Movable spraying hanging tool

A hanger and hanging board technology, which is applied in the direction of the spraying device, can solve the problems of limited size and volume of the parts to be sprayed, and the shape and size of the parts that cannot be sprayed can be adjusted, so as to achieve the effect of convenient spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

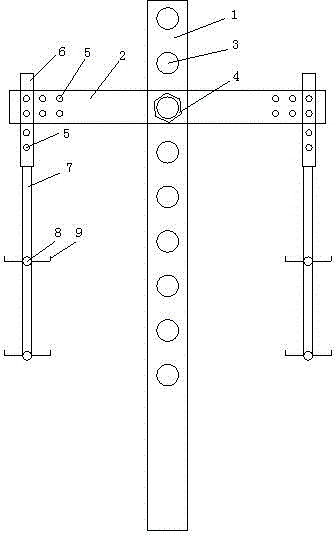

[0014] like figure 1 As shown, a movable spraying hanger of the present invention includes a main shaft 1 and a hanging board 2, the main shaft 1 is provided with a plurality of perforations 3 sequentially from top to bottom, and no less than one hanging board 2 is connected to the main shaft 1. The hanging plate 2 is movably connected with the main shaft 1 through the fixed shaft 4, and the two sides of the hanging plate 2 are provided with position adjustment holes 5 sequentially from the inside to the outside. Adjustment holes 5 are also provided in turn from top to bottom. The bottom and middle of the hanger 7 are provided with horizontal shafts 8 parallel to each other. Both sides of the horizontal shaft 8 are provided with hooks 9. The hooks 9 are L-shaped structures laid flat. 1 is a rotatable rotating shaft.

[0015] The perforation between the main shaft and the hanging plate and the adjustment hole between the hanging plate and the connecting shaft can effectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com