Method for inspecting water circulation system in water-cooling winding of turbonator

A technology of a steam turbine generator and an inspection method, which is applied in the directions of using electric devices, electromagnetic means, and thermometers using electric/magnetic components directly sensitive to heat, etc., can solve the problem of affecting the test results and sensitivity and the duration of inspection Procrastination is very long, and the test curve and results are sensitive, fast and effective inspection, and the inspection results are accurate and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

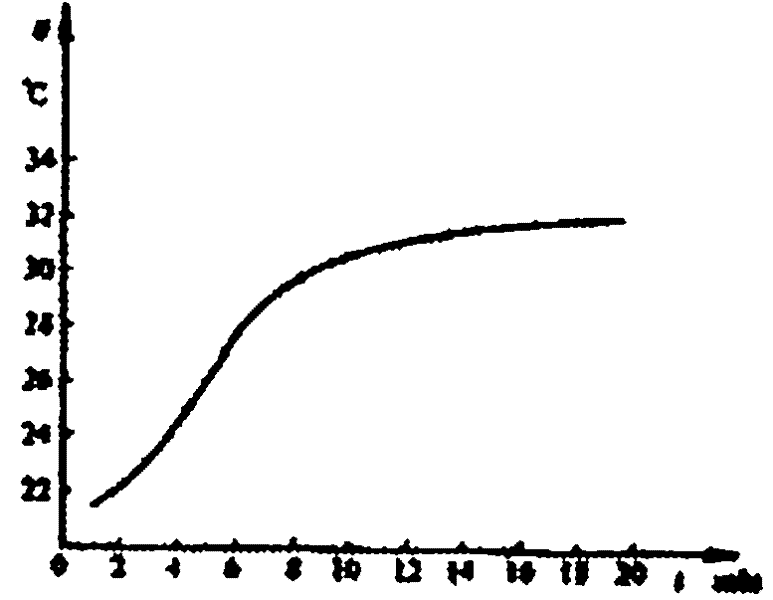

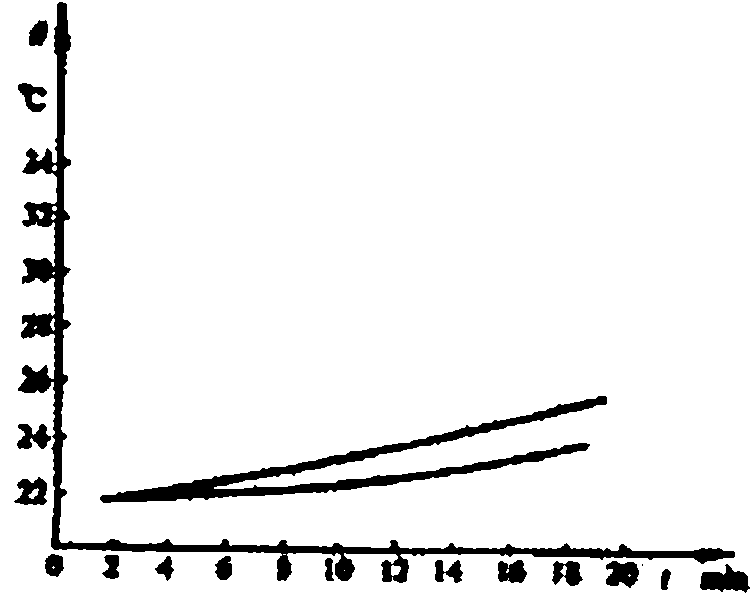

[0008] Specific embodiment one: this embodiment comprises the following steps: one, the thermocouple of the temperature rise measuring device is arranged on the outer surface of the water outlet pipe of each stator winding respectively; water at normal temperature; 3. After reaching a stable temperature, then feed high-temperature water of the same temperature into each stator winding; at the same time, by recording the process of temperature change on the outer surface of the water outlet pipe; 4. Calculate the outer surface of each water outlet pipe The rate of surface temperature change, for the outlet pipe whose temperature change rate is less than 10% of the average temperature change rate, it is considered as a stator winding with internal blockage.

[0009] The inspection method of this embodiment is designed based on the principle that the temperature difference between the cooling water in the stator winding and the heated cooling water is large when the generator is i...

specific Embodiment approach 2

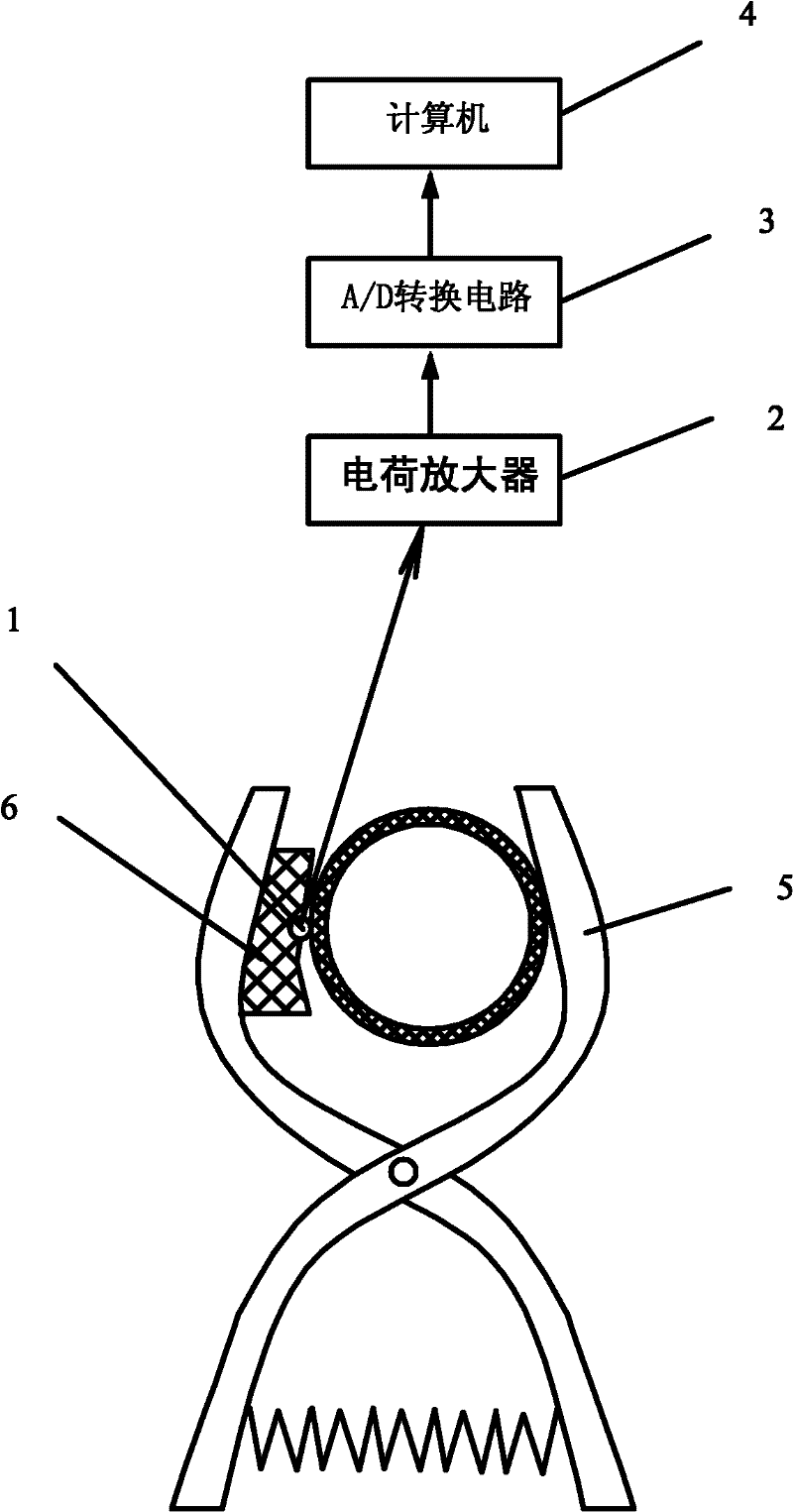

[0010] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the temperature rise measuring device includes a thermocouple 1, a charge amplifier 2, an A / D conversion circuit 3, a computer 4, a spring clip 5 and a thermal insulation material cover 6, and the thermocouple 1 The signal output end of the charge amplifier 2 is connected to the signal input end of the charge amplifier 2, the signal output end of the charge amplifier 2 is connected to the signal input end of the A / D conversion circuit 3, and the signal output end of the A / D conversion circuit 3 is connected to the signal input end of the computer 4; A bread of the thermal insulation material covering body 6 is wrapped around half of the spherical thermocouple 1 , and the other surface of the thermal insulation material covering body 6 is fixed on the inner surface of a pincer arm of the sprin...

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the thermocouple 1 is a manganese-constantan thermocouple, which is formed by sintering the ends of the manganese-copper wire and the constantan wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com