Sterilization groove of canned food pasteurizer

A pasteurization machine and canned food technology, applied in the field of canned food processing, can solve the problems of poor sterilization effect and uneven temperature of the sterilization tank, achieve improved sterilization effect, simple structure, and improved heating uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

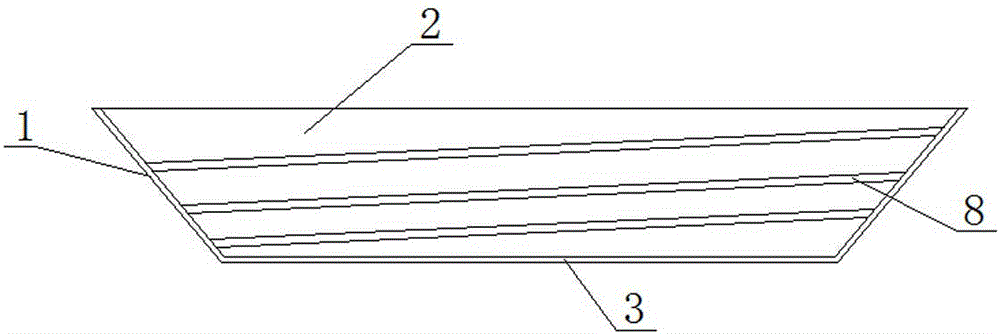

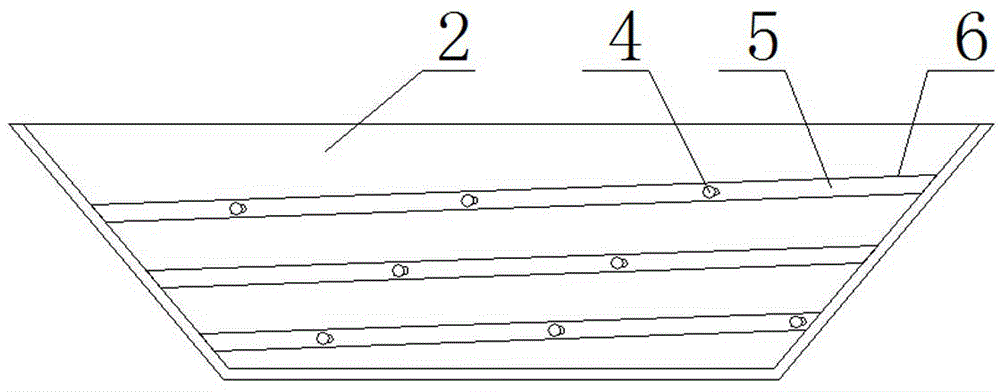

[0038] The sterilization tank of the present embodiment comprises a base plate, the left and right sides of the base plate are connected with side plates, the front and rear sides of the base plate are connected with inclined plates, and the base plate, side plates and inclined plates are connected to form the tank body of the sterilization tank; the tank body The side plate and the inclined plate are provided with a spiral diversion groove, and the spiral direction of the spiral diversion groove is upward; a steam nozzle is arranged in the spiral diversion groove, and the steam nozzle communicates with the external steam source; There are steam jets arranged along the helical direction of the helical diversion groove.

Embodiment 2

[0040] The sterilization tank of the present embodiment comprises a base plate, the left and right sides of the base plate are connected with side plates, the front and rear sides of the base plate are connected with inclined plates, and the base plate, side plates and inclined plates are connected to form the tank body of the sterilization tank; the tank body The side plate and the inclined plate are provided with a spiral diversion groove, and the spiral direction of the spiral diversion groove is upward; a steam nozzle is arranged in the spiral diversion groove, and the steam nozzle communicates with the external steam source; There are steam nozzles arranged along the helical direction of the spiral diversion groove; the nozzles of the steam nozzles in the spiral diversion groove on the side plate are arranged obliquely downward.

Embodiment 3

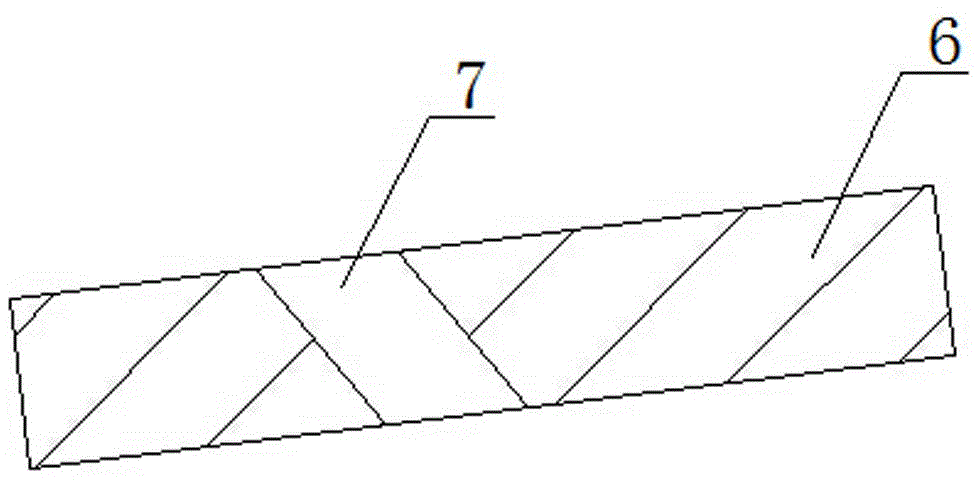

[0042] The sterilization tank of the present embodiment comprises a base plate, the left and right sides of the base plate are connected with side plates, the front and rear sides of the base plate are connected with inclined plates, and the base plate, side plates and inclined plates are connected to form the tank body of the sterilization tank; the tank body The side plate and the inclined plate are provided with a spiral diversion groove, and the spiral direction of the spiral diversion groove is upward; a steam nozzle is arranged in the spiral diversion groove, and the steam nozzle communicates with the external steam source; There are steam nozzles arranged along the spiral direction of the spiral diversion groove; the nozzles of the steam nozzles in the spiral diversion groove on the side plate are arranged obliquely downward; the spiral diversion groove is composed of deflectors arranged on the side plate and the inclined constitute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com