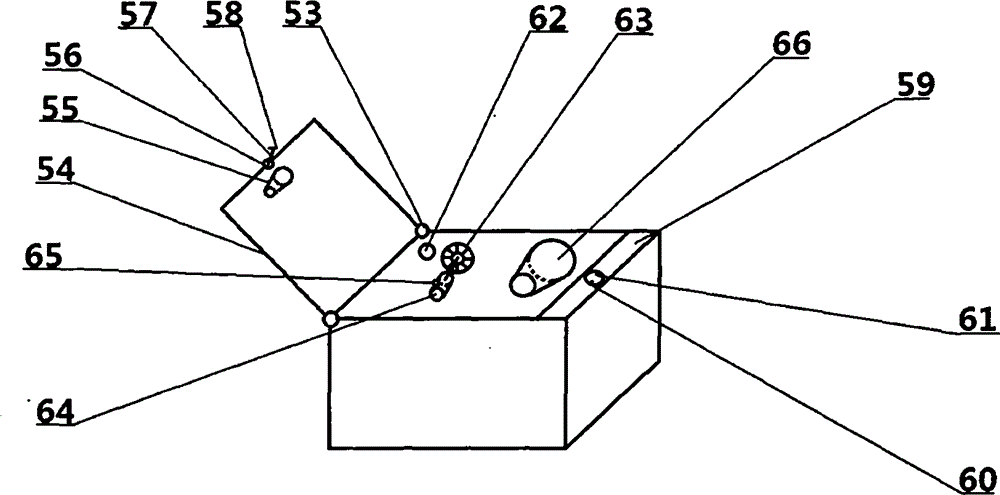

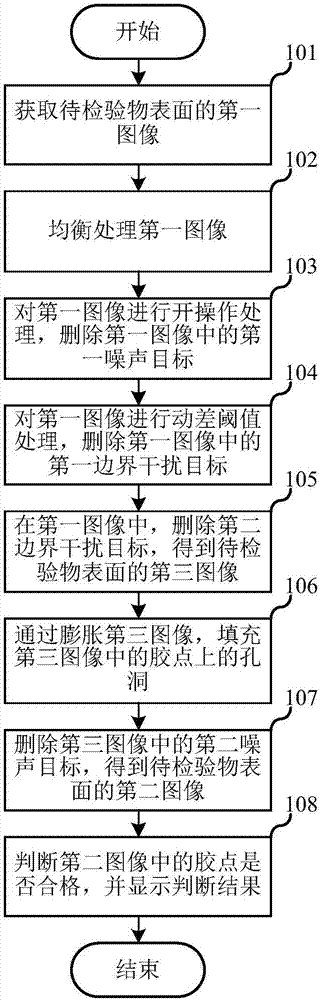

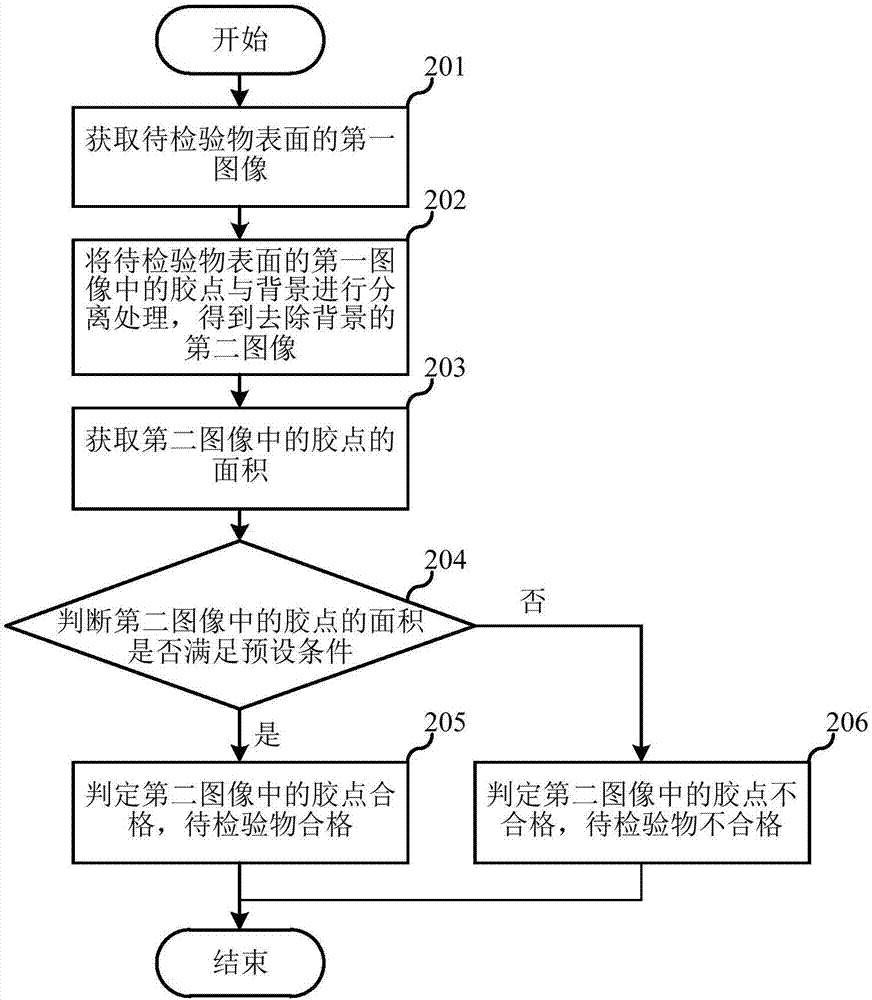

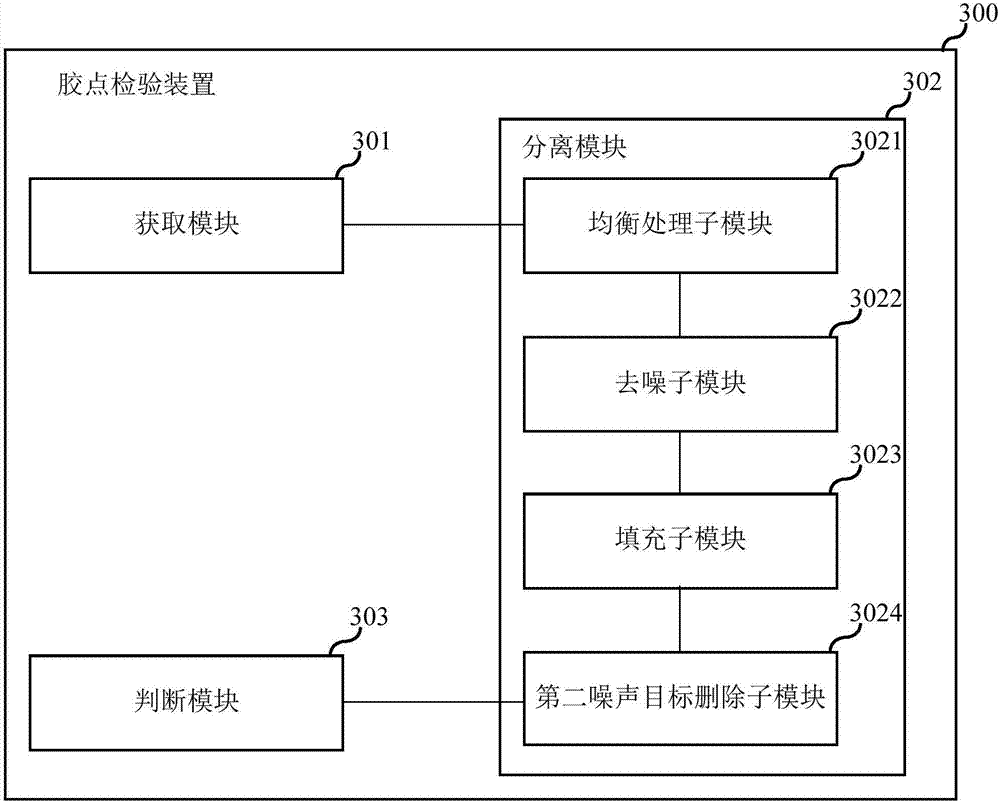

Glue point inspection method and device

InactiveCN107358597AAvoid artificialAvoid Manual InspectionImage enhancementImage analysisImaging processingInspection method

The invention relates to the field of image processing, and discloses a glue point inspection method and device. The glue point inspection method comprises the steps of acquiring a first image of the surface of an object to be inspected; separating a glue point in the first image of the surface of the object to be inspected from the background to obtain a second image with the background being removed; and judging whether the glue point in the second image is qualified or not, and displaying a judgment result. The embodiment of the invention further provides a glue point inspection device. Whether the glue point at the surface of the object to be inspected is qualified or not can be effectively inspected according to the invention. Meanwhile, the labor cost can be saved.

Owner:上海视马艾智能科技有限公司

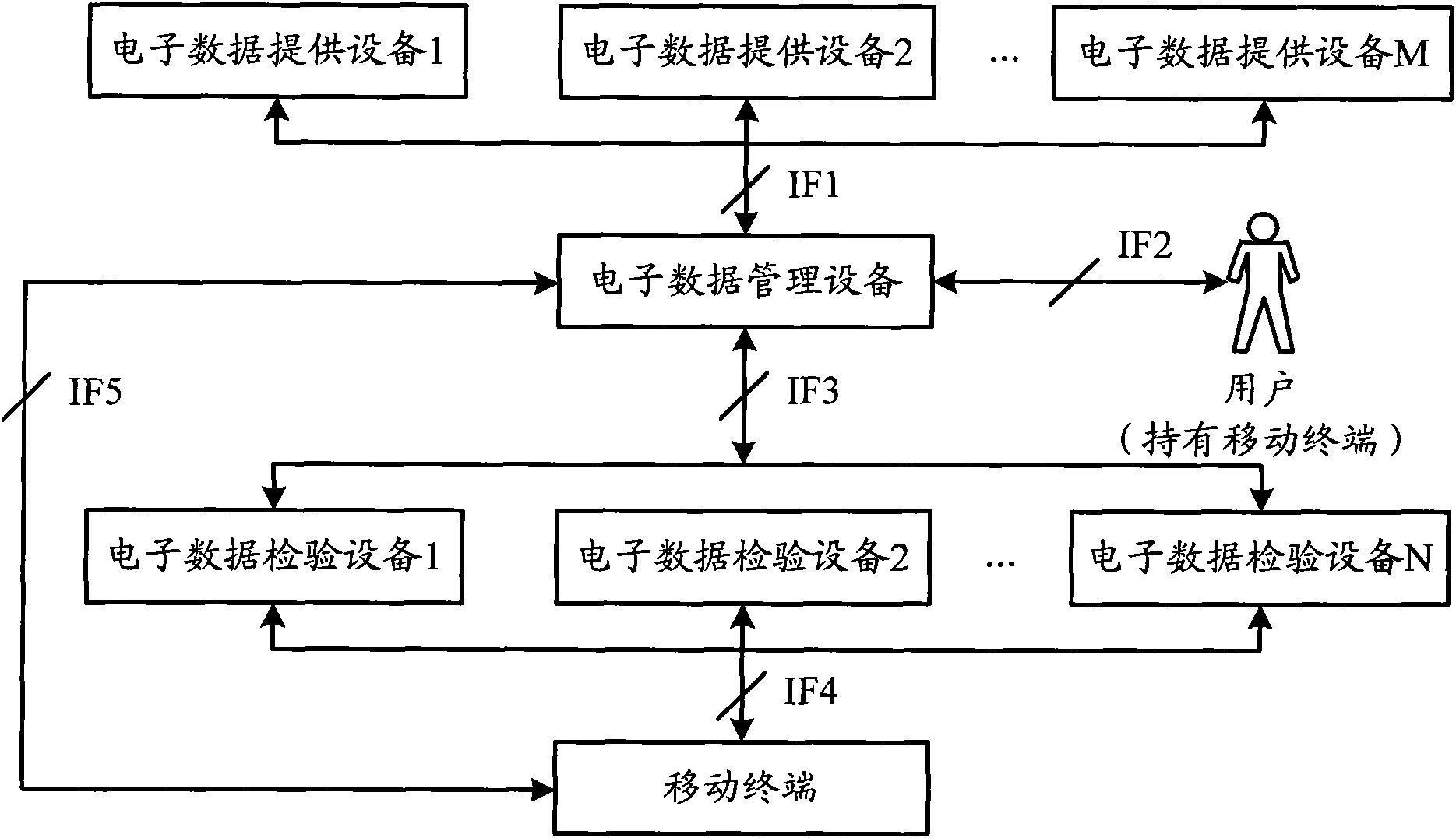

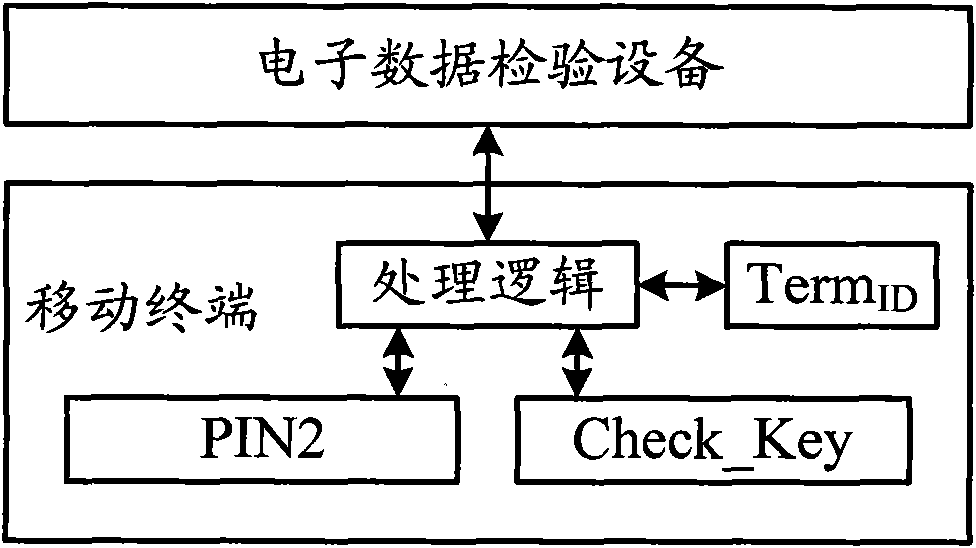

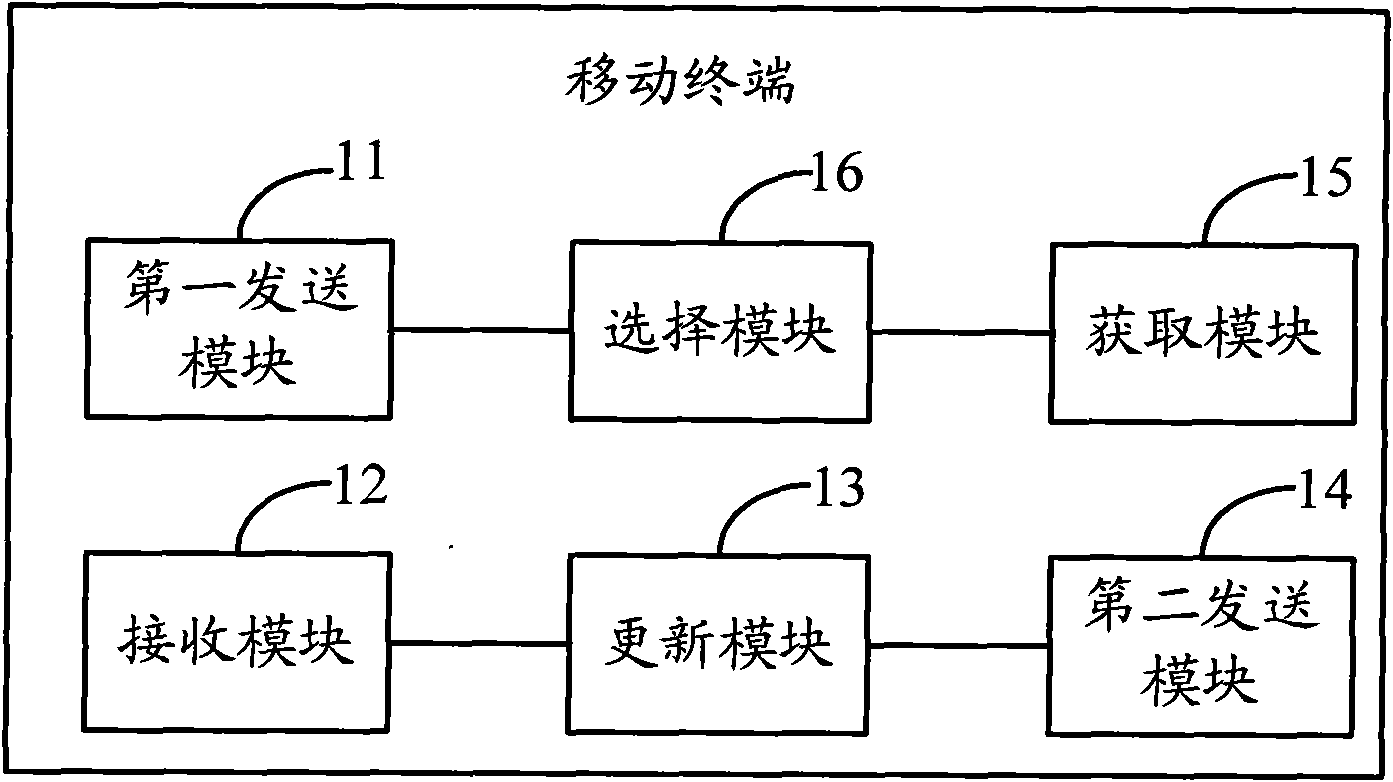

Method, system and equipment for testing electronic data

ActiveCN102595402AInspection process safetyValid inspectionSecurity arrangementComputer scienceElectronic data

The invention discloses a method, a system and equipment for testing electronic data. The method comprises the following steps that: a mobile terminal sends a testing request of electronic data to electronic data management equipment; when the electronic data passes the test, the electronic data management equipment updates state information of the electronic data and sends a testing result of the electronic data to the mobile terminal; and the mobile terminal updates the state information of the electronic data according to the testing result of the electronic data and sends the updated state information to the electronic data testing equipment. In the embodiment of the invention, the testing request of the electronic data is sent to the electronic data management equipment by the mobile terminal so as to complete testing the electronic data; the electronic data testing equipment does not need to be connected with the electronic data management equipment; the method, the system and the equipment are simple to implement; and the electronic data testing process is safe and effective.

Owner:CHINA MOBILE COMM GRP CO LTD

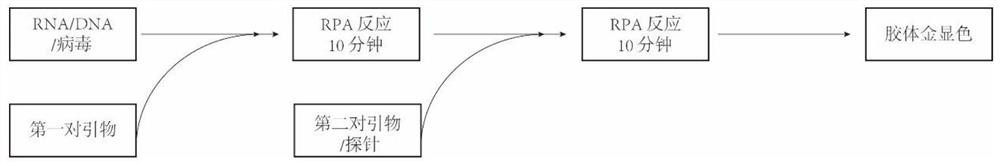

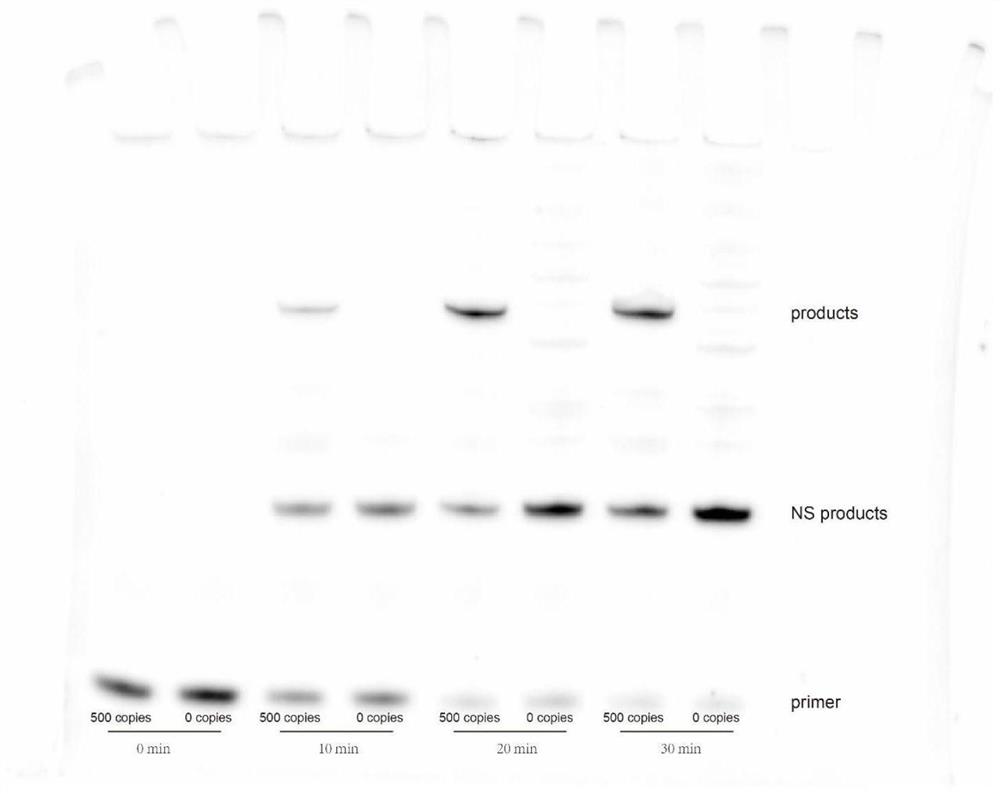

Nested recombinase-polymerase amplification method and application thereof

PendingCN112481358AQuick checkReduced detection operation stepsMicrobiological testing/measurementNucleic acid detectionRecombinase Polymerase Amplification

The invention relates to a rapid and high-sensitivity nested recombinase polymerase amplification detection method, a related nucleic acid rapid detection method and a nested recombinase polymerase amplification detection kit. According to the present invention, nucleic acid can be rapidly detected with high sensitivity, two reaction reagents do not need to be prepared during the reaction process,and the reaction product capable of carrying out sensitive detection can be obtained through the direct reaction, such that the nucleic acid detection operation steps are substantially simplified, the operation complexity is reduced, and the sensitivity is improved.

Owner:TSINGHUA UNIV

V-shaped cutting deviation detecting method of circuit board

ActiveCN102721384AReduce the difficulty of inspectionThe detection method is simpleMeasurement devicesShort circuitEngineering

The invention relates to a V-shaped cutting deviation detecting method of a circuit board. According to the V-shaped cutting deviation detecting method, a V-CUT deviation detecting hole drilling procedure is added to the hole drilling procedure in hole drilling process of the circuit board; and the V-CUT deviation detecting hole drilling procedure is arranged as follows: one or more V-CUT deviation detecting holes are drilled at each of two ends of each V-CUT line which is proposed to be cut in V shape and outside a formation line of a base plate of the circuit board before or after drilling the hole at the first time; and after the circuit board is formed, a V-CUT groove formed after cutting in the V shape is detected to determine whether the V-CUT groove is cut through the centre of circles of the V-CUT deviation detecting holes at two ends of the V-CUT line, if so, the cutting in V shape can be determined that the deviation not occurred thereto, and if not so, the cutting in V shape can be determined that the deviation occurred thereto. The diameter of a V-CUT deviation preventing hole is 0.8 to 1.0 millimeters. The distance from the V-CUT deviation detecting hole to the formation line is 1 to 2 millimeters. With the adoption of the method provided by the invention, the difficulty in V-CUT detecting can be reduced, the detecting timeliness can be improved, the short circuit phenomenon caused by non-removed V-CUT line can be prevented, and the V-CUT precision can be improved as well.

Owner:SHENGHUA ELECTRONICS HUIYANG

Turbine mechanical fly ball laser sealing welding seam inspection method

InactiveCN103808467AQuick testValid inspectionDetection of fluid at leakage pointWeld seamSolubility

The invention relates to a turbine mechanical fly ball laser sealing welding seam inspection method which is characterized by including the following steps: 1) melting solid wax into liquid solvent and keeping the liquid phase state of the solvent; b) completely immersing a mechanical fly ball finishing sealing welding into the liquid solvent with the immersing time no less than 3 minutes; c) checking whether bubbles are spilled from a mechanical fly ball sealing welding seam. According to the method, the mechanical fly ball is completely immersed into the molten wax solvent to be heated to enable the temperature of gas in a fly ball closed cavity to increase, and the welding seam can be inspected by building the pressure difference of the high pressure in the fly ball closed cavity and the external constant (low) temperature. When the welding seam has defects (not sealed), the internal gas escapes from the defect portion under the pressure difference. Due to the fact that the solubility of the gas in the liquid wax solvent is low, the gas escaping from the closed cavity cannot escape from the wax solvent under the effect of the surface tension of the wax solvent, and the gas are in the bubble shape on the surface of the welding seam defect.

Owner:HANGZHOU STEAM TURBINE

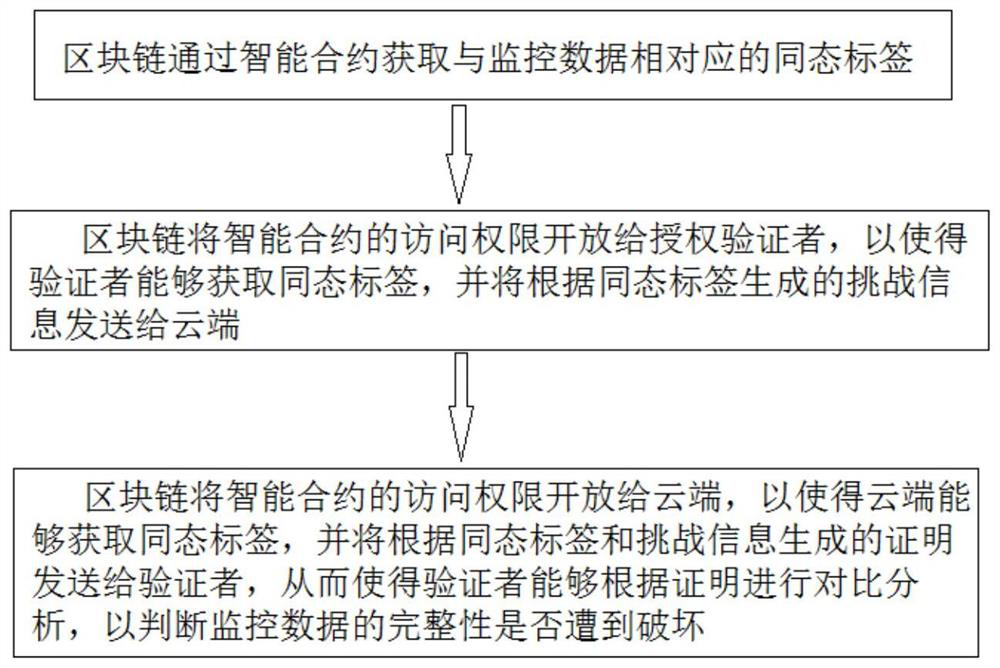

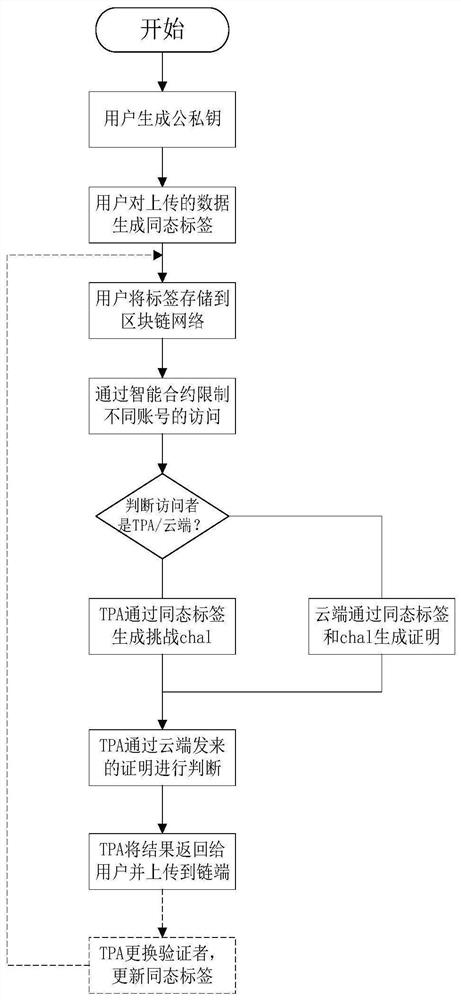

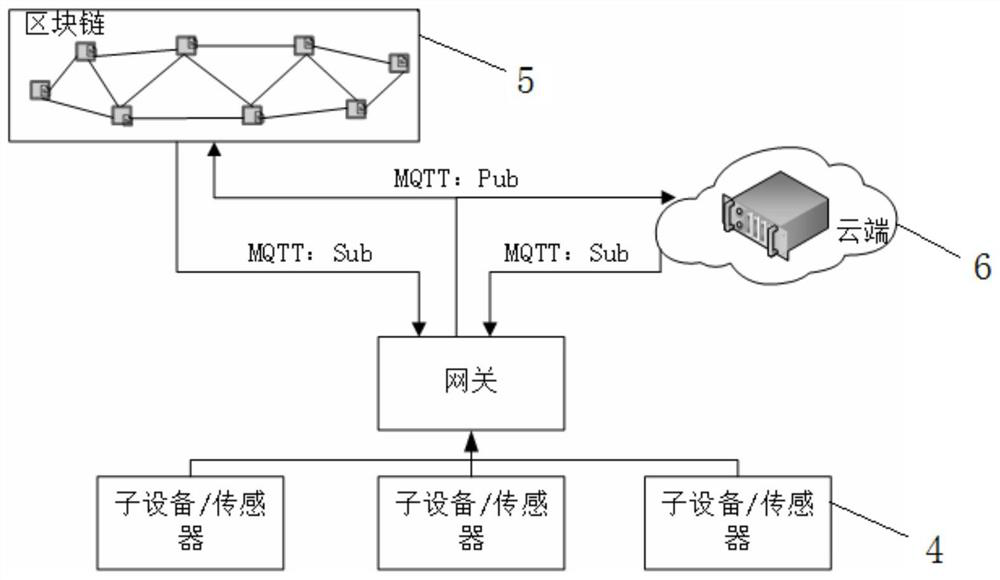

Industrial Internet data security monitoring method and system based on block chain

ActiveCN111711627AJudgment integrityAvoid key exchangeCommunication with homomorphic encryptionThe InternetMonitoring system

The embodiment of the invention provides an industrial Internet data security monitoring method based on a block chain. The method comprises the following steps that the block chain acquires a homomorphic tag corresponding to monitoring data through an intelligent contract; the block chain opens the access permission of the intelligent contract to an authorization verifier, so that the verifier can obtain the homomorphic tag and send challenge information generated according to the homomorphic tag to the cloud; the block chain opens the access permission of the intelligent contract to the cloud, the cloud can acquire the homomorphic tag and send the certificate generated according to the homomorphic tag and the challenge information to the verifier, so that the verifier can perform comparative analysis according to the certificate to judge whether the integrity of the monitoring data is damaged or not, and a reliable data basis is provided for industrial Internet data security monitoring. The embodiment of the invention further provides an industrial Internet data security monitoring system based on the block chain. According to the invention, reliable protection can be provided for data security of the industrial Internet.

Owner:HUNAN TIAN HE GUO YUN TECH CO LTD

Board surface roughness inspection method and device

ActiveCN103308010AQuick testCombination structure is simpleUsing fluid meansSurface roughnessElectrical and Electronics engineering

The invention discloses a board surface roughness inspection method and a board surface roughness inspection device. The method comprises the steps of film forming, film culturing and evaluation, wherein whether a roughening effect is qualified or not is judged according to the film culturing time of a liquid film on a board surface. The inspection method and the inspection device with a simple structure are combined, are simple, reliable and efficient and fast in inspection, and are suitable for industrial online batch full inspection under the condition of not damage.

Owner:GUANGDONG SHENGYI SCI TECH

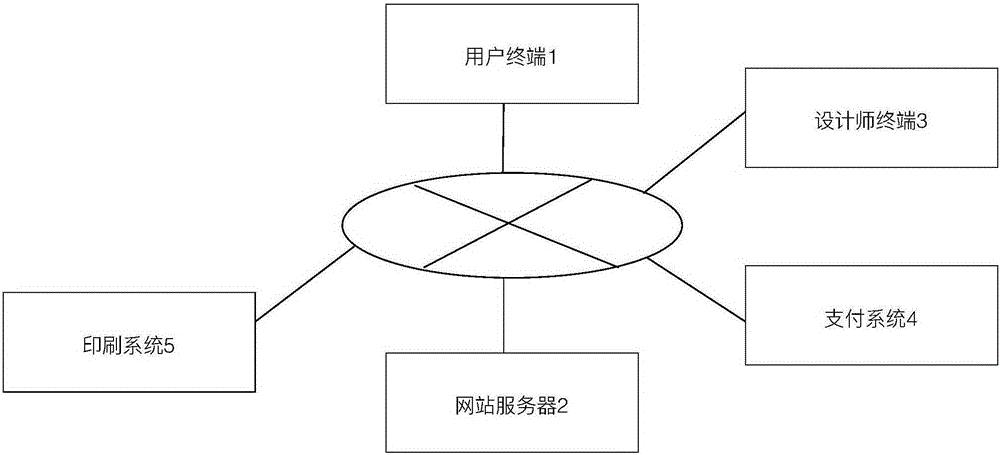

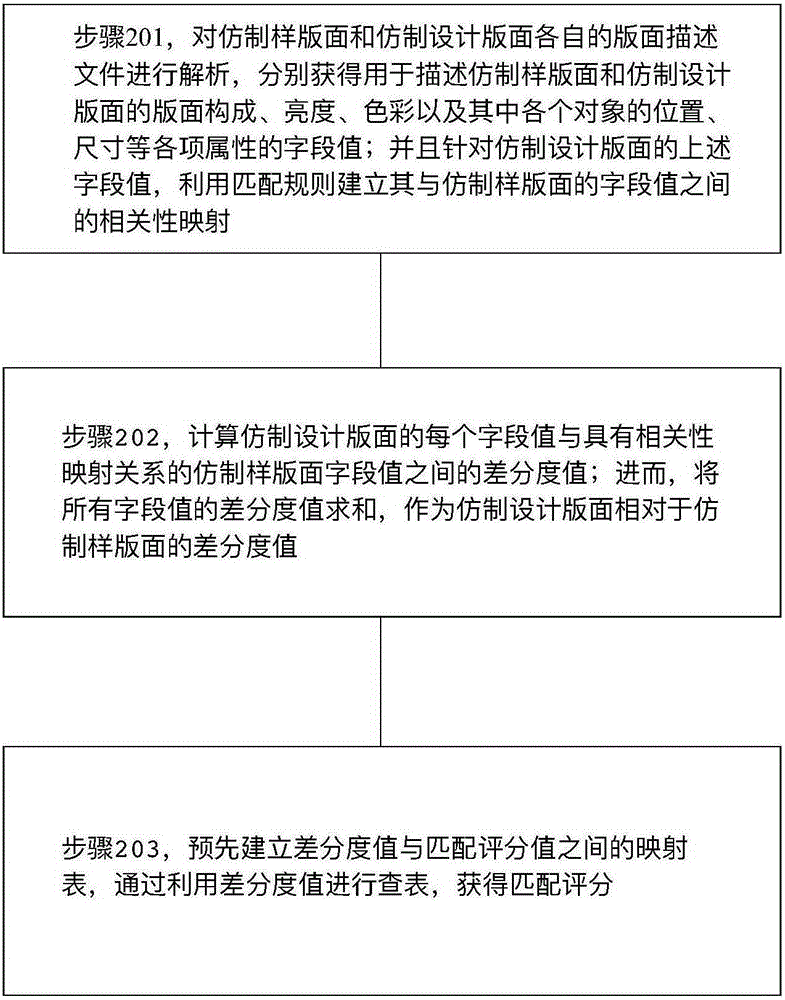

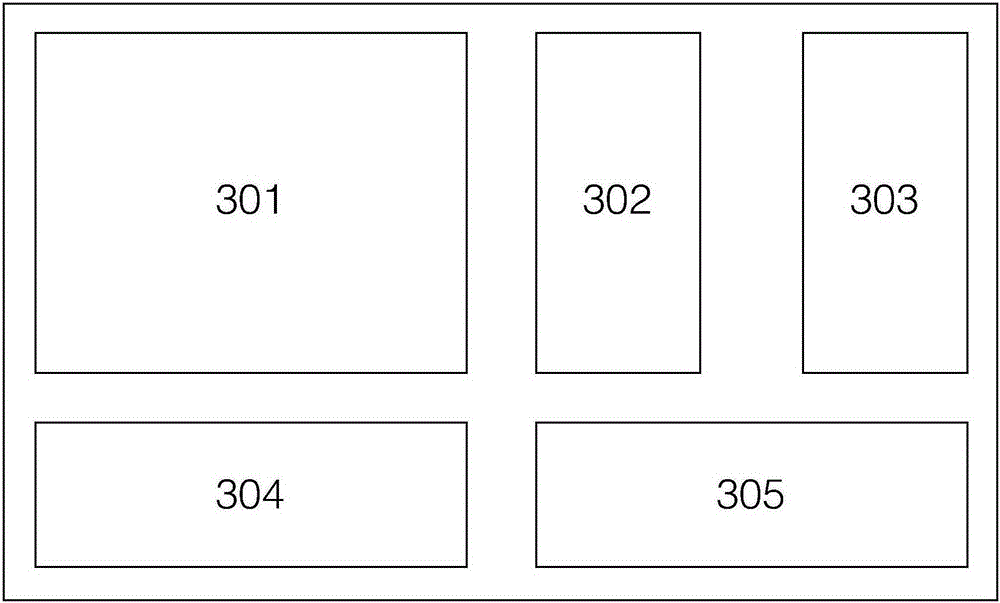

Fuzzy matching algorithm based printed material imitation design method and system

ActiveCN105279141ACompromise qualityQuality assuranceOffice automationSpecial data processing applicationsDesign methodsIndustrial engineering

The present invention provides a fuzzy matching algorithm based printed material imitation design method and system. According to the method provided by the present invention, fuzzy matching is performed between an imitation design layout and an imitation pattern layout, so as to obtain a differential value between the layouts above, and the matching is scored according to a mapping of the differential value. The method and system provided by the present invention are applicable to not only querying the matching score as a reference during a process of a background designer executing imitation design, but also performing verification on an imitation design layout provided by the background designer according to the matching score by an on-line printed material customized service website, for example, only when the imitation design layout reaches or is higher than a predetermined matching score, the imitation design layout can be considered as an eligible imitation design layout by the website and provided for a user.

Owner:武汉墨纸科技有限公司

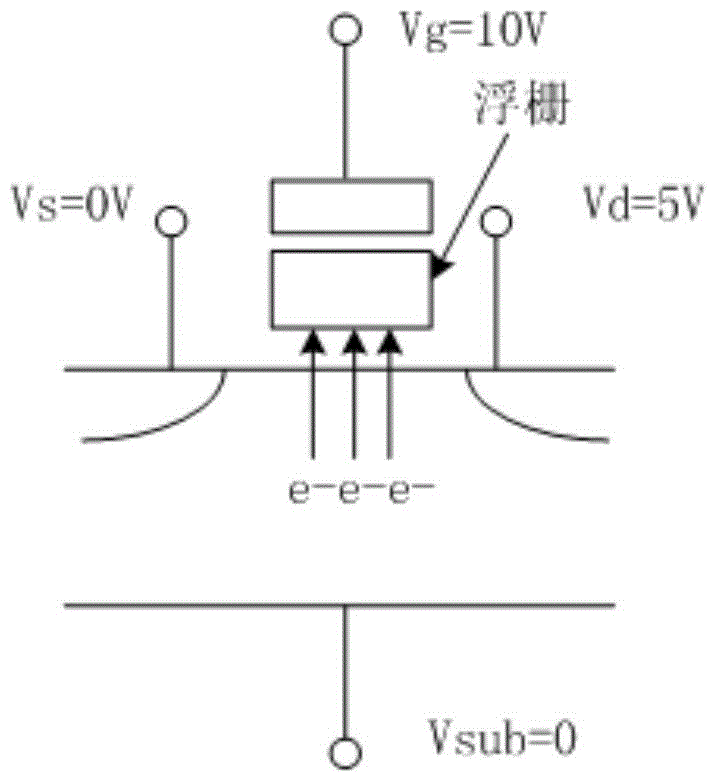

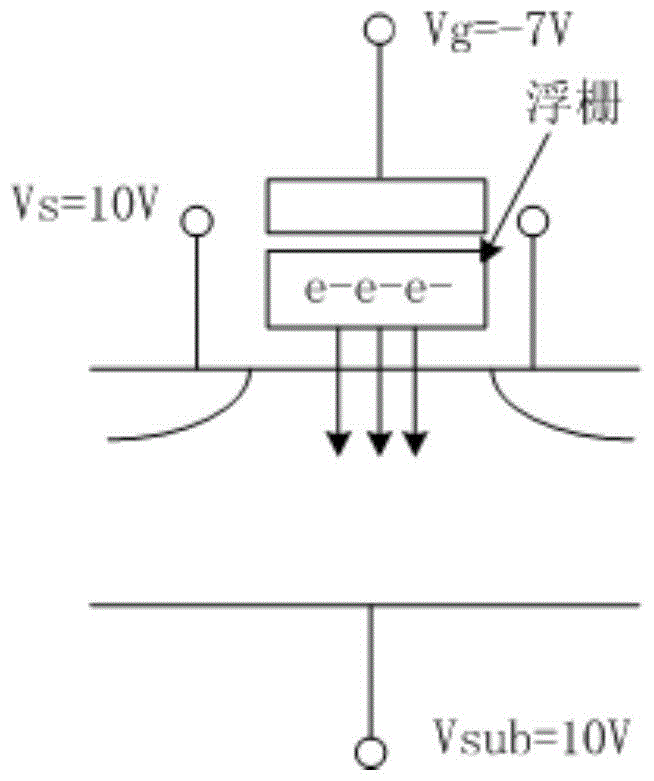

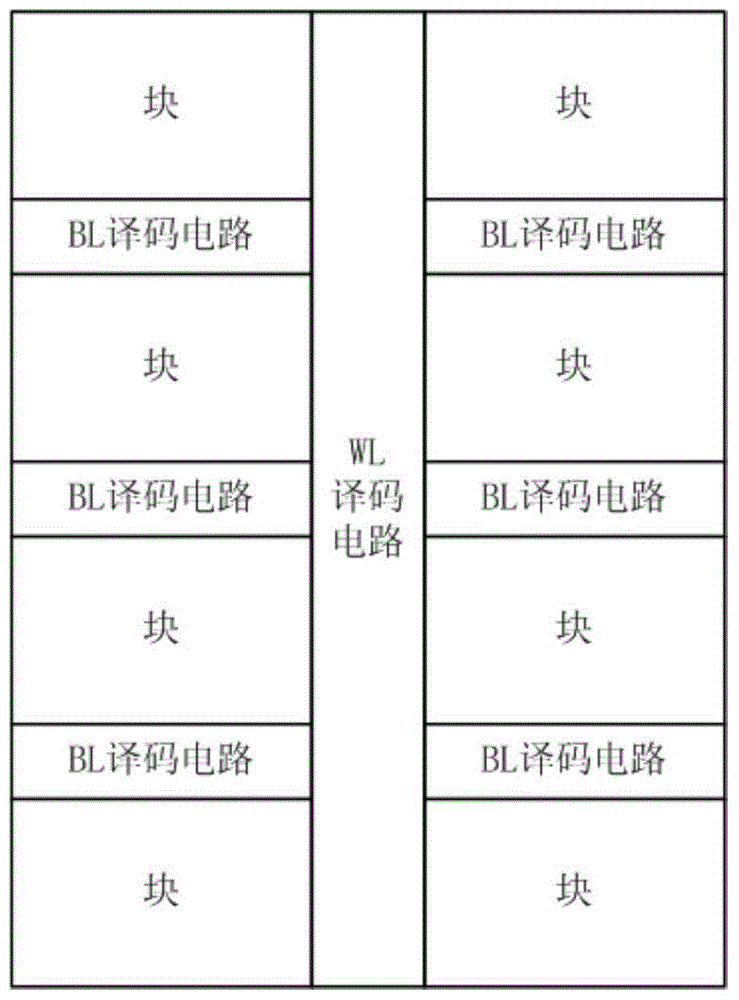

Method and device for checking disturbed nonvolatile storage unit

The invention provides a method for checking a disturbed nonvolatile storage unit. The method is applied to the nonvolatile storage unit and comprises the following steps: a) setting a count value of a counter as a preset value; b) receiving an erase block instruction, wherein the erase block instruction comprises address information of a corresponding erase block; c) executing erase operation according to the address information of the corresponding erase block; d) according to the current count value of the counter, determining a corresponding disturb block in the same big block with the corresponding erase block; e) carrying out repair operation on the corresponding disturb block; and f) adding the count value of the counter with one and returning to the step b). According to the method and the device disclosed by the invention, not only can the time be saved, but also the disturbed storage unit can be checked and repaired timely and effectively; and meanwhile, the burning time and cost of a chip after tape-out can be greatly reduced, thereby pushing a product to a customer timely.

Owner:XTX TECH INC

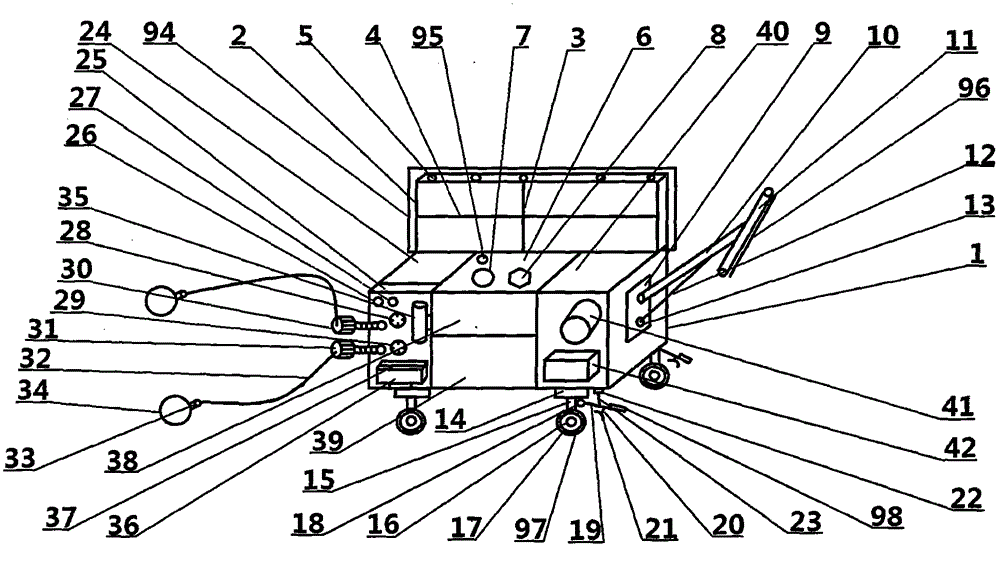

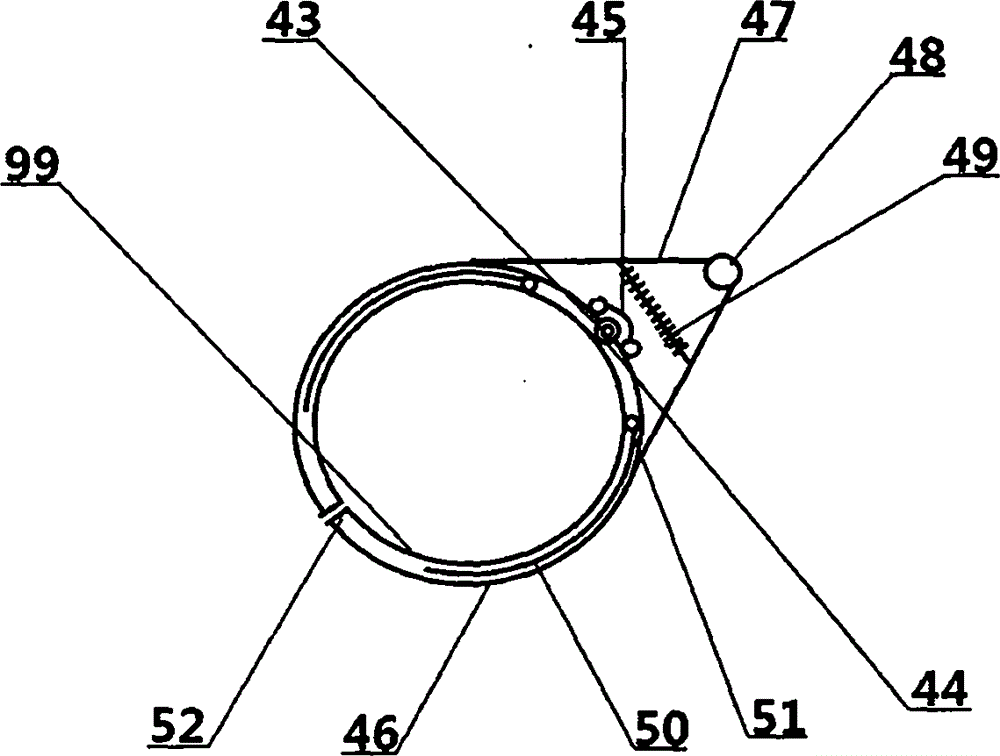

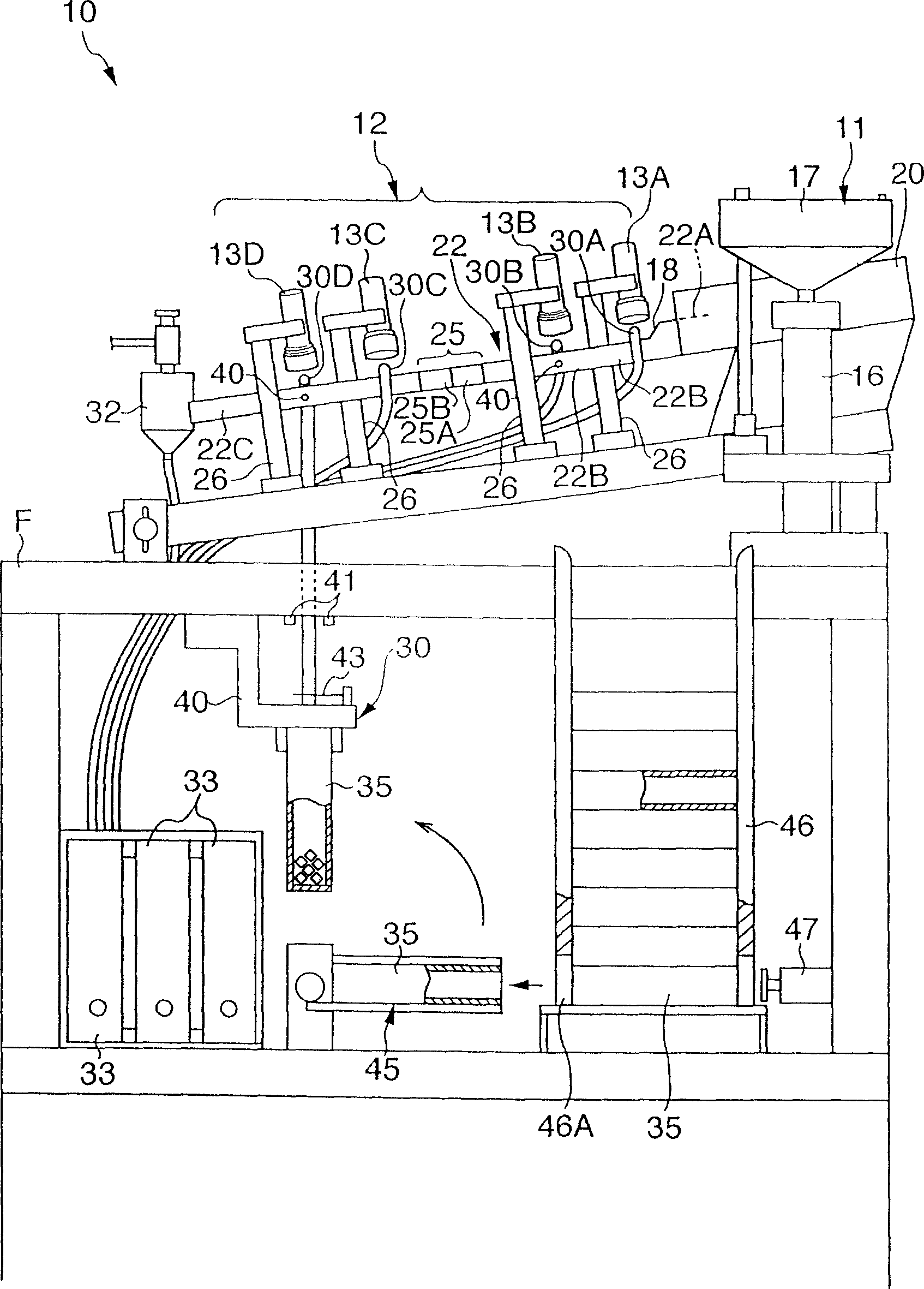

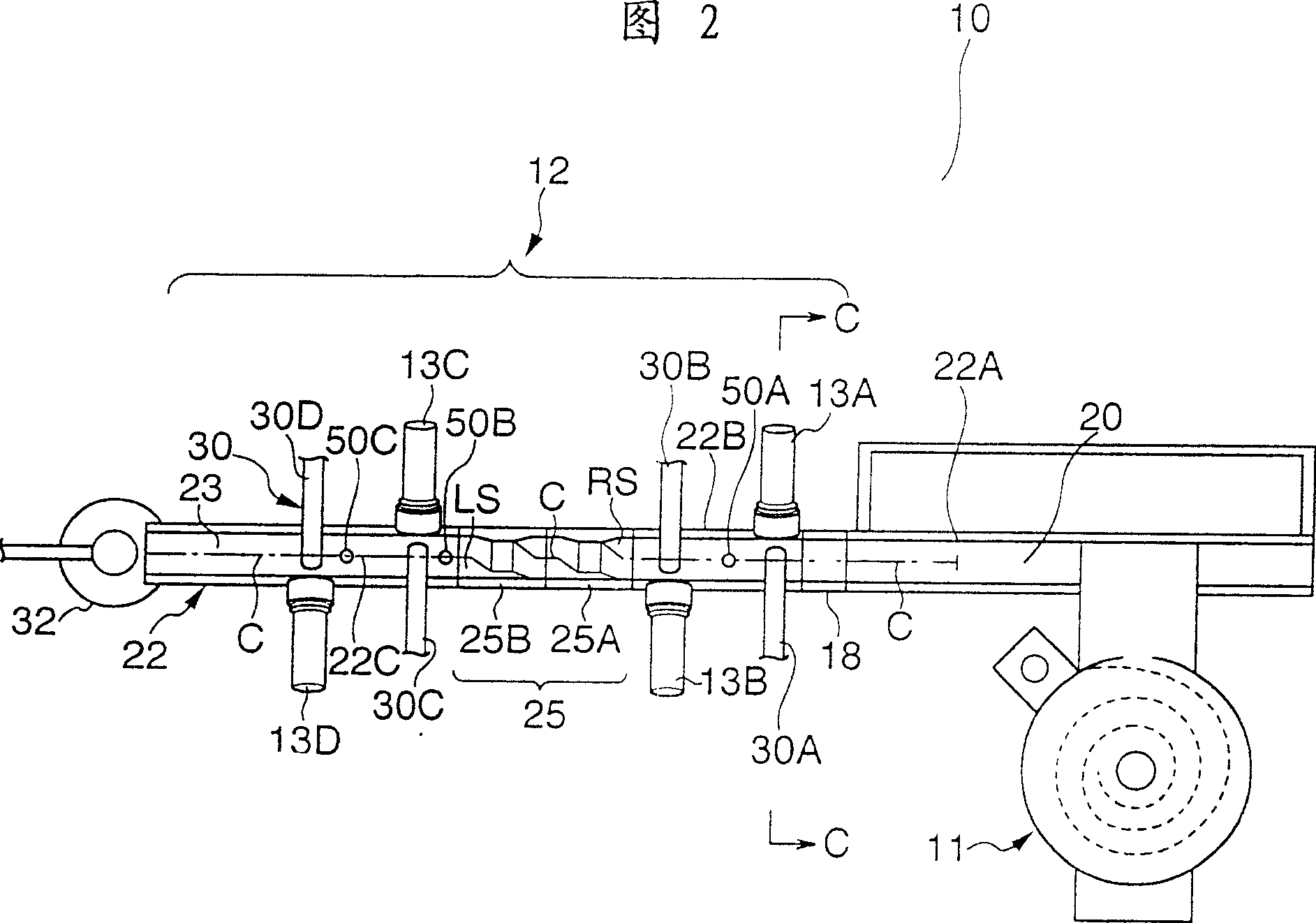

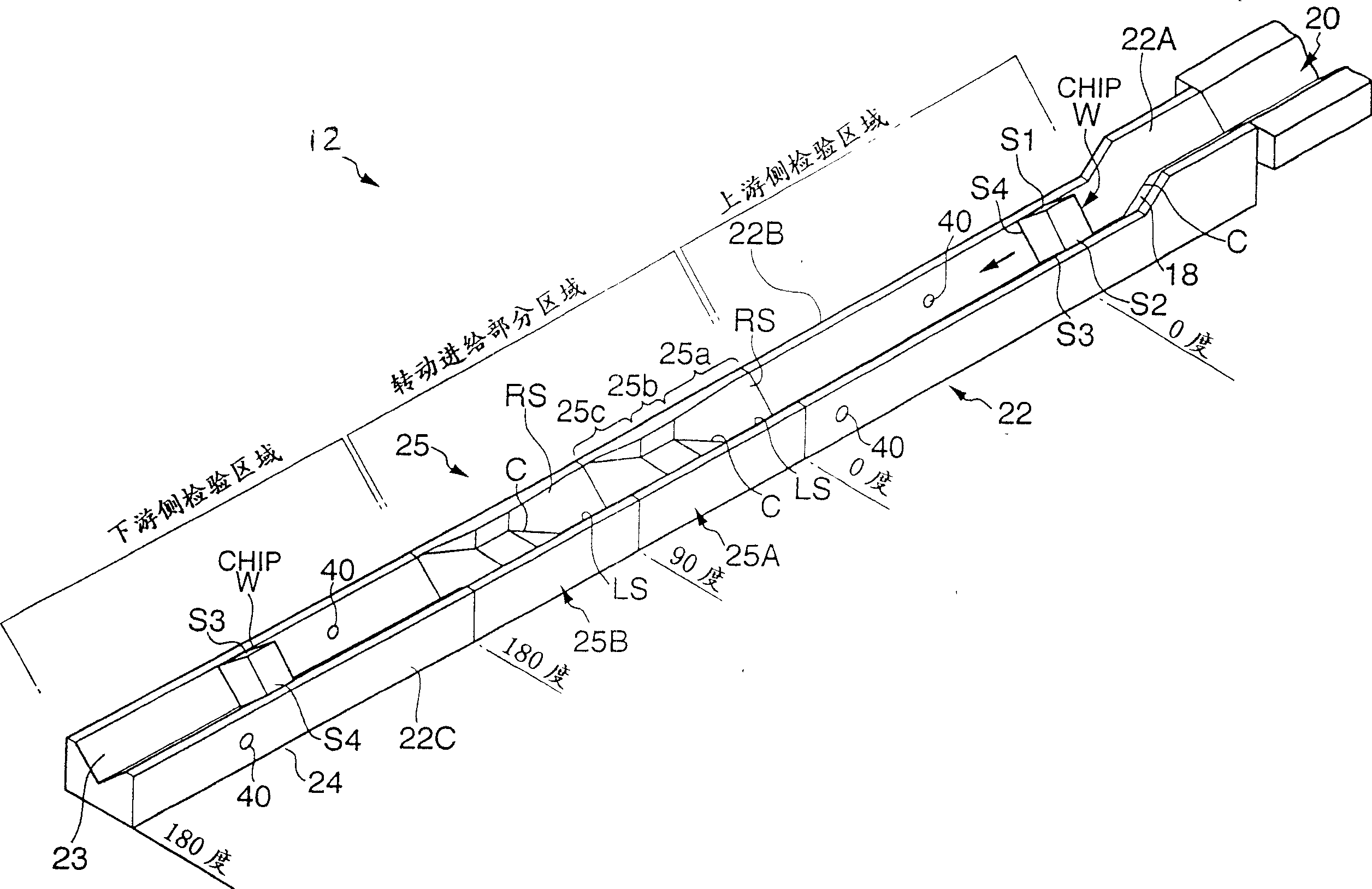

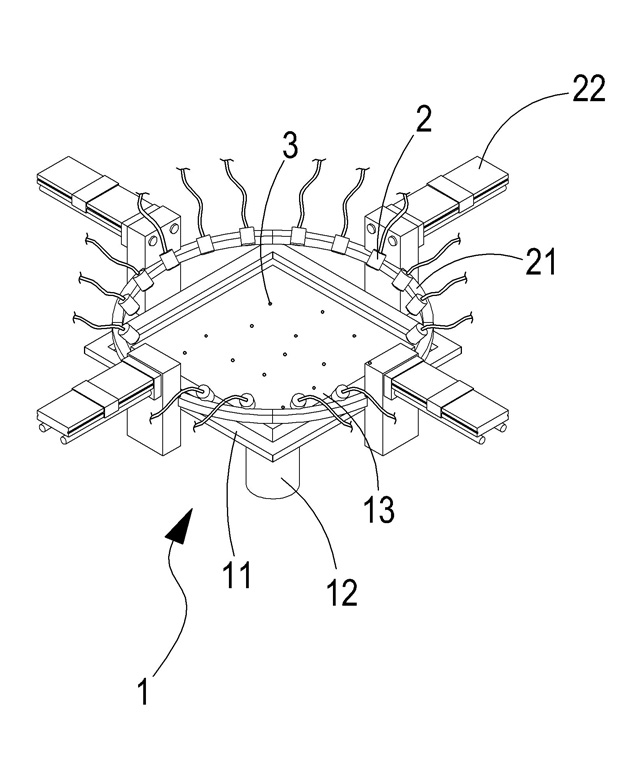

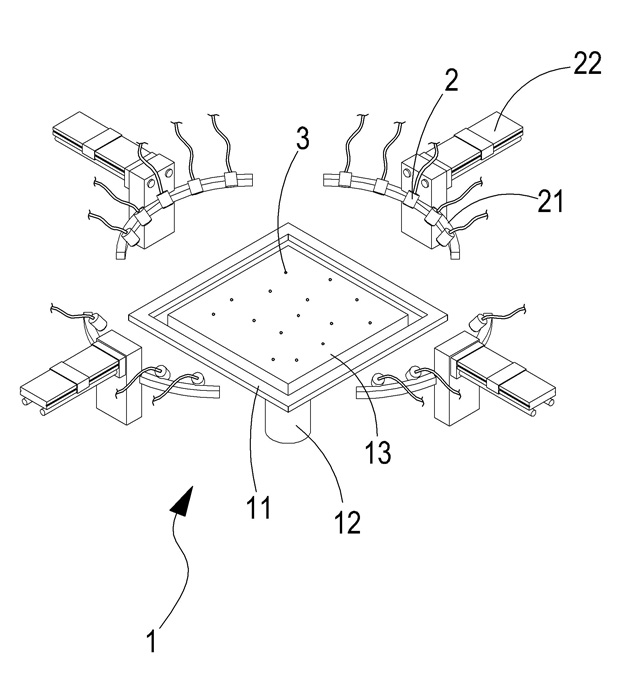

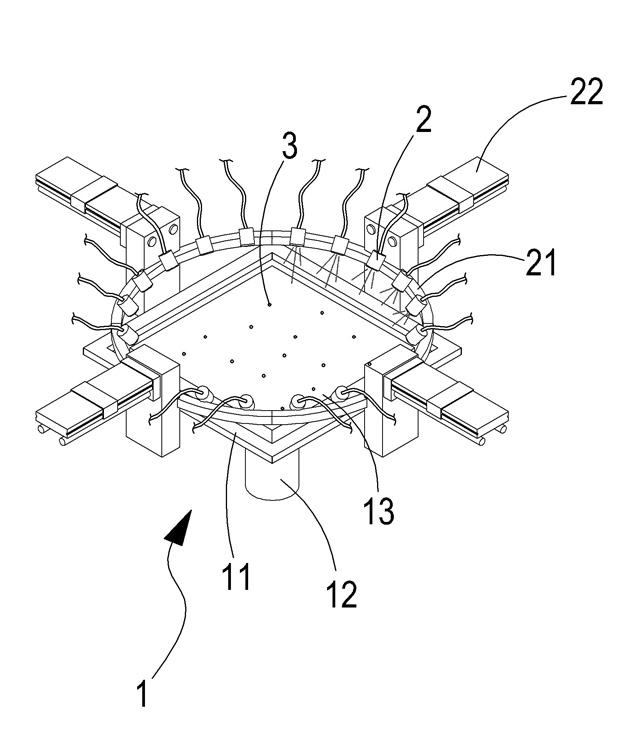

Feeder for polyhedron inspection and polyhedron inspector

InactiveCN1273363CAutomatic inspectionValid inspectionSemiconductor/solid-state device manufacturingOptically investigating flaws/contaminationEngineeringMechanical engineering

A polyhedron inspector (10), comprising a feeder for polyhedron inspection (12) having a passage forming member for inspecting the surfaces of chips (W) in cubic shape, the feeder for inspection polyhedron (12) further comprising generally V-shaped grooves formed therein and two rotatingly feeding parts (25A, 25B) disposed in the passage forming member (22), wherein the rotatingly feeding parts (25A, 25B) are formed in the cross sections of generally V-, U-, and V-shapes arranged in that order, and a chuter (18) for moving the chips (W) one by one apart from each other, cameras (13A to 13D) for inspecting the surfaces of the chips (W) and a recovery means (30) for recovering the chips (W) depending on the inspection results are fitted to the passage forming member (22).

Owner:LINTEC CORP

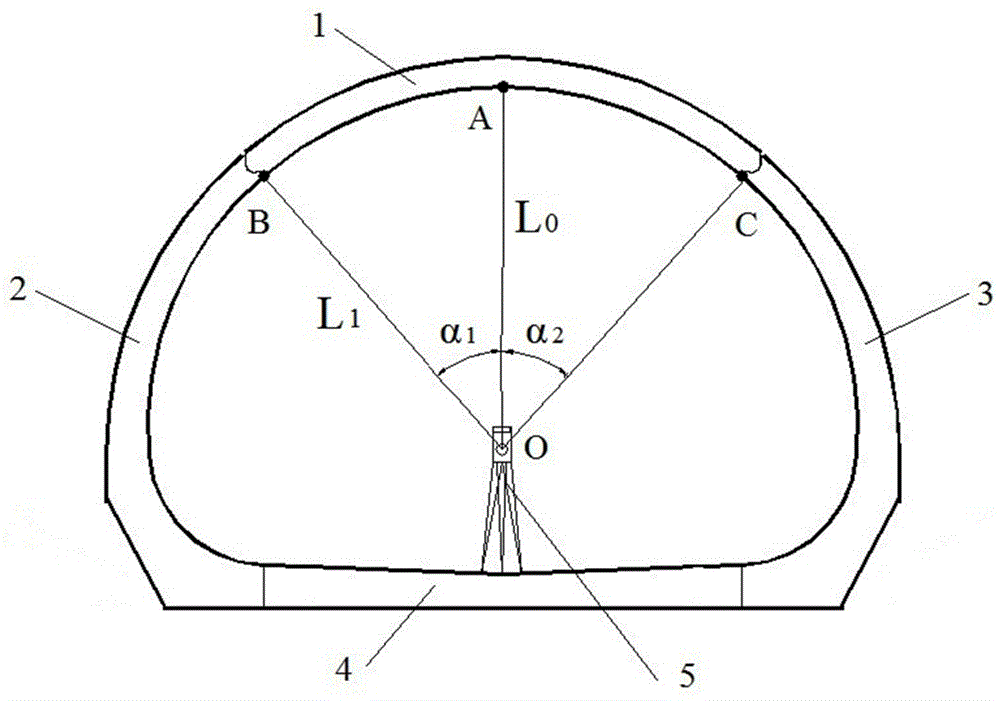

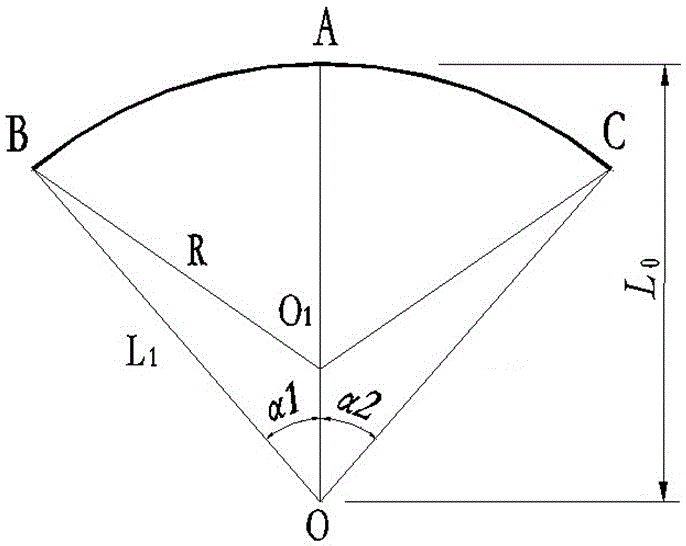

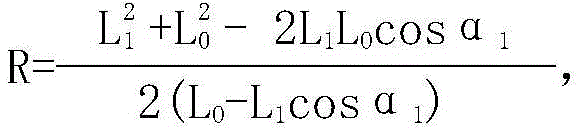

A method for measuring and inspecting the radius of the inner wall of the curved roof of the assembled channel

ActiveCN104121868BValid inspectionThe amount of measurement data is smallUsing optical meansMedial axisEngineering

Owner:ANHUI TRANSPORTATION INVESTMENT GRP

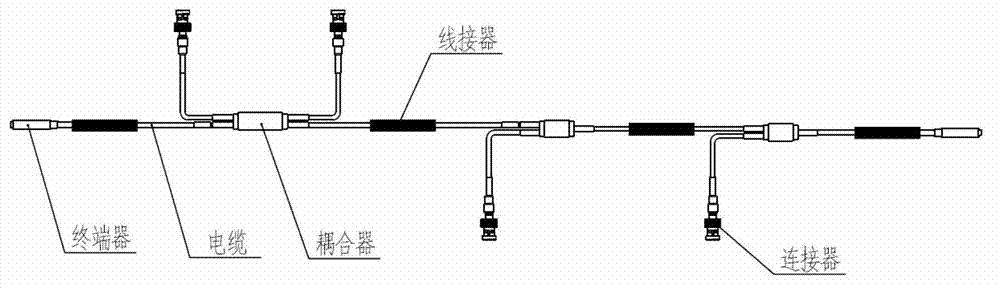

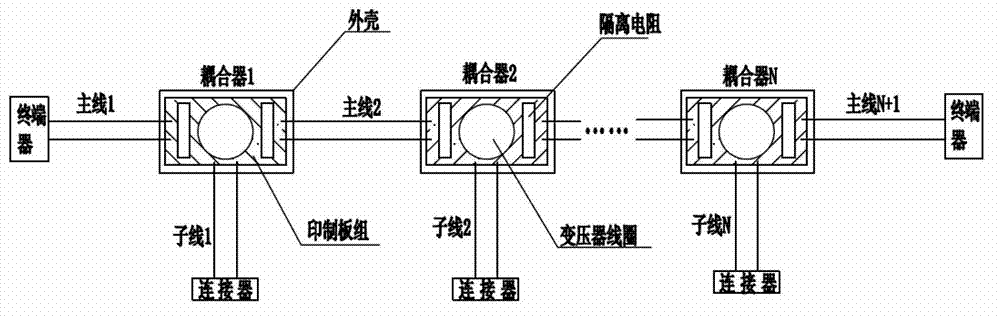

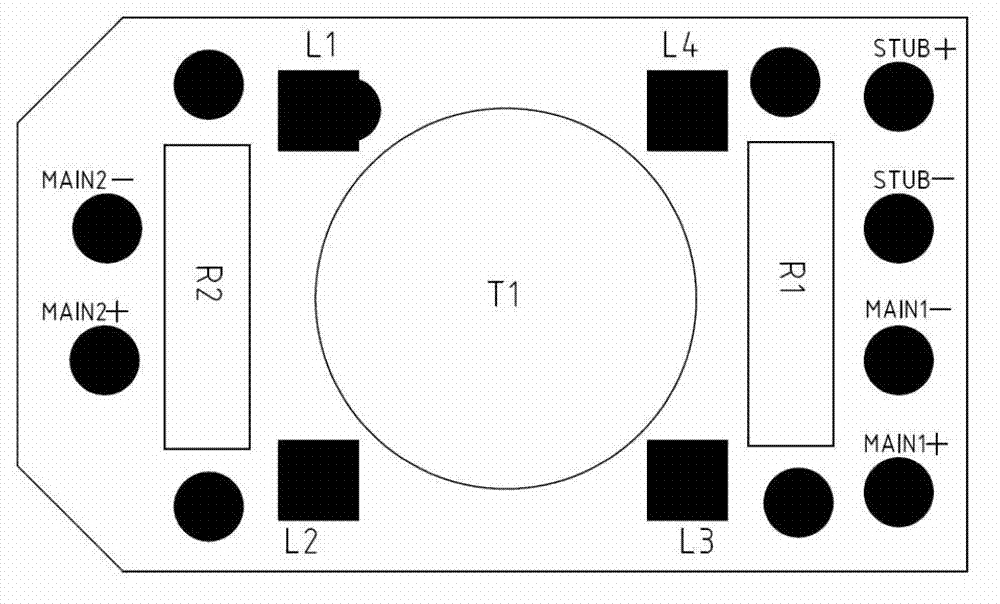

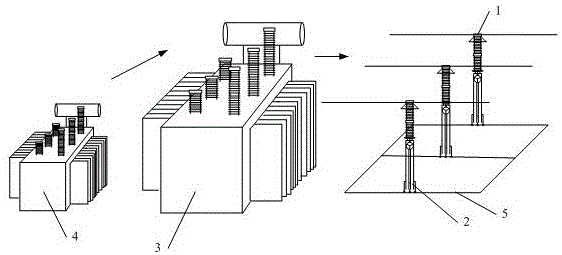

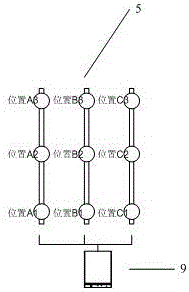

Integration forming method for 1553B bus cable system

ActiveCN103117494AReduce contact resistanceReduce weightLine/current collector detailsCoupling device detailsCouplingFirst principle

The invention discloses an integration forming method for a 1553B bus cable system. The method includes: (1), welding and assembling coupling transform coils and isolation resistances on printed boards to form printed board assemblies; (2), on a first printed board assembly, welding first twisted-pair shielded wires at a positive end and a negative end of a first principle line, welding second twisted-pair shielded wires at a positive end and a negative end of a second principle line, and welding third twisted-pair shielded wires at a positive end and a negative end of a sub-line; and on a second printed board assembly to an Nth printed board assembly, welding second twisted-pair shielded wires at the positive end and the negative end of the second principle line, and wielding third twisted-pair shielded wires at the positive end and the negative end of the sub-line; (3), connecting N printed board assemblies from one end to the other end through the second twisted-pair shielded wires; (4), sleeving coupler casings on the N printed board assemblies and performing processes of filling and sealing; and (5), welding the third twisted-pair wires connected on all the printed board assemblies to connectors, and welding the first twisted-pair wires connected on the first printed board assembly and the second twisted-pair wires connected on the Nth printed board assembly to terminals.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

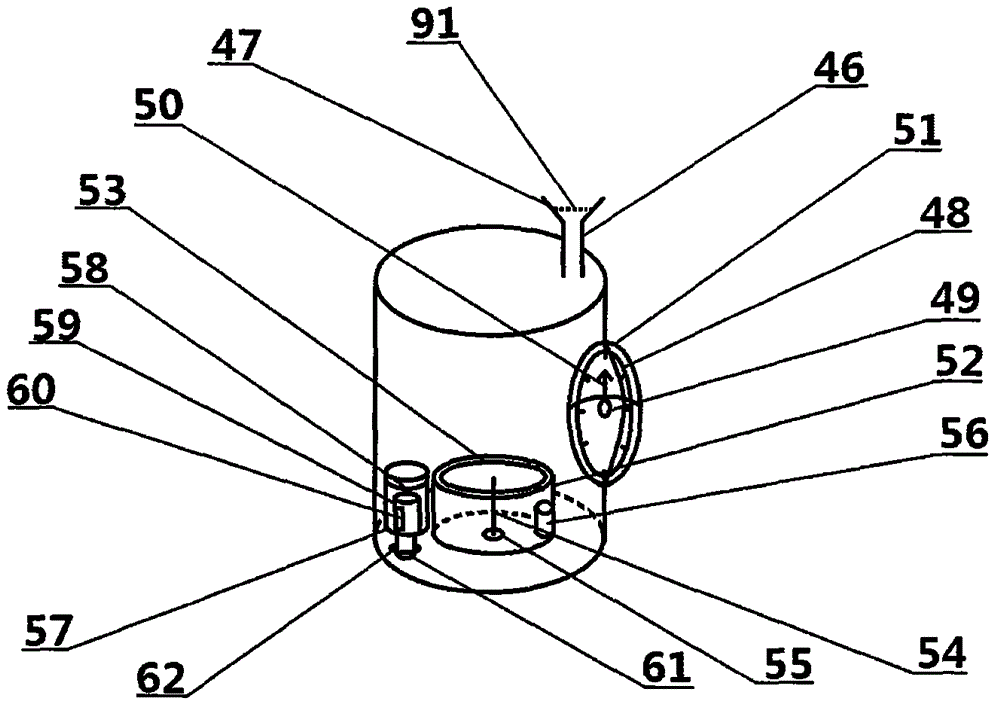

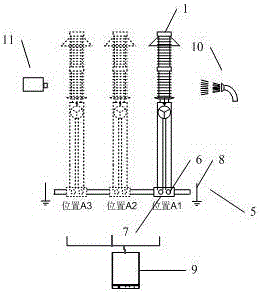

Metal oxide arrester electrification test experiment research system

The invention discloses a metal oxide arrester electrification test experiment research system, which includes: a 110kV main transformer of transformer substation, a bus line, a three-phase metal oxide arrester, a pressure regulator, an arrester leakage electric current testing instrument with electrification, an equivalent salt density solution spraying device and a thermal infrared imager. The metal oxide arrester electrification test experiment research system sets the pressure regulator to change the system operation voltage, the equivalent salt density solution spraying device and the monitoring device running temperature of the thermal infrared imager, which is easy to study the corresponding relation between the change rate of the equipment running temperature and the change rate of the MOA resistive elective current. By further setting the arrester pillar roller track, the system can change the MOA three-phase space position to simulate the operating condition change of the MOA surrounding device. The system is practical for training and teaching or experimental verification. The system can also effectively check the good or worse performance of different MOA leakage electric current test equipment with electrification.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

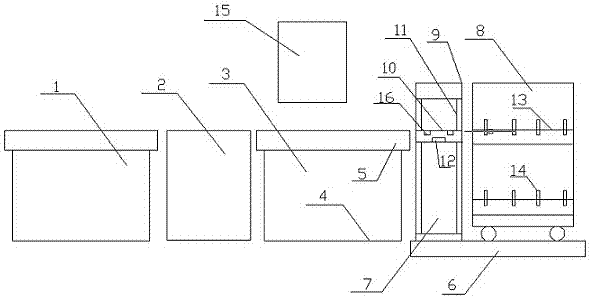

Finished product transporting line for medical electric drill saw

The invention provides a finished product transporting line for a medical electric drill saw. The finished product transporting line comprises a production line, an assembling table and an outward-transporting line. The rear end of the production line is connected with the assembling table. The other end of the assembling table is connected with the outward-transporting line. The outward-transporting line is supported by a base. A conveyor belt is arranged on the outward-transporting line. The conveyor belt is driven by a motor. The tail end of the outward-transporting line is connected with a transshipping table. The transshipping table is provided with an automatic lifting device. The position behind the automatic lifting device is connected with a transshipping frame. By arranging the outward-transporting line, the automatic lifting device and the transshipping frame, the medical electric drill saw is rapidly transported and moved, after being processed by the assembling table, the medical electric drill saw is transported out by the outward-transporting line, the medical electric drill saw is rapidly moved to the transshipping table through the automatic lifting device, the transportation time is greatly shortened, and the labor cost is lowered; by arranging a spot check table, checking can be effectively carried out on finished products by workers, and defective products are prevented from flowing into the market; the finished product transporting line for the medical electric drill saw has the advantages that the structure is simple, the production efficiency is high, and the production cost is lowered.

Owner:WUHU RUIJIN MEDICAL EQUIP

Annular light source test platform

InactiveCN102012377AQuality improvementAddressing the risk of fallingOptically investigating flaws/contaminationElectromechanicsFall risk

The invention discloses an annular light source test platform, which belongs to electromechanics. The annular light source test platform comprises a bearing frame and a plurality of lighting pieces, wherein the bearing frame comprises a bearing platform and a bracket, wherein the bearing platform can be used for fixedly placing a preinstalled photomask; the bracket supports the bearing platform; the lighting pieces are a certain distance from the bearing frame and are arranged on the bearing frame in a surrounding way; and each of the lighting pieces is arranged towards the bearing frame. By using the structure, not only a falling risk which is possible to be caused by artificially gripping the photomask is improved, but also multi-angle test can be provided, so that the lighting quality can be improved and a visual dead angle is avoided.

Owner:GUDENG PRECISION IND CO LTD

Anti-streaky warp screening method of real silk fabric and application

ActiveCN112853574ASolve the Jingliu problemWiden the gap in color absorptionDyeing processDe-gumming silkPolymer scienceAcid dye

The invention discloses an anti-streaky warp screening method of a real silk fabric and application, and belongs to the technical field of real silk dyeing. The screening method comprises the following steps of 1) silk sampling, 2) silk dyeing, 3) silk colorimetry, 4) fabric sampling, 5) fabric dyeing and 6) fabric colorimetry. The step 2 of silk dyeing is performed under an acidic condition by adopting a neutral dye; and the step 5) of fabric dyeing is performed under an acidic condition by adopting a neutral dye or an acid dye. The screening method can effectively solve the problem of streaky warps during dyeing of the real silk fabric, and is applied to screening of the real silk fabric suitable for sensitive color dyeing. The screening method as a screening process is applied to the field of sensitive color dyeing of the real silk fabric.

Owner:ZIBO DARANFANG SILK GRP

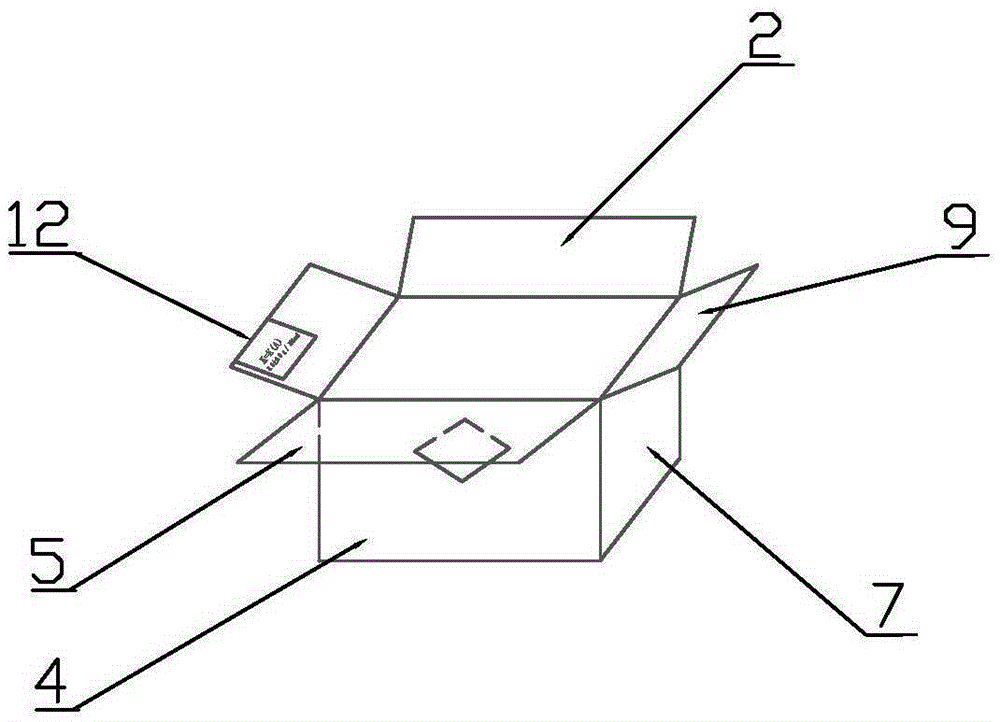

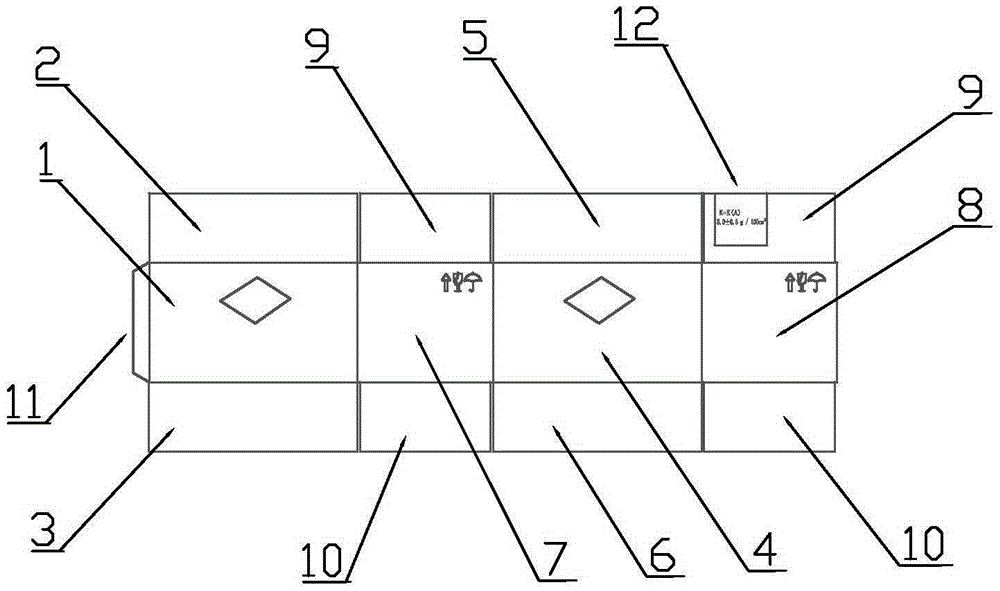

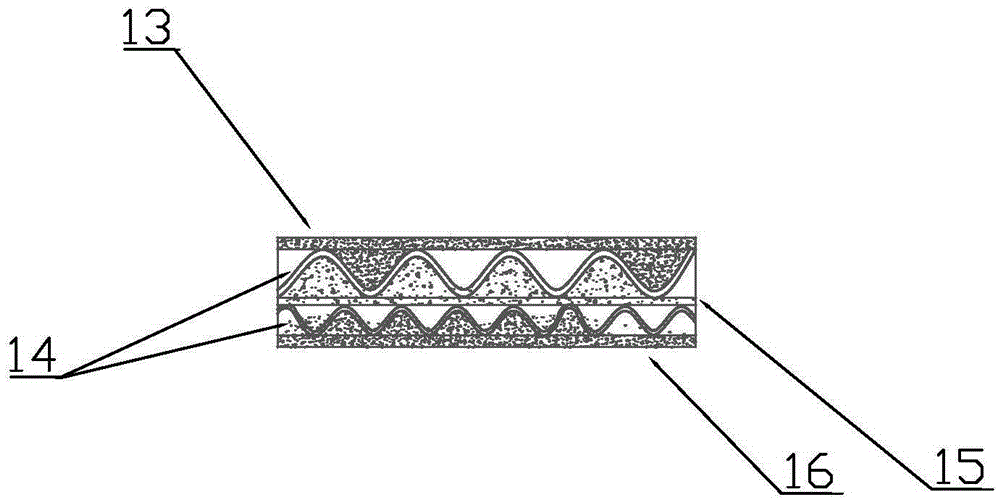

Carton quality inspection and detection method

The invention discloses a carton quality inspection and detection method comprising the steps of carton printing, patch prefabricating, carton sampling, shape detection, slice cutting, gap filling, slice shape and position test, slice performance test and data processing. Slice marking lines are printed on all cartons, cartons are selected through sampling, and slice sampling is carried out at the marking lines. The quality, thickness, compressive strength and impact strength of slices are tested, and the quality and performance of all the cartons are judged through data processing. The quality of cartons is measured and detected in a simple and practical method. By adopting the method, the quality of cartons can still be effectively inspected and controlled under the condition that there is neither bursting strength test equipment nor drop test equipment in the factory.

Owner:KUNSHAN GUOJI ELECTRONICS

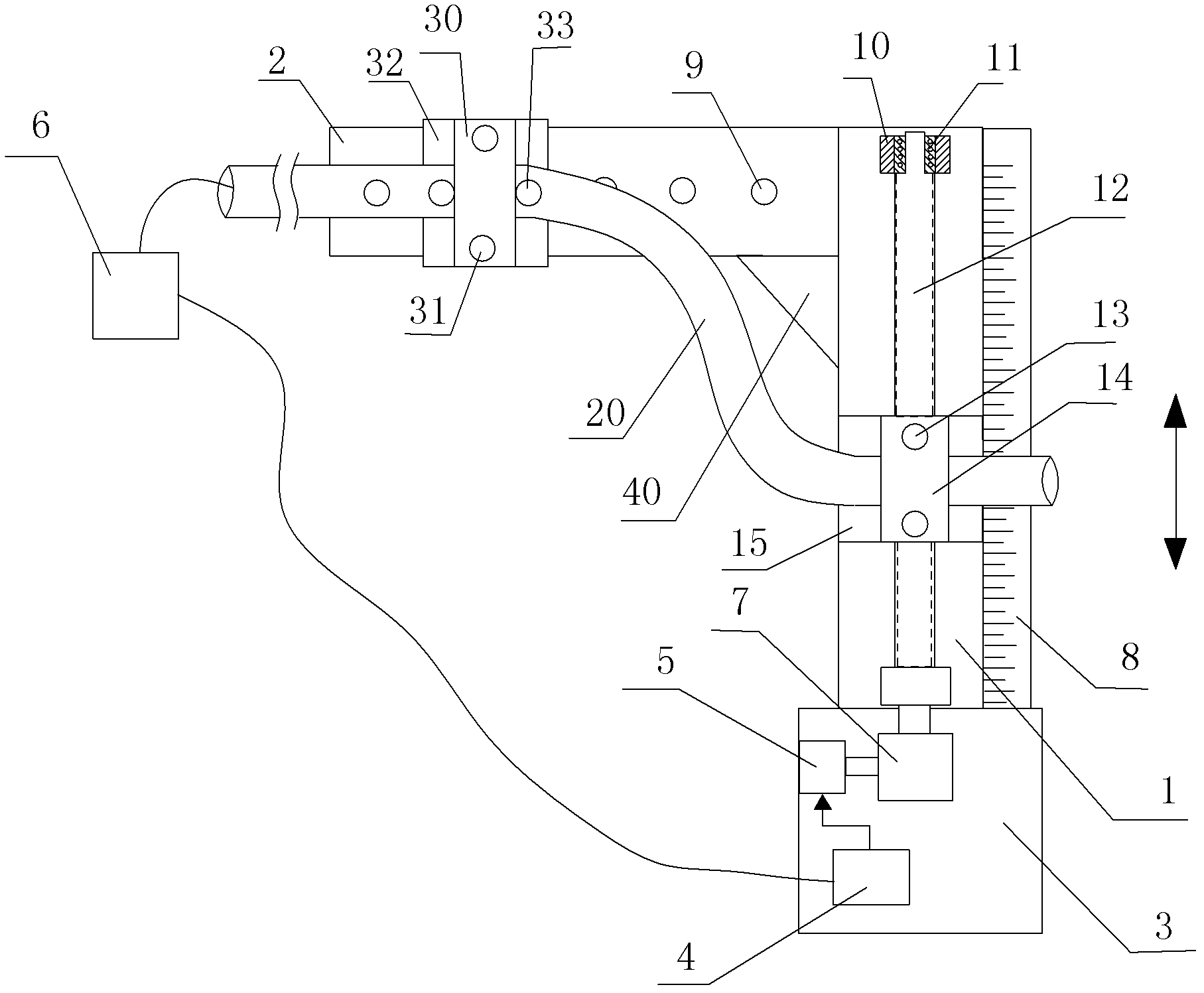

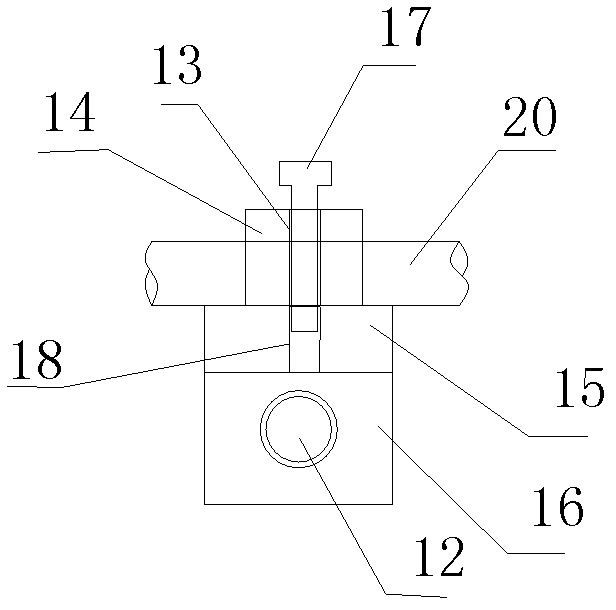

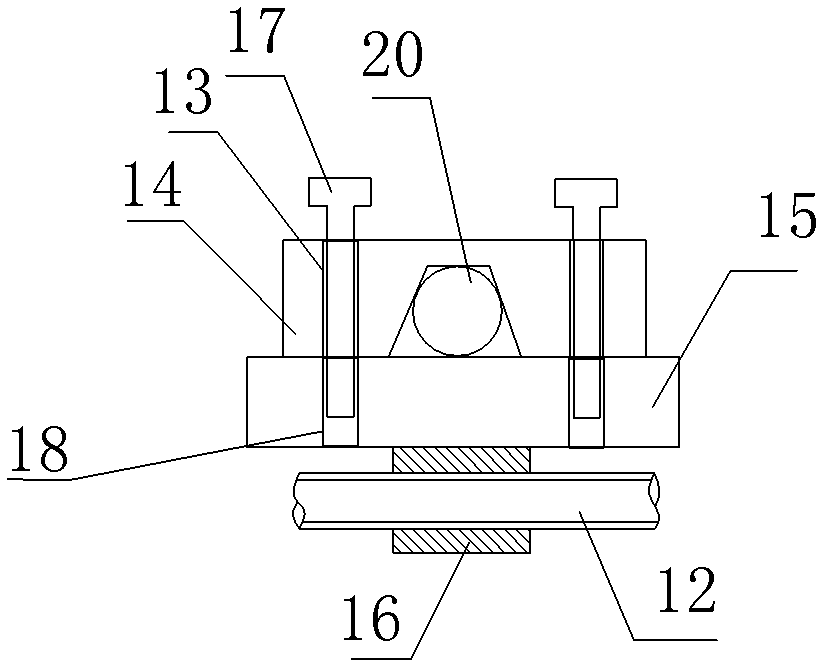

Calibration and testing device of landslide monitoring device

The invention discloses a calibration and testing device of a landslide monitoring device. The calibration and testing device of the landslide monitoring device comprises a first substrate and a second substrate. An end head of the first substrate is provided with a third substrate. A rotatable screw rod is placed on the first substrate. One end of the screw rod is connected with a speed changing box fixed on the third substrate. A control module is connected with a motor. A second moving plate matched with the screw rod in a threaded mode is provided with a first moving plate. A first screw hole matched with a first bolt in the threaded mode is formed in the first moving plate. The first bolt penetrates the first through hole in a first pressing plate provided with a groove and fixes the first pressing plate on the first moving plate. The landslide monitoring device is clamped between the first moving plate and the first pressing plate. A fixing hole is formed in the second substrate. A third through hole is formed in a fixing plate. The landslide monitoring device is clamped between the fixing plate and a second pressing plate. The landslide monitoring device is connected with a testing module. The calibration and testing device of the landslide monitoring device is simple in structure, reasonable in design, convenient to use and capable of effectively calibrating or testing the landslide monitoring device.

Owner:XIAN JINHE OPTICAL TECH

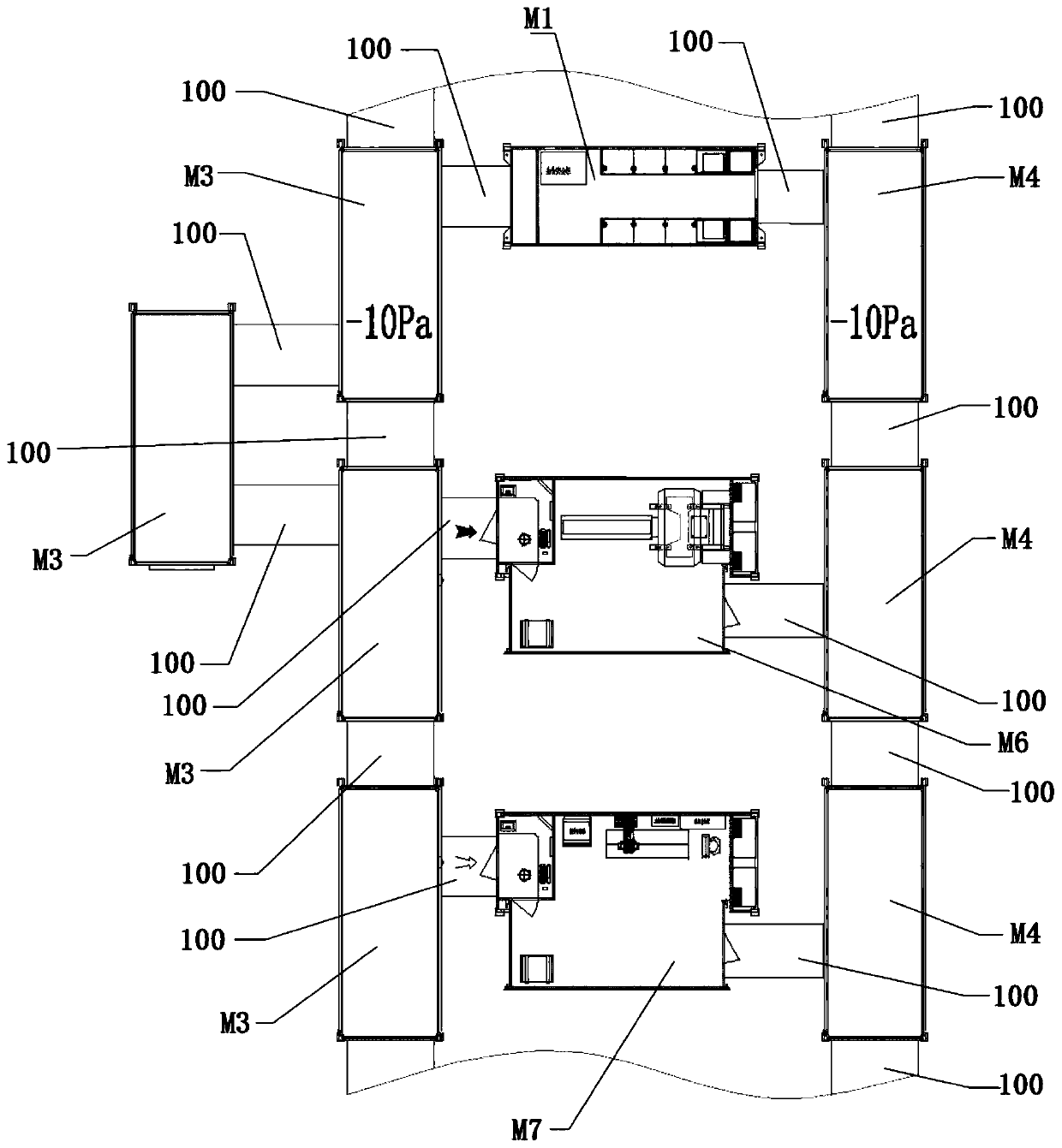

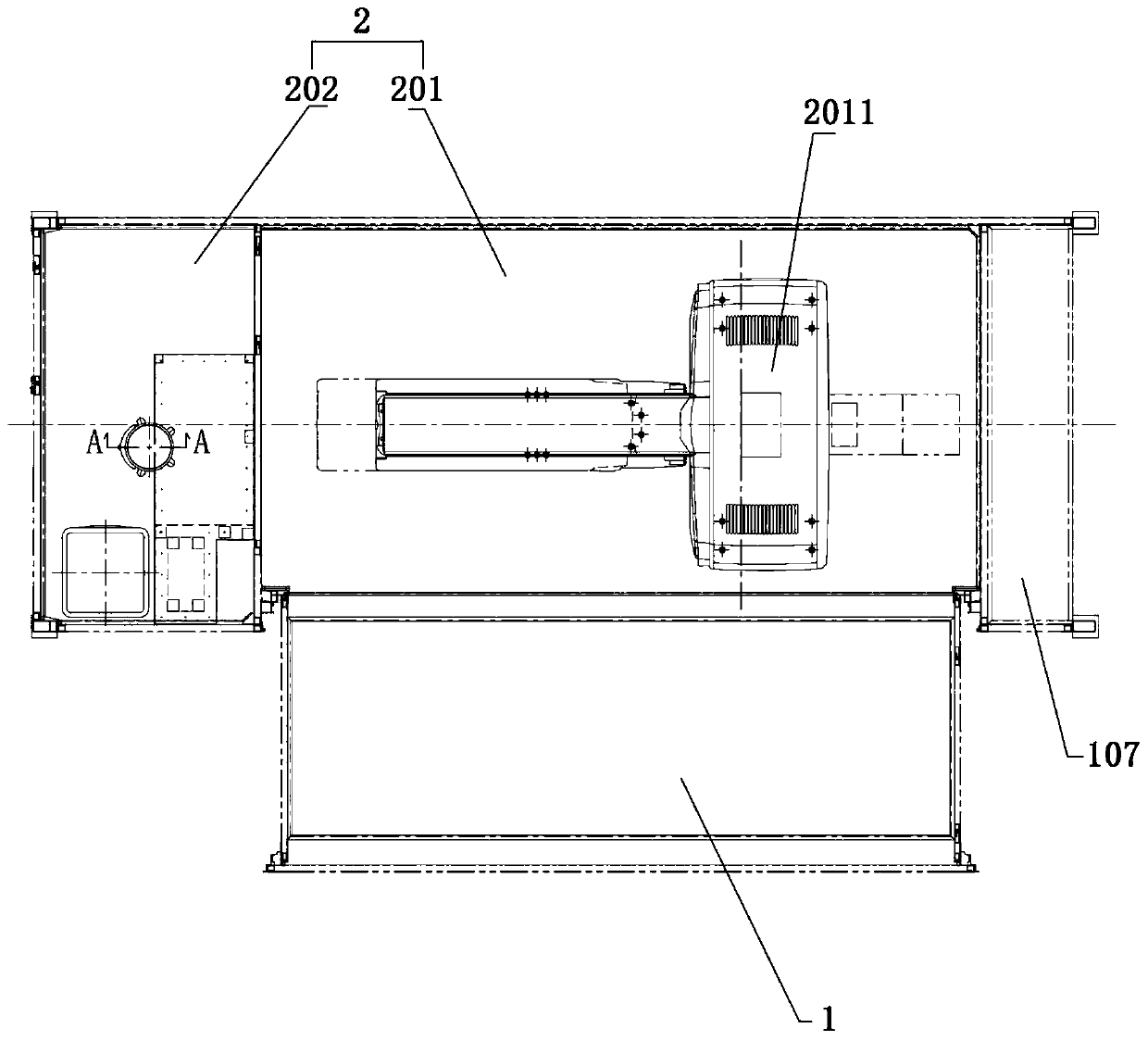

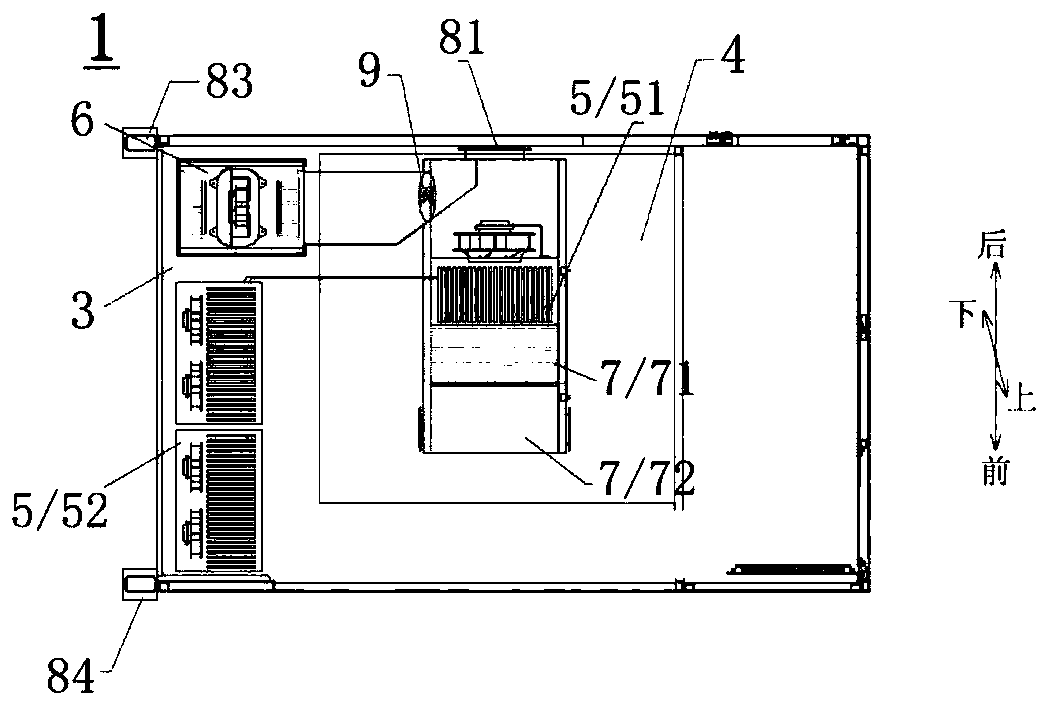

Diagnostic Imaging module of negative-pressure shelter

PendingCN111536584AAchieve transshipmentImprove mobilityDucting arrangementsMechanical apparatusPatient roomMedical imaging

The invention relates to a diagnostic Imaging module of a negative-pressure shelter. The diagnostic Imaging module comprises a ward unit, a CT unit and a DR unit; the improvement is that the same sideof the ward unit, the CT unit and the DR unit are connected through a channel device; the side parts of the ward unit, the CT unit and the DR unit are all connected with a negative-pressure shelter body by which a negative pressure difference not lower than 20 Pa can be formed between the external environment and the ward unit, the CT unit and the DR unit; and the negative-pressure shelter body can also form a negative pressure difference not lower than 10 Pa between the external environment and a medical care channel unit, a patient channel unit and the channel device. The diagnostic Imagingmodule provided by the invention can realize lung-based medical imaging screening and diagnosis of infectious patients, has a negative pressure function, comprises a retractable channel device, and amobile device, and can provide an effective examination, treat and cure place for natural disasters, local wars, infectious disease prevention and the like.

Owner:SUZHOU JIANGNAN AEROSPACE MECHANICAL& ELECTRICAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com