Test device and method for generator rotor winding turn-to-turn short-circuit fault monitoring device

A technology for inter-turn short-circuit faults and generator rotors, applied to measuring devices, measuring electrical variables, instruments, etc., can solve problems such as no way to calibrate, lack of effective calibration means for monitoring devices, and inability to detect problems in advance, so as to improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

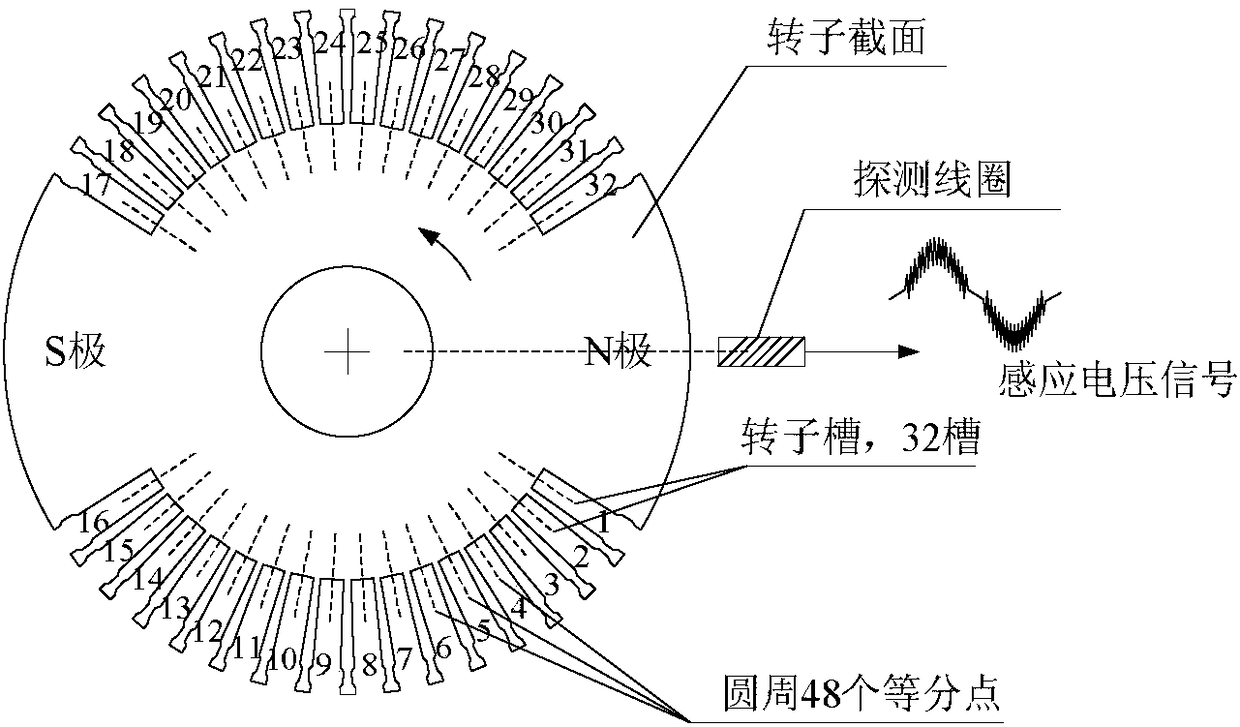

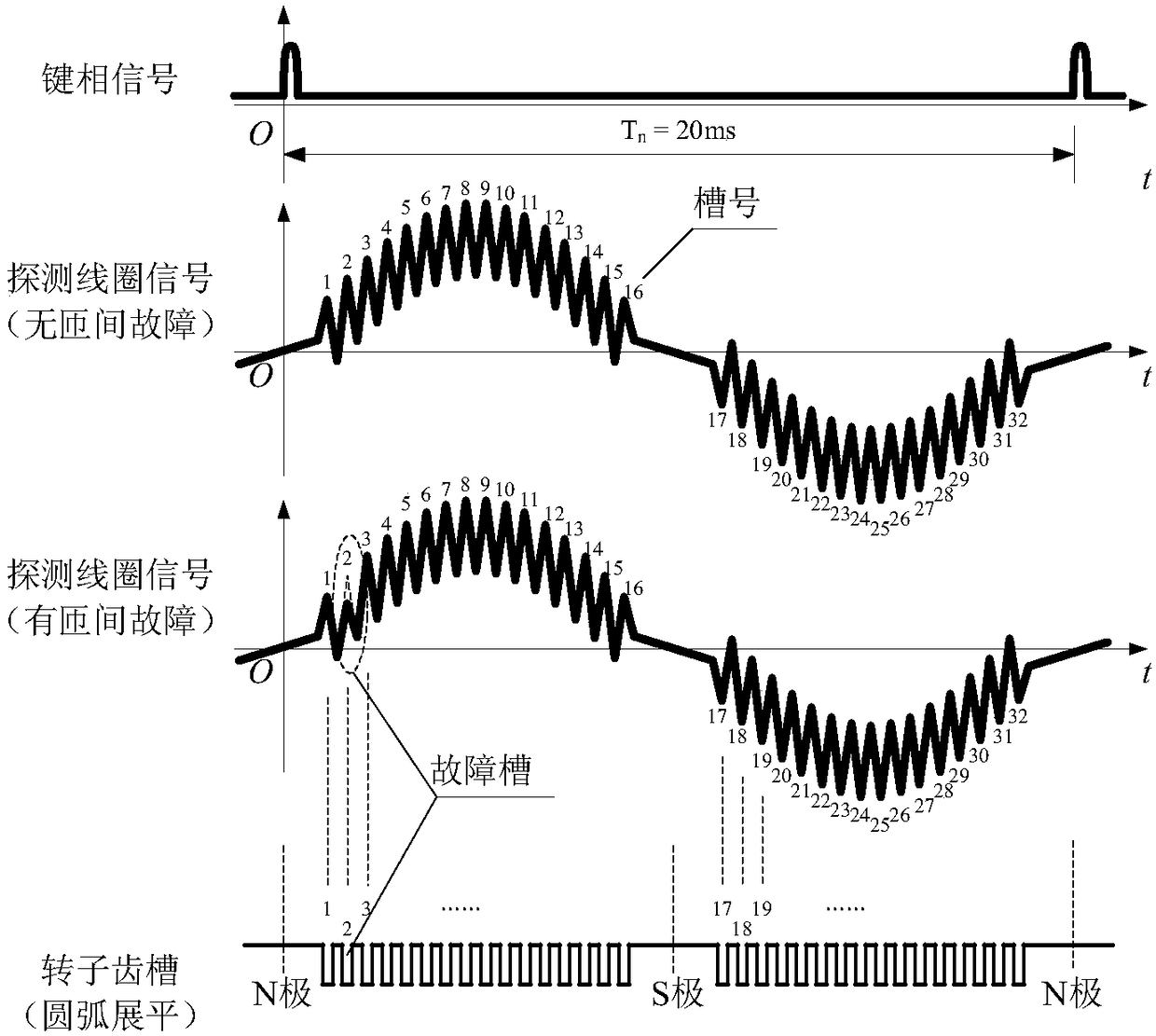

[0030] figure 1 It is a schematic diagram of a 600MW generator rotor section and detection coil. figure 1 The key phase signal and the rotor turn-to-turn fault monitoring device are omitted. figure 1 The rotor of the generator in is a pair of poles, that is, an N pole and an S pole; there are 48 equal points on the circumference of the rotor, and 32 of them are symmetrically slotted to obtain 32 slots in the rotor, and the slot pitch angle is 7.5deg; power frequency f n =50Hz, the rated speed of the generator is 3000rpm, and the rotation time is 20ms; the detection coil is installed on the inner wall of the generator stator; the key phase signal and the detection coil voltage signal are input to the rotor inter-turn fault monitoring device at the same time, and the monitoring device samples and records the key phase in real time signal, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com