Automatic feeding unit

A feeding and automatic technology, applied in the field of livestock and poultry breeding, can solve the problems of consumption and large labor costs, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

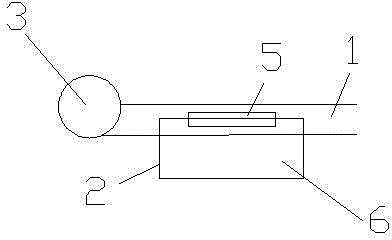

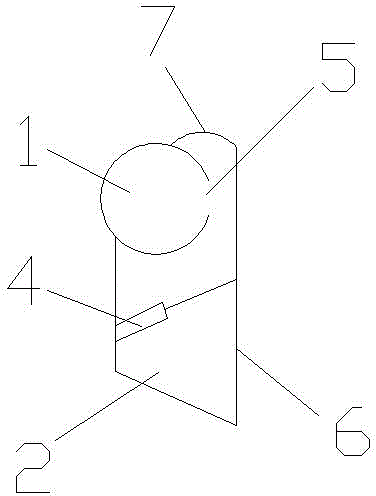

[0021] The specific embodiment is as follows, the dry grass material is put into the blower 3 feed inlet, the dry grass material is blown into the transmission pipeline 1, and the part dry grass material through the discharge port 5 is blown into the storage box 2 with the wind, and after a period of blowing, the storage Filled with hay material in the hopper 2, close the blower 3, start the cylinder 4, and the push rod turns the gate 6 outwards and pushes it out, and the hay material can be slid into the feeding trough by the inclined bottom surface of the material storage box 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com