Integration forming method for 1553B bus cable system

A molding method and bus cable technology, applied in the direction of line/collector parts, circuits, electrical components, etc., can solve the problem of impedance discontinuity, achieve the effect of excellent mechanical performance, small contact resistance, and aggravate signal attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

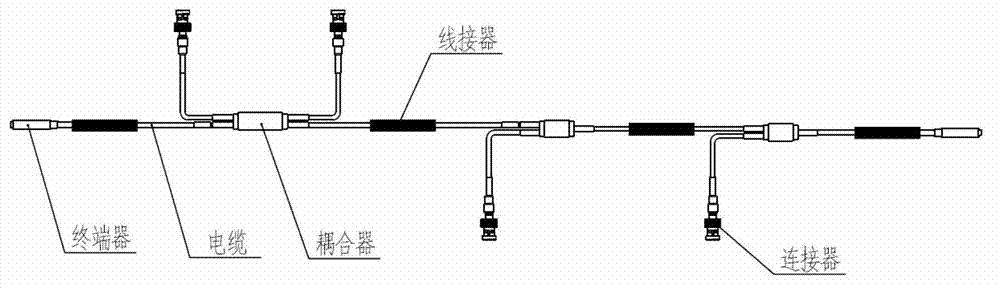

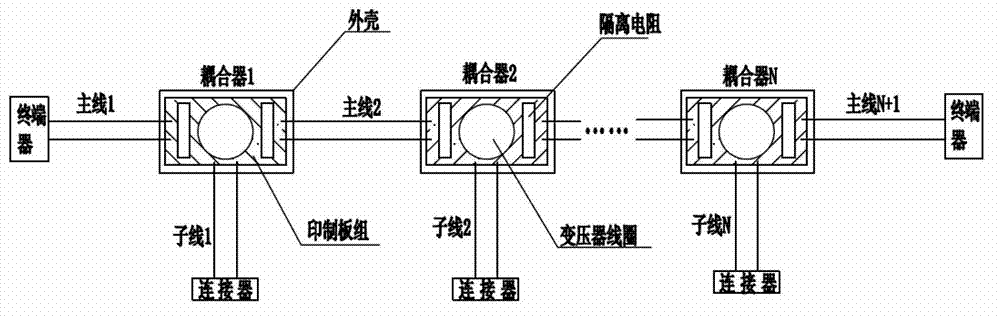

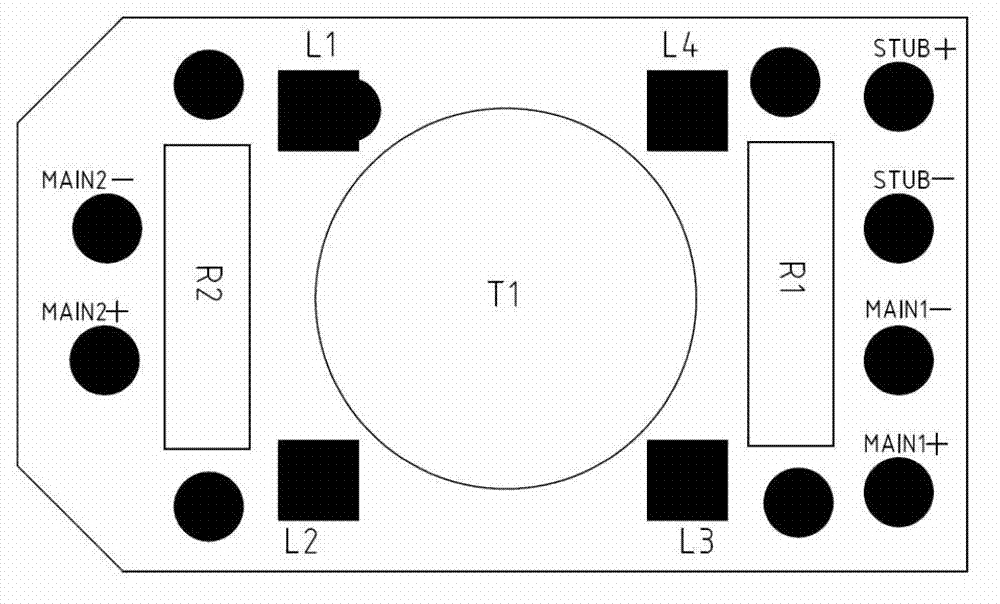

[0025] One of the most important reasons why the 1553B bus is widely used is its high reliability, and its bit error rate is extremely low. The bit error rate is an intuitive indicator to measure the performance of the 1553B bus. There are many factors that affect the bit error rate of the 1553B bus. The impact of the cable network on the reliability of the bus is manifested as increasing or reducing the waveform distortion on the bus. Increasing the waveform distortion will lead to an increase in the bit error rate of the bus. Therefore, the waveform distortion is the performance of the bus cable network. direct measurement of . Waveform distortion is mainly caused by the impedance discontinuity of the cable network and the reflected wave generated on the coupler. In order to reduce the waveform distortion on the bus, in addition to ensuring the performance of individual components when assembling the cable network, the continuity of the entire cable network should be maintai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com