Pearl factory indoor cultivation system

A breeding system and factory-like technology, applied in fish farming, climate change adaptation, application, etc., can solve the problems of single power, easy accumulation of dirt, limited sewage treatment capacity, etc., to facilitate processing and transportation, reduce labor intensity, The effect of saving land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

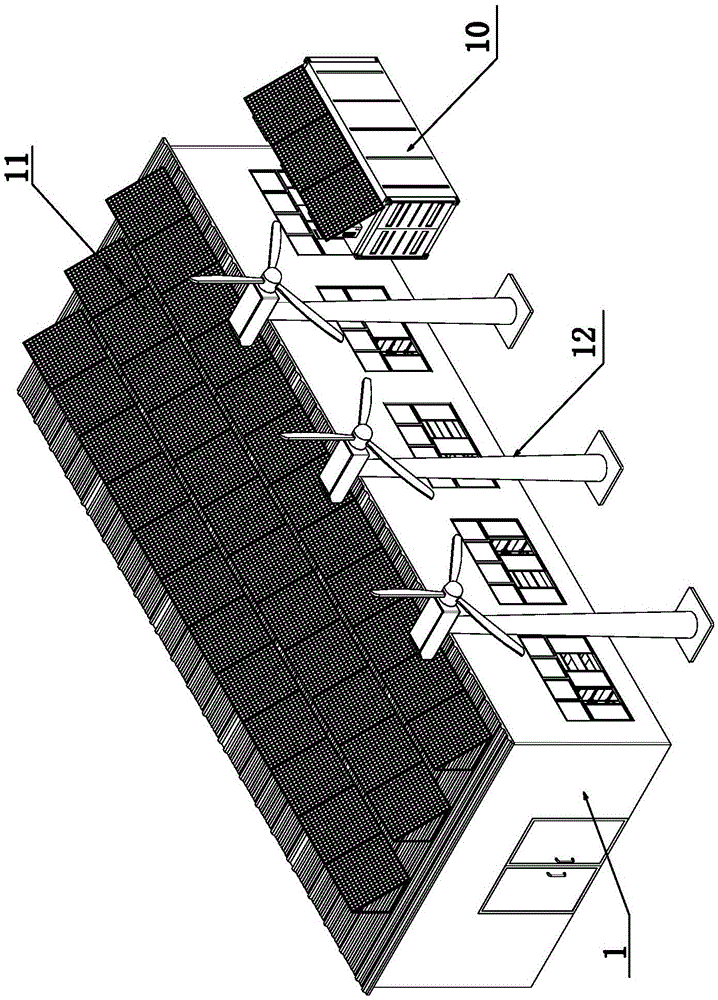

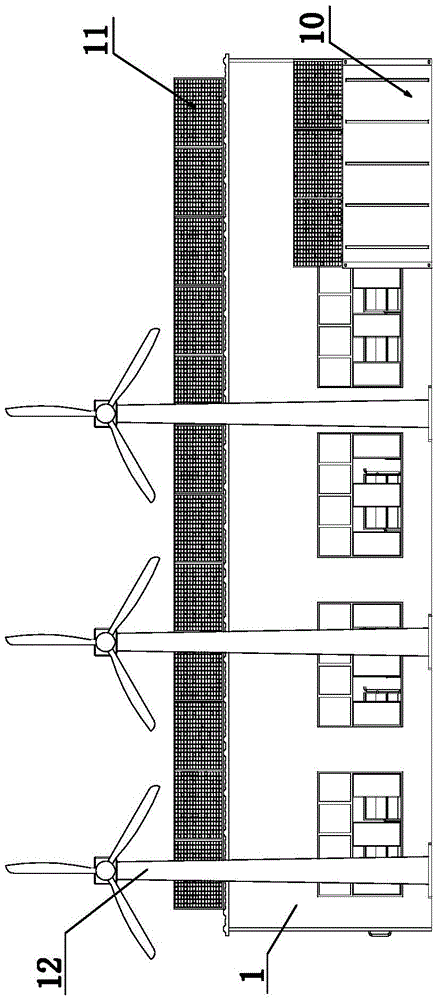

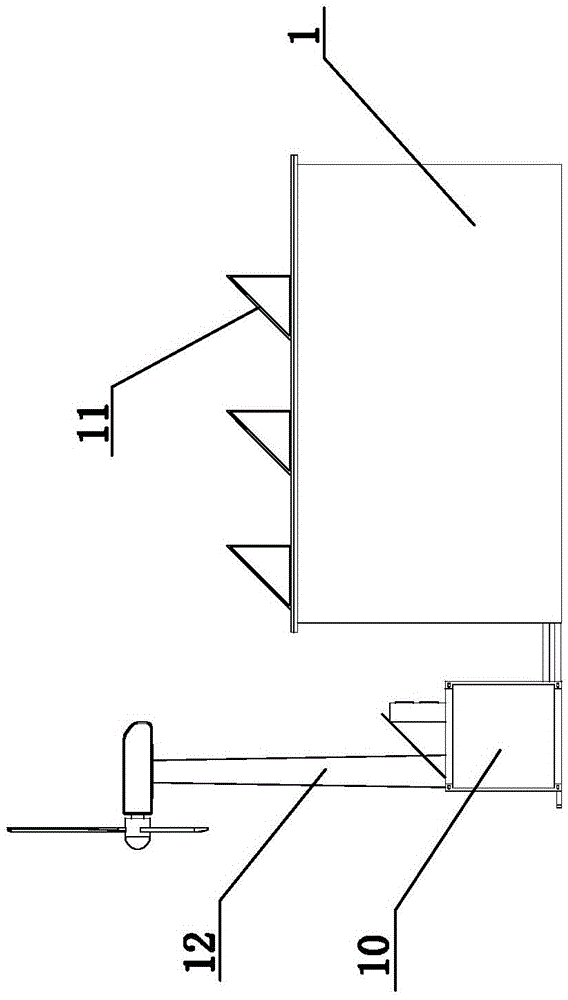

[0022] refer to Figure 1 to Figure 4 , pearl industrialized indoor cultivation system, comprising cultivation chamber 1 and reservoir 2, cultivation chamber 1 is provided with a number of cultivation pond units 3 stacked in layers, cultivation basket 4 is suspended in cultivation pond unit 3, and each cultivation pond unit passes through The pipelines are collectively connected to the reservoir 2, and each breeding pond unit is connected to the reservoir 2 through the water supply pipeline 5 and the return pipeline 6 respectively. The water supply pipeline is provided with a water supply control valve and a water supply pump, and the return pipeline is provided with a return pipeline. Water control valve, filtering device 8 and return water pump 9, water supply control valve, water supply pump, return water control valve and return water pump a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com