Large ceramic airing frame

A technology for large ceramics and drying racks, which is applied in the direction of drying, dryers, local agitation dryers, etc., which can solve the problems of ceramic damage and easy falls, and achieve the effect of avoiding falls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

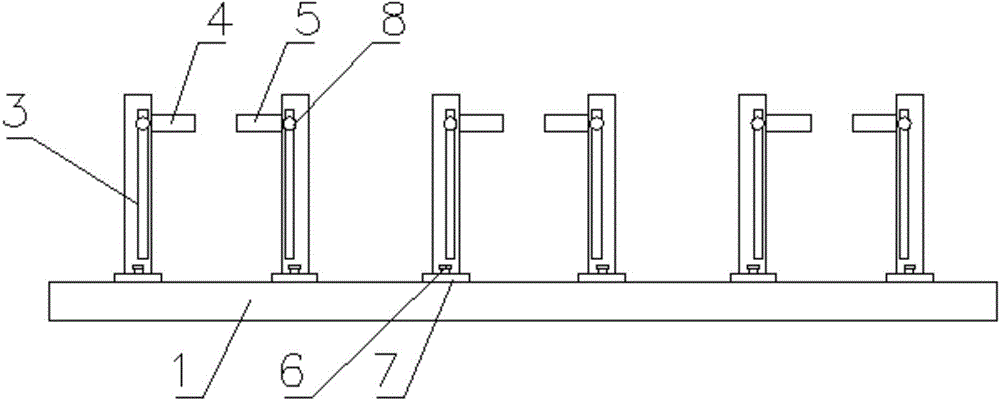

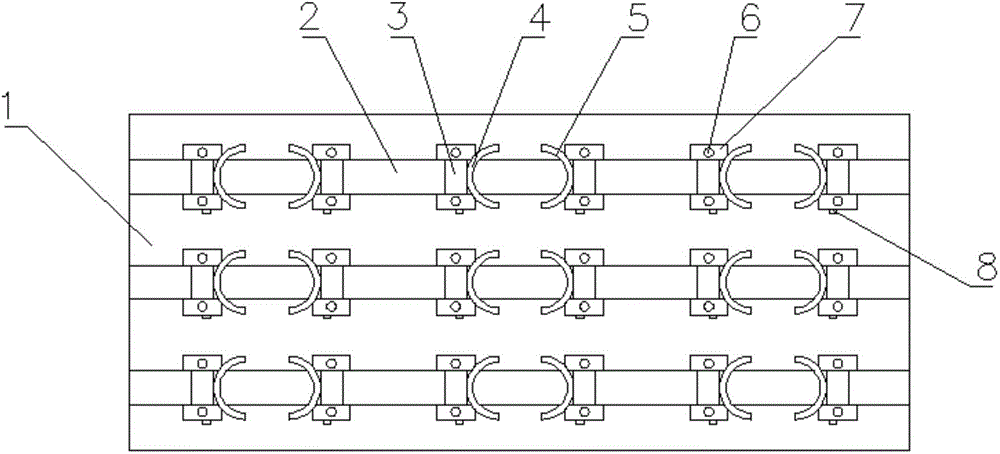

[0012] The following will be further described with reference to the accompanying drawings and in conjunction with specific embodiments, so that those skilled in the art can implement it by referring to the text of the description, and the scope of protection is not limited by the embodiments of the technical solution.

[0013] like figure 1 , figure 2 As shown, a large-scale ceramic drying rack includes: a base 1, a chute 2 and a supporting mechanism, and a plurality of chutes 2 are arranged horizontally and equidistantly in parallel on the base 1, and the chute 2 is a T-shaped groove. A plurality of support mechanisms are installed, and the support mechanisms include: two columns 3, two I-shaped slide seats 7, left splint 4 and right splint 5, two I-shaped slide seats 7 are movable and embedded in the chute 2, two The I-shaped sliding seat 7 is provided with a sliding seat locking screw 6, and the bottom ends of the two columns 3 are respectively fixed and installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com