Automatic numerical control machining equipment applied to guide wheel production

A kind of processing equipment and automatic technology, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems that production enterprises cannot expand large-scale production, cannot further improve productivity, and cannot realize fully automatic processing, so as to reduce processing time , Reduce labor intensity, improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

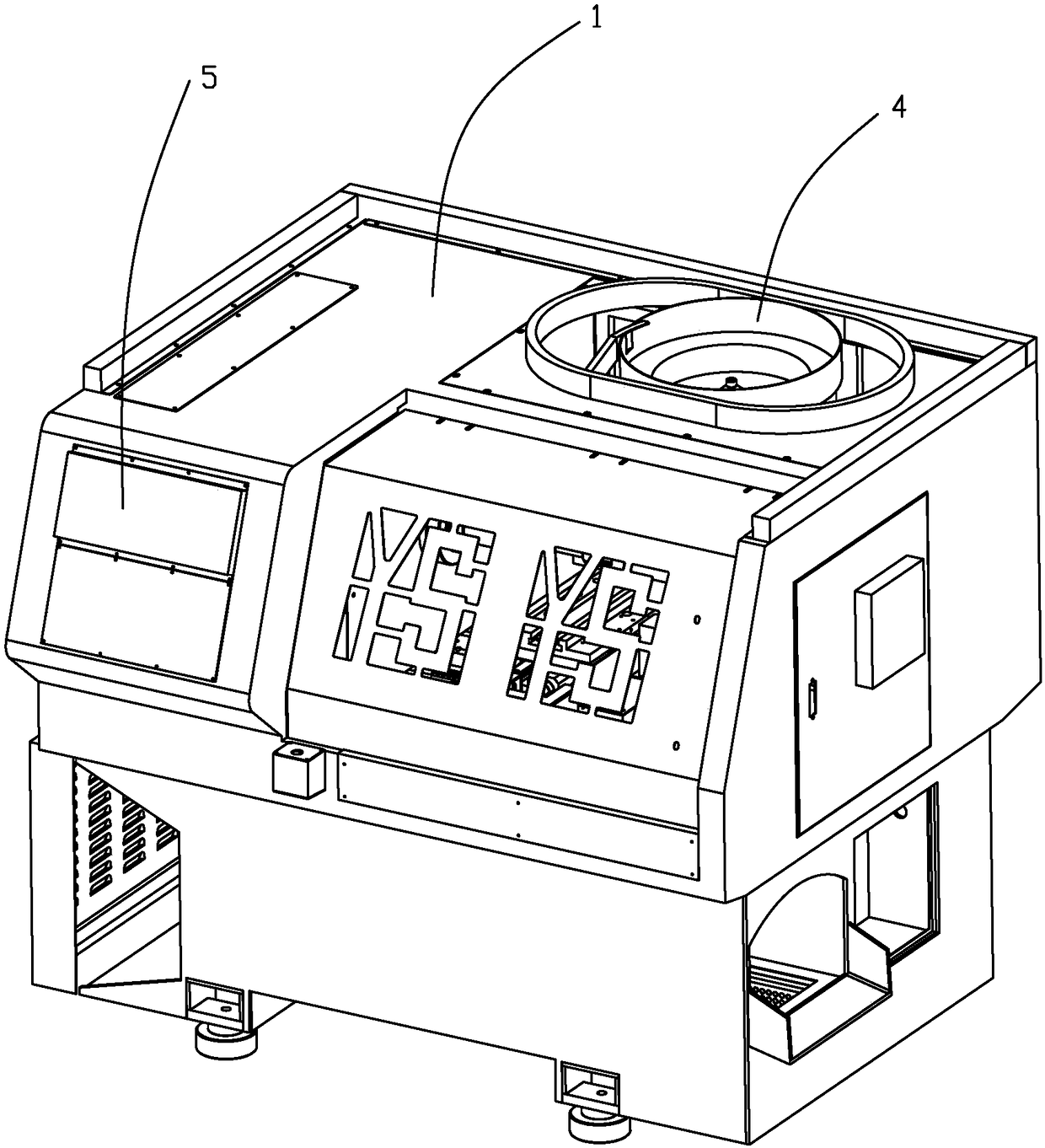

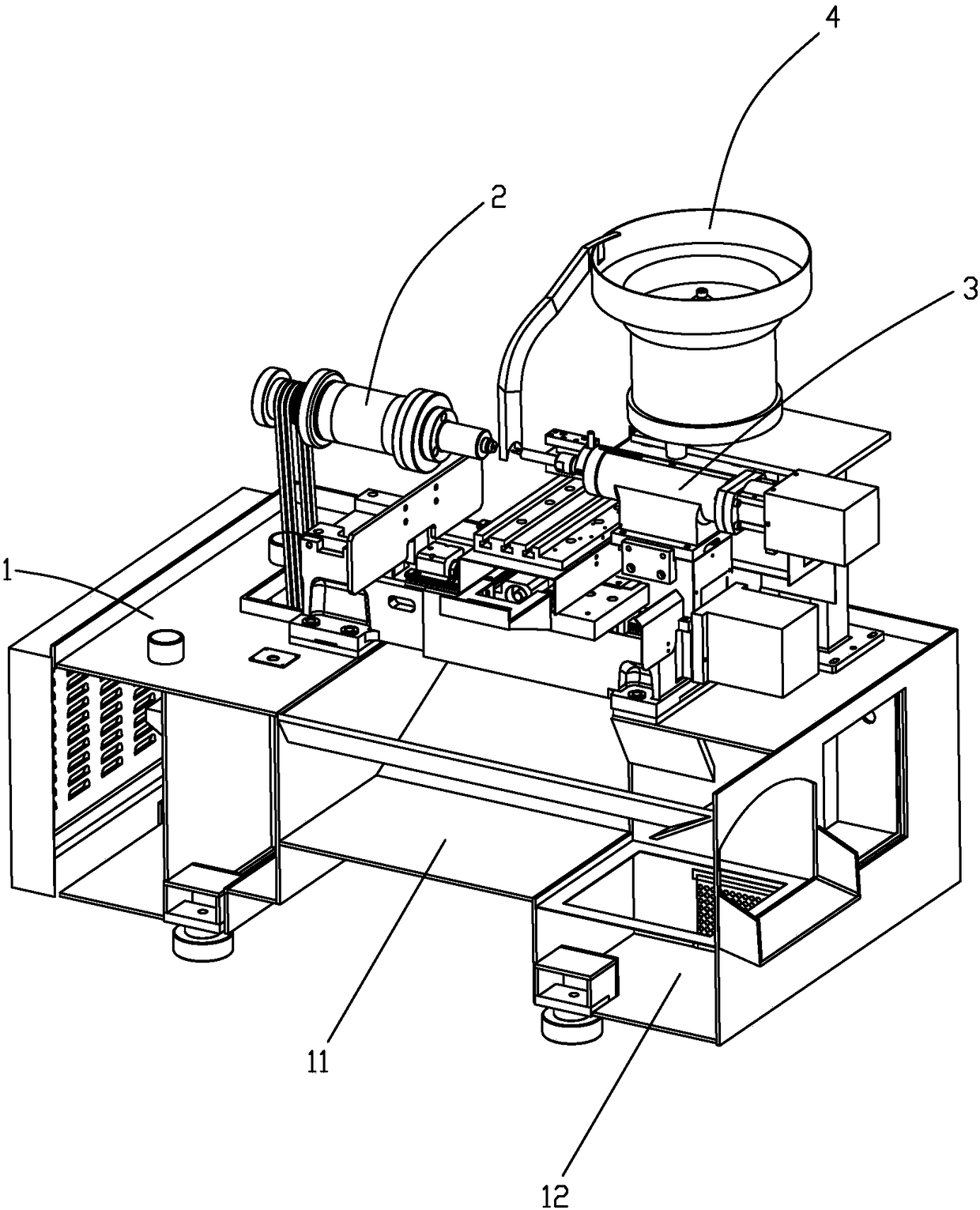

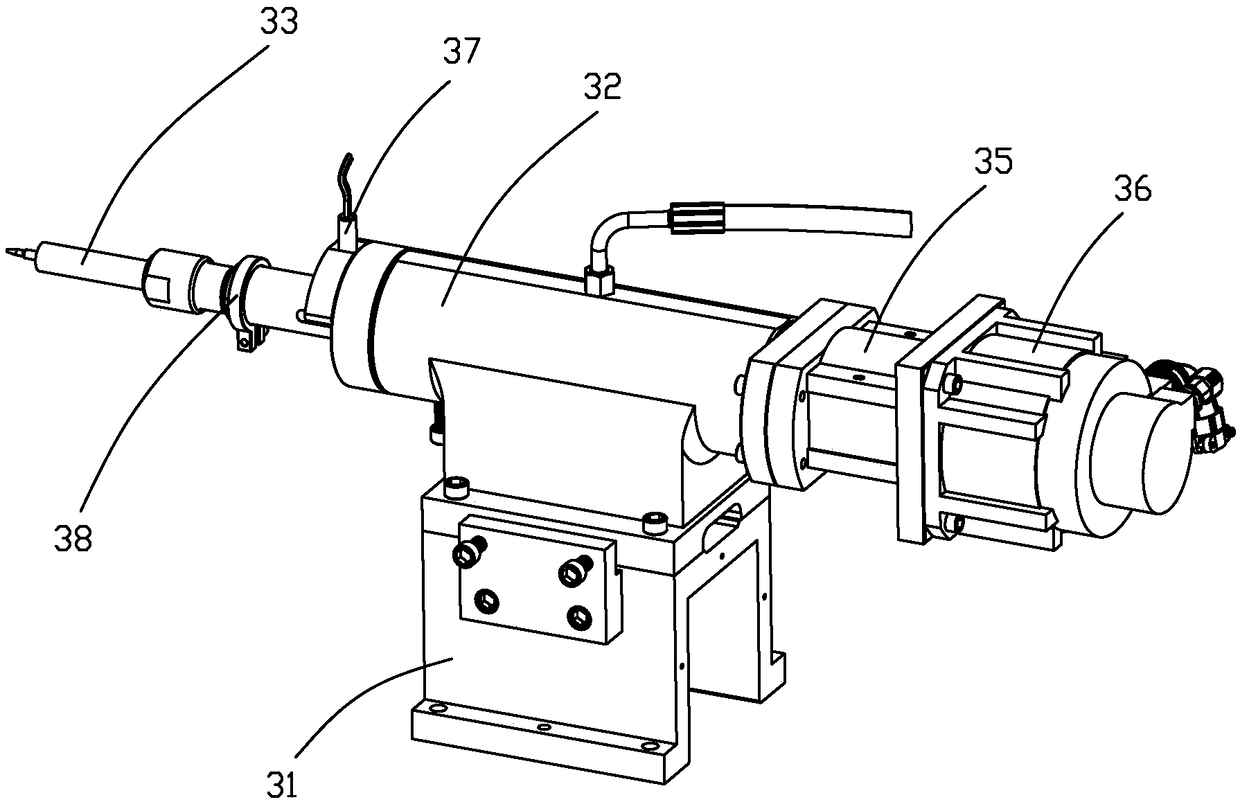

[0059] Such as Figure 1-2 As shown, the automatic numerical control processing equipment used in the production of guide wheels includes frame 1, rotating clamping device 2, constant force tailstock 3, feeding device 4, cutting device, material receiving device, bus numerical control system 5 and pumping components .

[0060] Specifically, the rotating clamping device 2 is arranged on the upper left side of the frame 1 for clamping and rotating the workpiece. The constant force tailstock 3 is arranged on the upper right side of the frame 1, and is used to press the workpiece toward the left side of the frame 1. The feeding device 4 is arranged on the rear upper side of the frame 1 and is used to transport the workpiece between the cutting device 2 and the constant force tailstock 4 . The cutting device is arranged on the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com