Device for comparing test performance of force measuring locking anchor pipes of tunnel and test method

A technology for locking foot anchors and testing performance, which can be used in measurement devices, force measurement by measuring the change of optical properties of materials when they are stressed, force/torque/work measurement instrument calibration/testing, etc., which can solve the problem of national resources. Waste, tunnel construction buried, safety hazards and other issues, to achieve the effect of good theoretical basis and support, simple installation method, effective feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

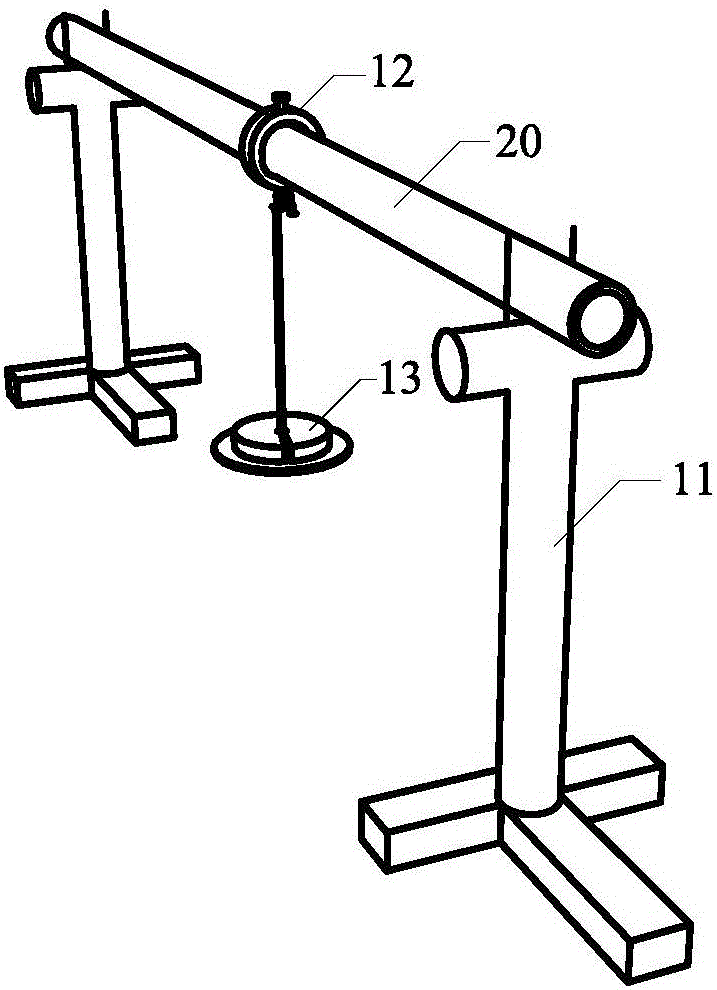

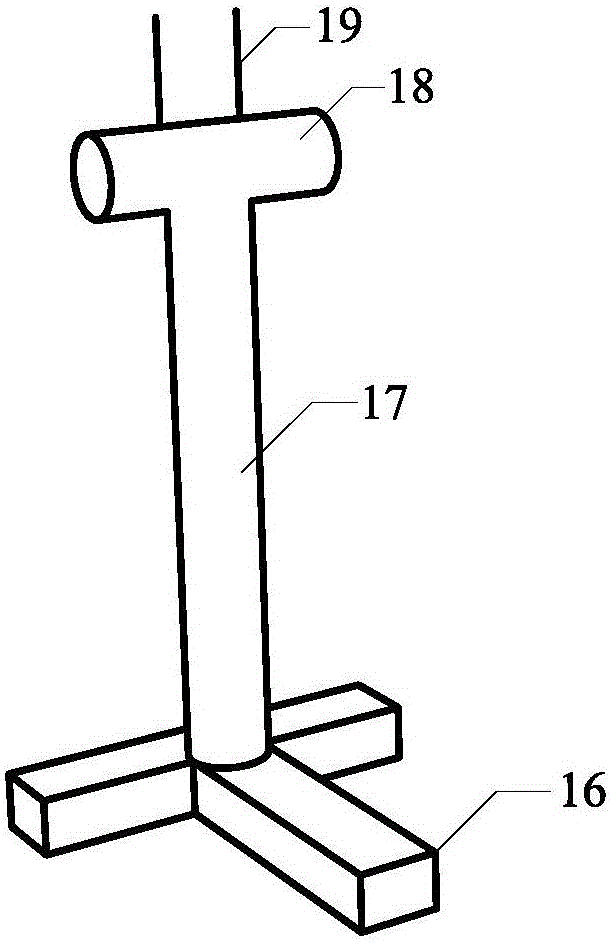

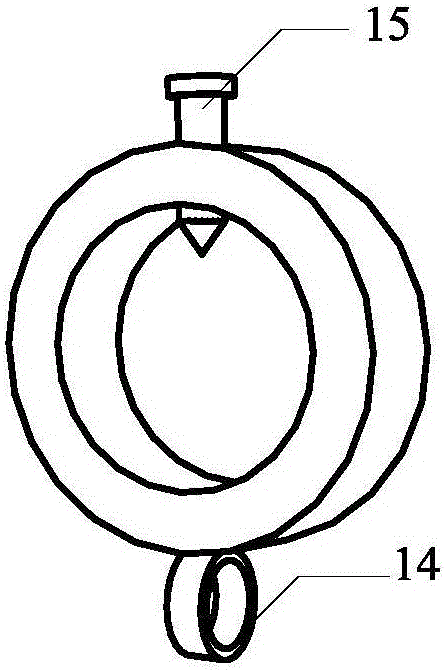

[0068] The test was carried out in the Key Laboratory of Bridges and Tunnels, Chang'an University, Shaanxi Province. The welded steel support frame was used as the hinge support at both ends of the simply supported beam, and the force-measuring lock-foot anchor tube was used as the beam part of the simply supported beam. Weights are stacked just below the loading ring to simulate the concentrated load experienced by a simply supported beam. The main purpose of the test is to compare the test performance of the force-measuring lock-foot anchor tube with embedded bare fiber gratings and the force-measuring lock-foot anchor tube with resistance strain gauges under load. The test performance of the lock-foot anchor tube is compared, and the force characteristics of the force-measuring lock-foot anchor tube with embedded fiber gratings are analyzed. The data acquisition system used in this test electrical measurement method is the TST3821E wireless telemetry static strain gauge, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com