V-shaped cutting deviation detecting method of circuit board

An offset detection and circuit board technology, applied in the field of circuit board manufacturing, can solve the problems of V-CUT line offset, V-CUT short circuit, single PCS out of tolerance, etc. effect of the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The circuit board V-shaped cutting offset detection method is used in the production of double-sided boards, and the board-making process is as follows:

[0014] Sending materials→drilling→full plate copper plating→dry film→graphic plating→etching→solder mask→text→forming→finished product inspection.

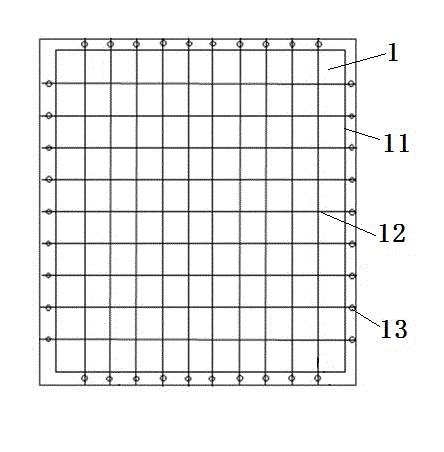

[0015] Other steps are carried out using the existing technology, but in the drilling process, the V-CUT offset inspection hole drilling program is added to the drilling program, and the V-CUT offset inspection hole drilling program setting: the first drilling before or after the hole, such as figure 1 As shown, outside the molding line 11 of the circuit board substrate 1, a V-CUT offset inspection hole 13 is drilled at both ends of each V-CUT line 12 to be V-shaped cutting, and the V-CUT offset inspection hole The diameter of the V-CUT is 0.8 mm, and the distance between the V-CUT offset inspection hole and the molding line is 1 mm. In the dry film process, the V-CUT l...

Embodiment 2

[0017] The circuit board V-shaped cutting offset detection method is used in the production of four-panel, and the board-making process is as follows:

[0018] Sending materials→drilling→full plate copper plating→dry film→graphic plating→etching→solder mask→text→forming→finished product inspection.

[0019] Other steps are carried out using the existing technology, but in the drilling process, the V-CUT offset inspection hole drilling program is added to the drilling program, and the V-CUT offset inspection hole drilling program setting: the first drilling Before or after the hole, outside the forming line of the circuit board substrate, drill a V-CUT offset inspection hole at both ends of each V-CUT line to be V-shaped cutting, the diameter of the V-CUT offset inspection hole The distance between the V-CUT offset inspection hole and the molding line is 2 mm. In the dry film process, the V-CUT line is canceled on the film. After the circuit board is formed, check whether the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com