A method and device for detecting the compactness of bulk ballasted bed

A compactness detection and bulk technology, applied in the directions of roads, tracks, measuring instruments, etc., can solve the problems of low measurement accuracy and difficult implementation, and achieve the effect of improving measurement accuracy, easy implementation, and improving test work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

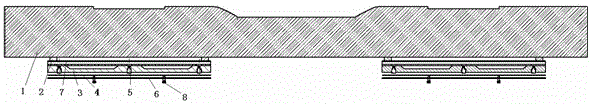

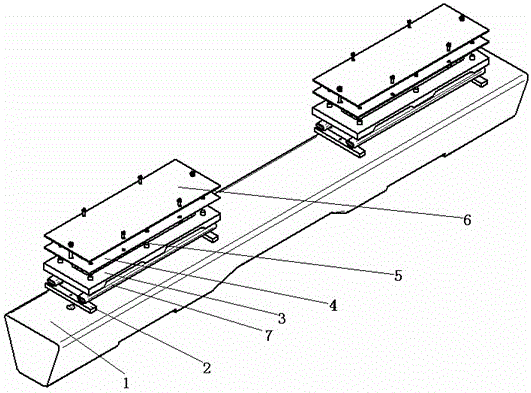

[0038] Example 1: The compactness detection method of the bulk ballasted bed is used as an indoor test for the compactness of the ballasted bed. The test object is a newly built bulky ballasted bed in the laboratory. The material of the ballast is ordinary limestone graded ballast. Cyclic loading and compaction, the details are as follows:

[0039] By measuring the contact strength value between the protective plate at the bottom of the sleeper and the ballast within 5s, the contact strength value is collected every 0.1s, and the average value of each contact strength value is calculated to obtain the average value of the contact strength , to calculate the average contact intensity with specific measurements difference between ,pass Calculate the difference ratio , take the difference ratio The absolute value of ;The measured results are as follows: measurement time 5s, specific measurement value =45MPa, average contact strength =42.4MPa, =5.78%, 5%<5.78%...

Embodiment 2

[0055] Example 2: This bulk ballasted ballast bed density detection method, this method is used to monitor the compactness of the track bed of the outdoor on-site railway line, the test object is the ballasted track bed of the outdoor on-site railway line, the material of the ballast is ordinary granite graded track bed, after nearly one year of construction The repeated action of the trains in the year, the daily average of 20 passenger and freight trains are mixed, the specific content is as follows:

[0056] By measuring the contact strength value between the protective plate at the bottom of the sleeper and the ballast within 8s, the contact strength value is collected every 0.1s, and the average value of each contact strength value is calculated to obtain the average value of the contact strength , to calculate the average contact intensity with specific measurements difference between ,pass Calculate the difference ratio , take the difference ratio The abso...

Embodiment 3

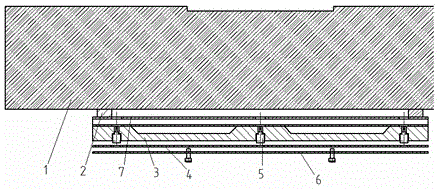

[0073] Embodiment 3: This loose body has ballast bed compactness detection method, and this method is used as indoor test ballast bed compactness detection, and test object is that newly-built loose body has ballast bed in laboratory, and ballast material is ordinary granite rock gradation ballast, After completion, it has undergone 1 million cycles of indoor cyclic loading and compaction. The specific methods are as follows:

[0074]First place a pressure sensor under the ordinary sleeper. The pressure sensor and its circuit must be protected. By measuring the contact strength value between the bottom of the sleeper and the ballast within 10s, the contact strength value is collected every 0.1s, and the average value of each contact strength value is calculated. Contact Intensity Mean , to calculate the average contact intensity with specific measurements difference between ,pass Calculate the difference ratio , take the difference ratio The absolute value of ;T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com