Feeder for polyhedron inspection and polyhedron inspector

A technology for testing equipment and polyhedrons, which is applied in semiconductor/solid-state device manufacturing, instruments, transportation and packaging, etc. It can solve problems such as large equipment size, conveyors that cannot be arranged in a straight line, and complex structures, and achieve reliable inspection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

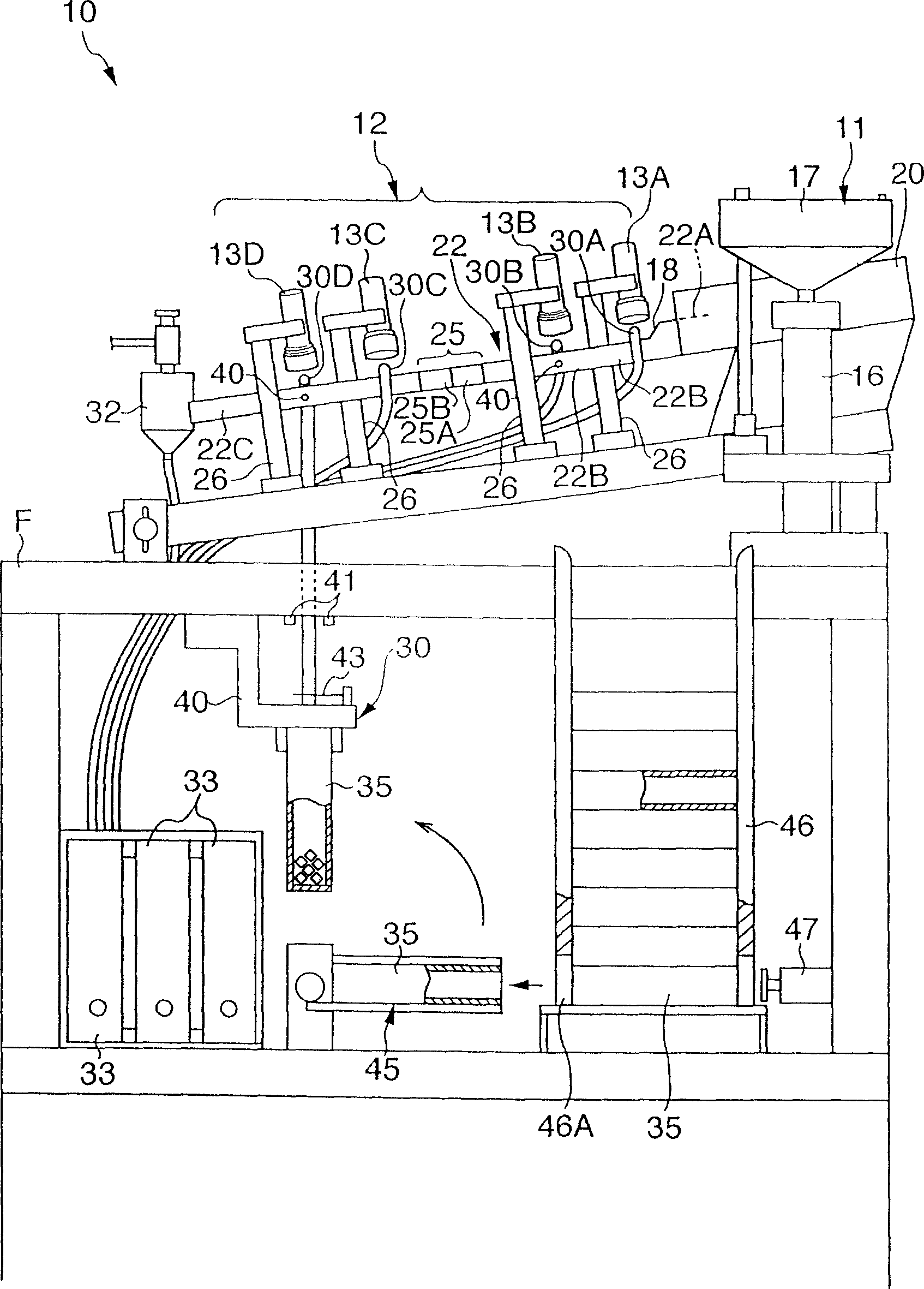

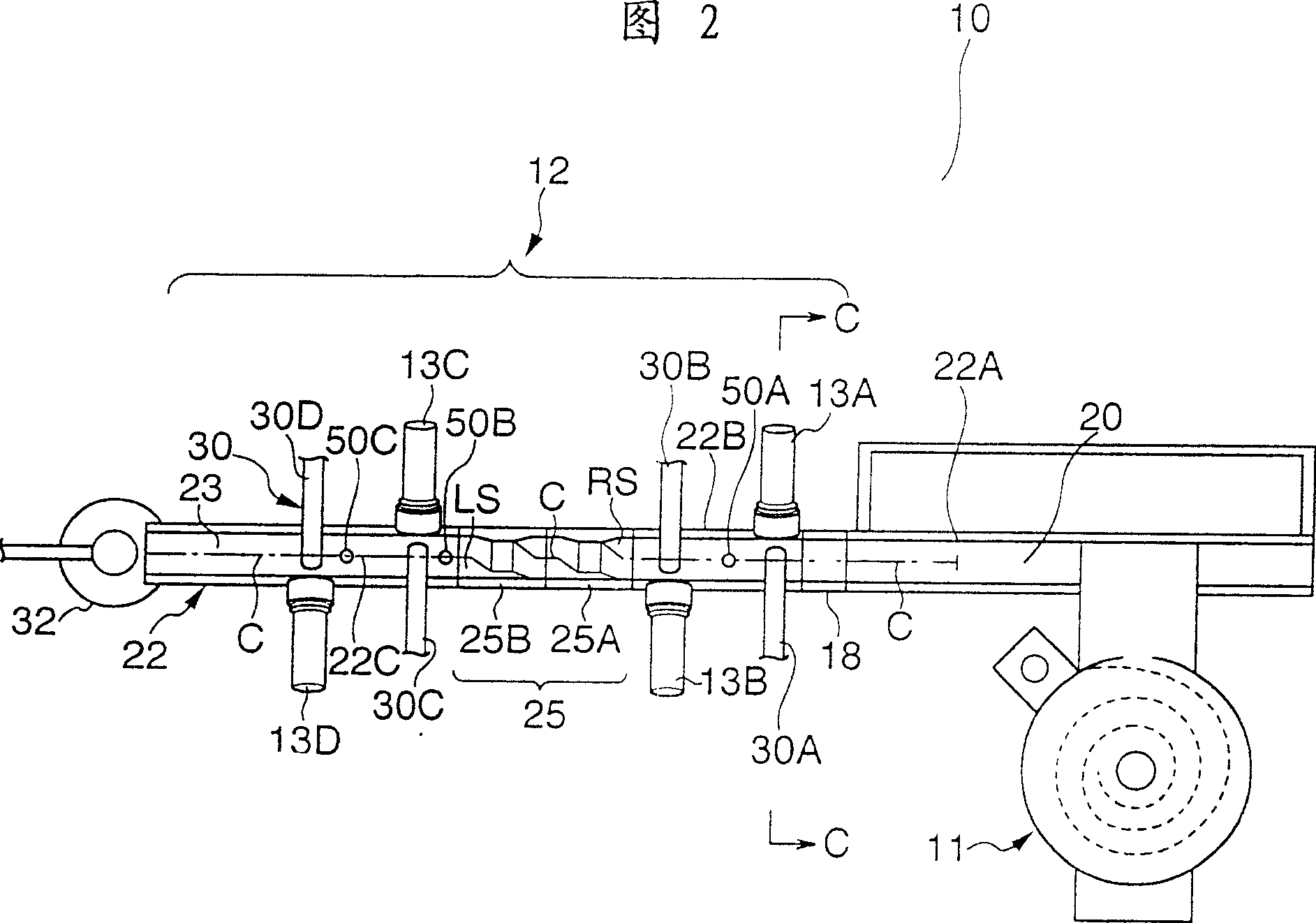

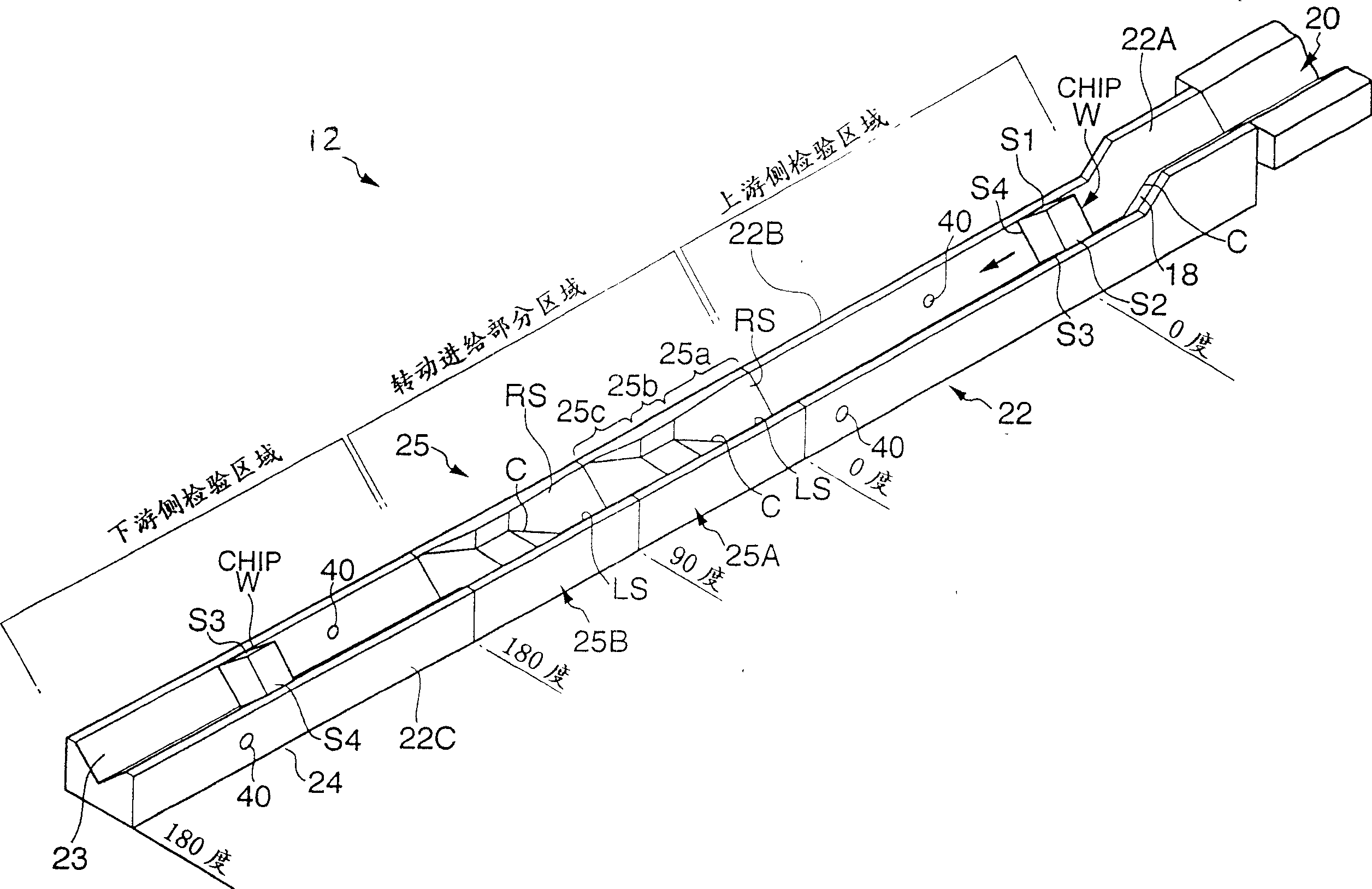

[0031] An embodiment of the present invention will be described below with reference to the accompanying drawings.

[0032] figure 1 The front view of Fig. 2 schematically represents the overall structure of the polyhedron inspection equipment of the present invention, and the top plan view of Fig. 2 represents figure 1 Major parts of the polyhedron inspection equipment shown. like figure 1 As shown in FIG. 2, the polyhedron inspection apparatus 10 includes a supply unit 11, a polyhedron inspection feeder 12 (see FIG. 2), first to fourth cameras 13A to 13D serving as inspection means, and a recovery unit 30. More specifically, a supply device 11 is provided on an upper portion of one frame F, and a polyhedron inspection feeder 12 moves inspection items supplied from the supply device 11, which in this embodiment are cubic ceramic block capacitors (hereinafter referred to as Pellet W). First to fourth cameras 13A to 13D are arranged above the polyhedron inspection feeder 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com