a connector

A technology of connectors and plug-in terminals, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve problems such as water seepage and damage to connectors, and achieve the effect of ensuring service life and facilitating miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

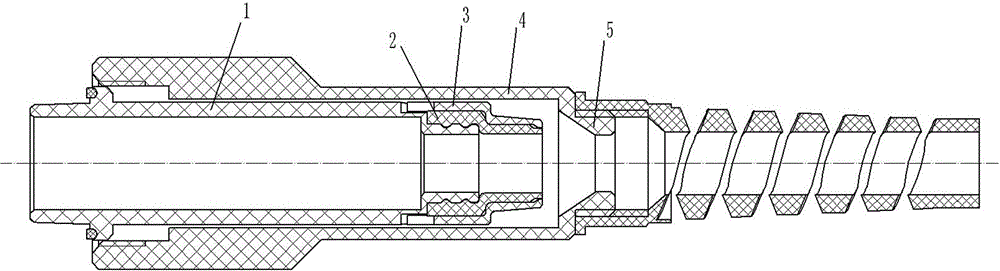

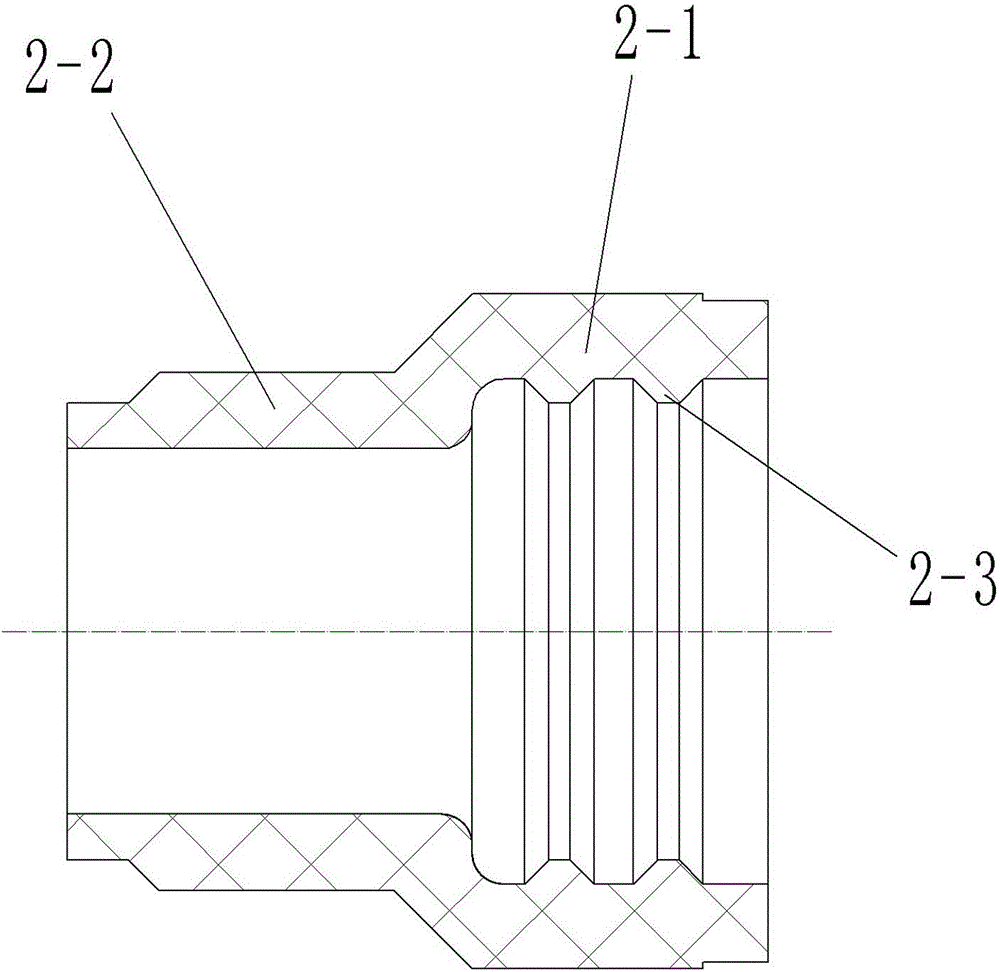

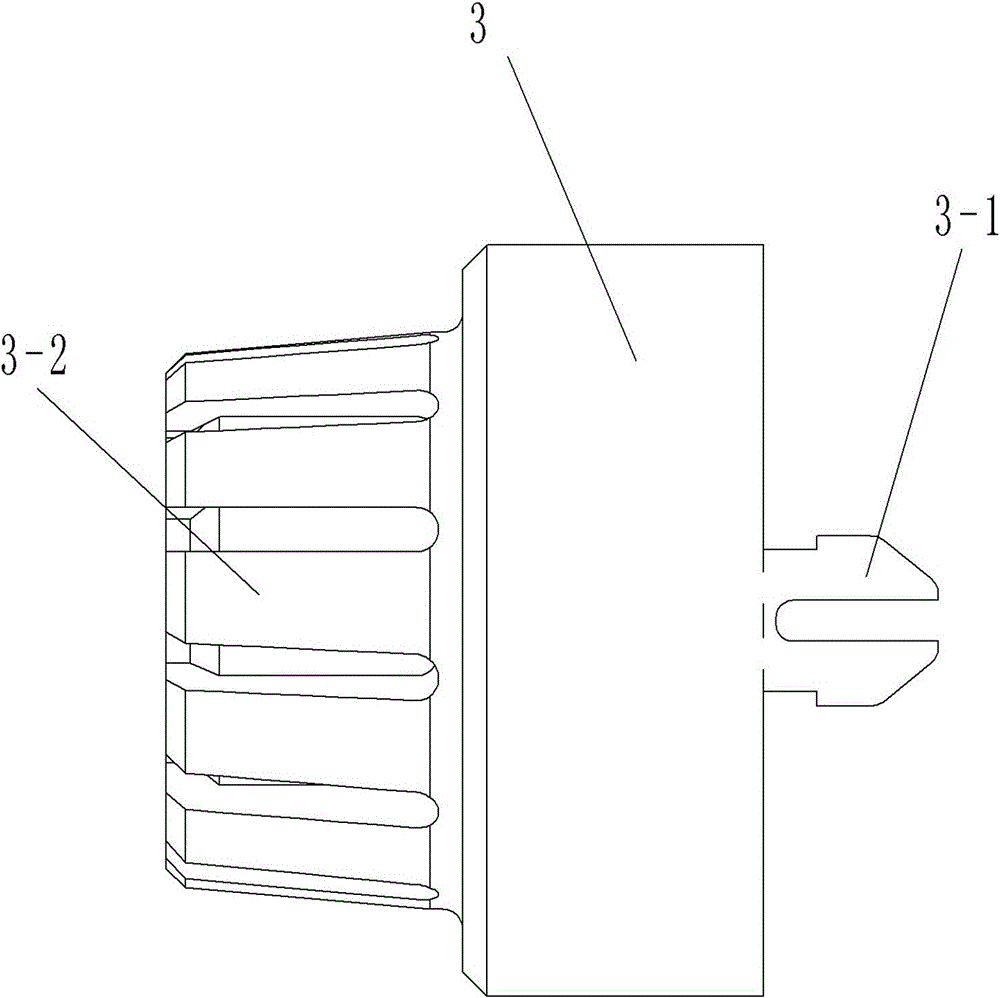

[0019] An example of a connector is Figure 1~4 Shown: including the inner shell 1 whose front end is the plug-in end, the outer periphery of the inner shell is axially movable and has an outer shell 4 in the rotating sleeve, and the front end of the outer shell is provided with a threaded screw for connecting with the corresponding adapter connector shell. The connecting thread installed, the rear end of the outer casing is provided with an inversion edge 5. The inner shell is made of transparent PC material. The inner shell includes a front guide section that guides and cooperates with the outer shell and a rear installation section whose outer diameter is smaller than the front guide section. The connector also includes an elastic sealing sleeve 2, an elastic sealing sleeve The wire sleeve includes a wire seal body. The front end of the wire seal body is provided with a wire seal fixed section 2-1 which is fitted with an interference seal on the rear installation section. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com